Plastic hollow board

A technology of hollow boards and plastics, applied in the direction of layered products, etc., can solve the problems of unbalanced load-bearing capacity and poor comprehensive strength of hollow boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

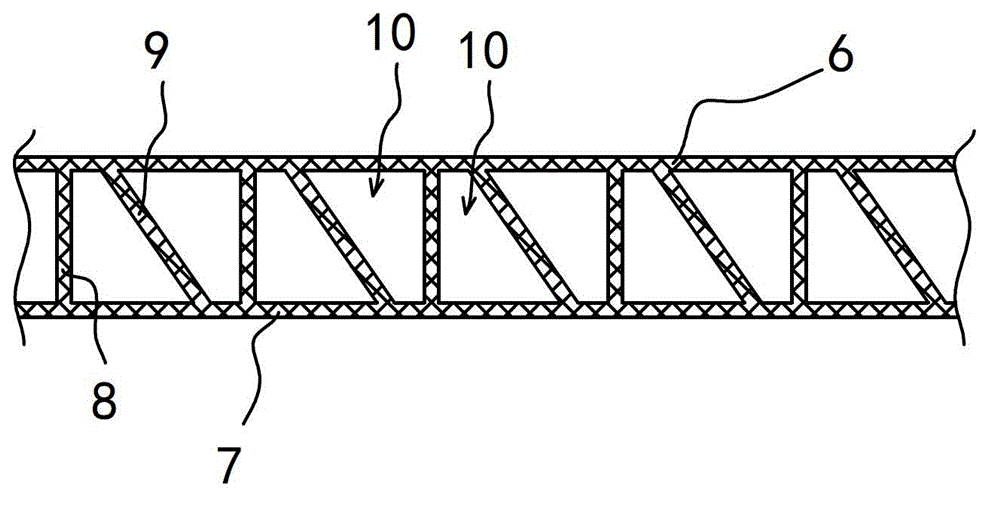

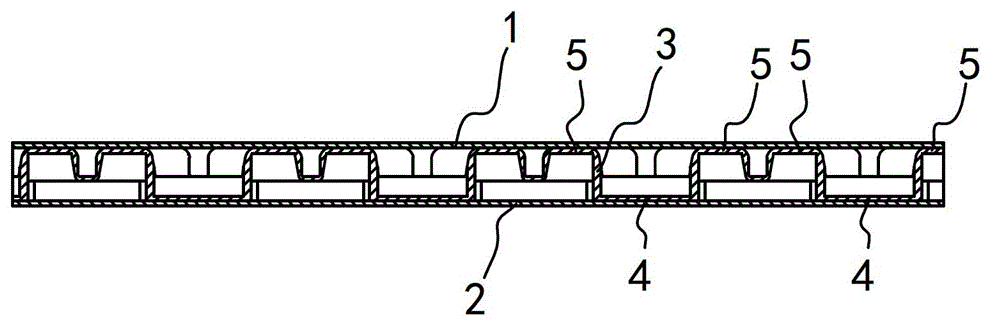

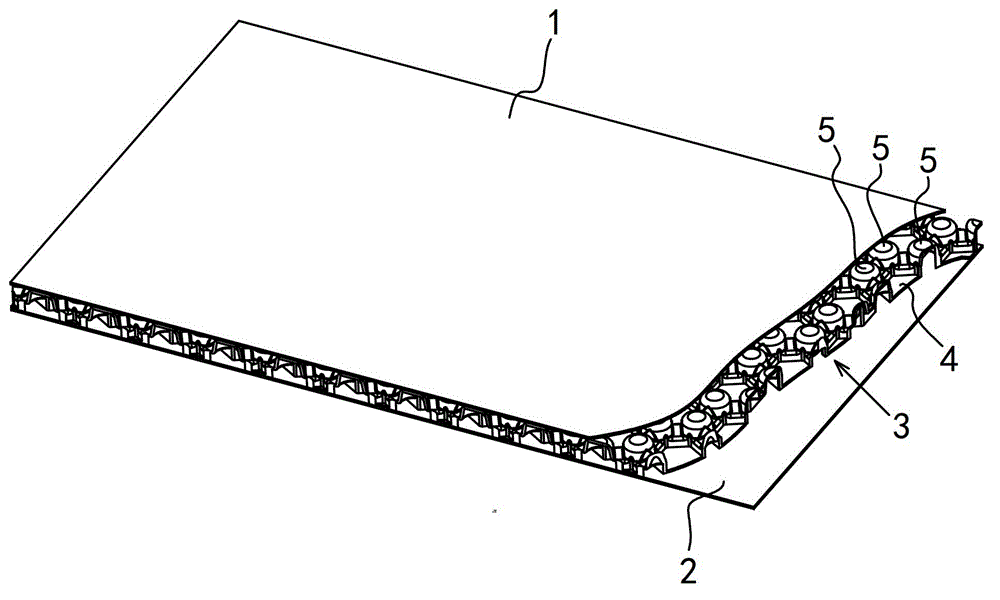

[0024] Example: see attached Figure 2-5 as shown,

[0025] A plastic hollow board comprises an upper plastic surface layer 1 and a lower plastic surface layer 2, and an intermediate layer 3 is arranged between the upper plastic surface layer 1 and the lower plastic surface layer 2, and the intermediate layer 3 is a plastic plate.

[0026] The plastic plate is evenly distributed with forward arches 4, the forward arch 4 is a hexagonal prism with a regular hexagonal cross-section formed by the downward deformation and arching of the plastic plate. The 4 forward arches on the upper surface are concave, while the 4 forward arches on the lower surface of the plastic plate are convex.

[0027] Reverse arches 5 are embedded between adjacent forward arches 4 on the plastic plate, and each reverse arch 5 is arranged around the forward arches 4, and corresponds to the regular hexagon located at the forward arches 4. of the six corners. The reverse arch 5 is a cylindrical body formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com