Preparation method and application of solidified microsphere type fertilizer for soil remediation

A technology of soil remediation and microspheres, which is applied in the direction of solid/semi-solid fertilizers, application, calcium fertilizers, etc. It can solve the problems of secondary release, low phytoremediation efficiency, and interference with normal cultivation of crops, etc., so that the materials are convenient and easy to obtain , to avoid the risk of secondary pollution, to avoid the effect of toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

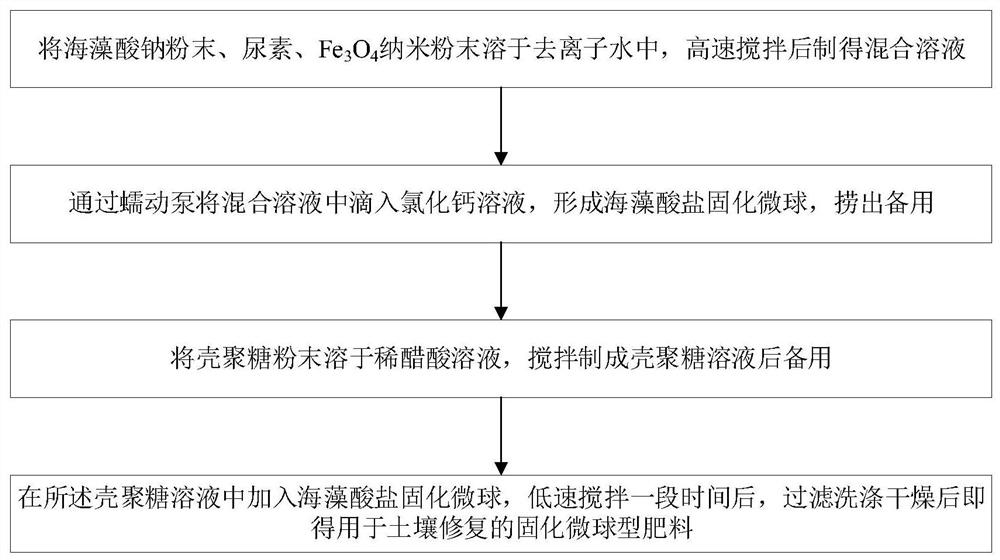

[0032] like figure 1 Shown, the application is a kind of solidified microsphere type fertilizer preparation method for soil restoration, comprising:

[0033] Sodium alginate powder, urea, Fe 3 o 4 The nano powder is dissolved in deionized water, and the mixed solution is obtained after high-speed stirring;

[0034] Drop the calcium chloride solution into the mixed solution through the peristaltic pump, and the alginate solidified microspheres form the alginate solidified microspheres, and take them out for later use;

[0035] Dissolve chitosan powder in dilute acetic acid solution, stir to make chitosan solution and set aside;

[0036] Add alginate solidified microspheres into the chitosan solution, stir at a low speed for a period of time, filter, wash and dry to obtain the solidified microsphere fertilizer for soil restoration.

[0037] In one embodiment, the mass content of sodium alginate in the mixed solution is 1wt%-3wt%.

[0038] In another embodiment, the urea pow...

Embodiment 1

[0053] (1) The preparation of solidified microsphere fertilizer is as follows:

[0054] Weigh 4.00g sodium alginate powder, 5.00g urea powder and 1.00g nano Fe 3 o 4 Put the powder in a beaker, add 200mL of deionized water to dissolve, and stir under 600r / min magnetic force for 2h to obtain a uniform mixed solution. Weigh 6g of anhydrous calcium chloride powder and place it in a 500mL beaker, add 400mL of deionized water to make a solution. The mixed solution was dripped into the calcium chloride solution through a peristaltic pump with an inner diameter of 2 mm to form alginate solidified microspheres, which were then taken out for later use.

[0055] Weigh 4.00g of chitosan powder and place it in a beaker, add 200mL of dilute acetic acid solution with a concentration of 1%, stir for 2h under magnetic stirring at 600r / min, after forming a uniform solution, add alginate solidified microspheres, Stir at a stirring speed of 100r / min for 30min, take it out, wash it with deioni...

Embodiment 2

[0064] (1) The preparation of solidified microsphere fertilizer is as follows:

[0065] Weigh 4.00g of sodium alginate powder, 5.00g of urea powder and 1.00g of nano-Fe3O4 powder into a beaker, add 200mL of deionized water to dissolve, and stir under 600r / min magnetic force for 2h to obtain a uniform mixed solution. Weigh 6g of anhydrous calcium chloride powder and place it in a 500mL beaker, add 400mL of deionized water to make a solution. The mixed solution was dripped into the calcium chloride solution through a peristaltic pump with an inner diameter of 2 mm to form alginate solidified microspheres, which were then taken out for later use.

[0066] Weigh 4.00g of chitosan powder and place it in a beaker, add 200mL of dilute acetic acid solution with a concentration of 1%, stir for 2h under magnetic stirring at 600r / min, after forming a uniform solution, add alginate solidified microspheres, Stir at a stirring speed of 100r / min for 30min, take it out, wash it with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com