Catalytic treatment process and system for converting hazardous waste oil-containing silt into solid waste

A catalytic treatment, mud sand technology, applied in the direction of sludge treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult to realize resource utilization, pollutant discharge, etc., to alleviate ecological environment problems, The effect of high oil content and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

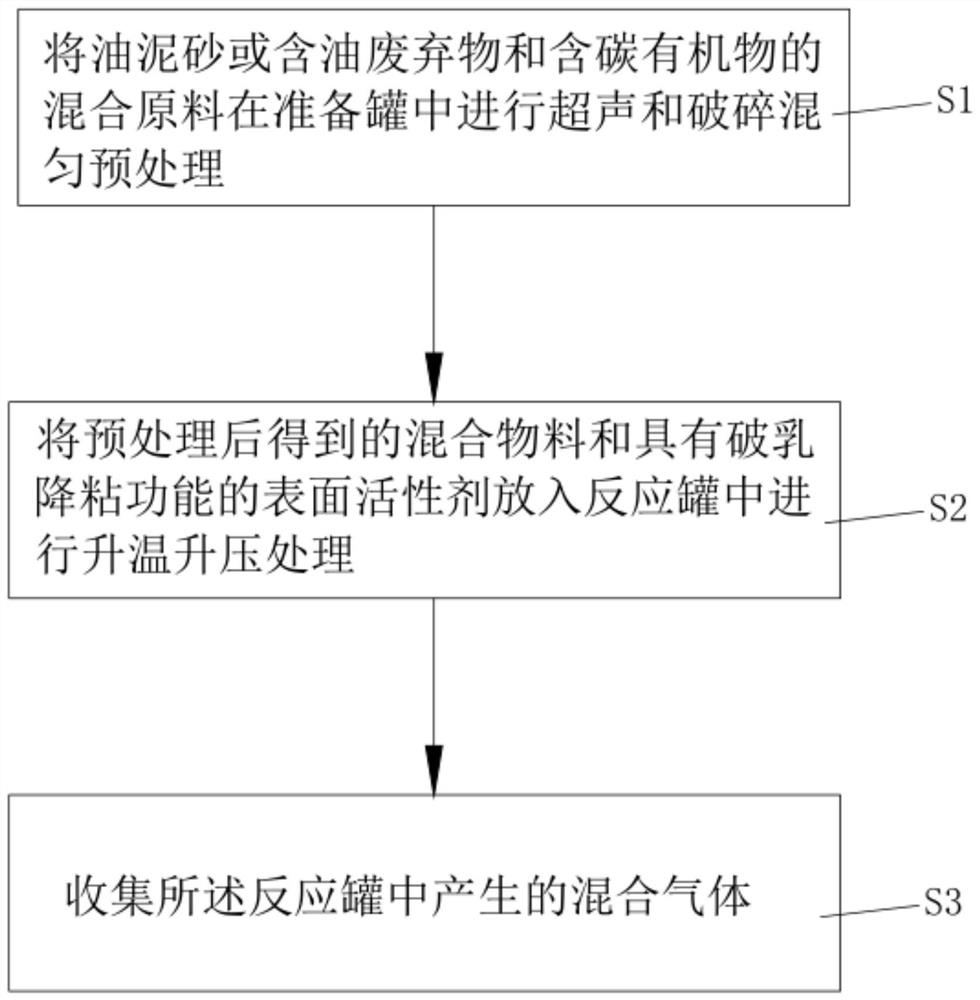

[0038] Such as figure 1 A catalytic treatment process for converting hazardous waste oily mud sand into solid waste is shown, including the following steps:

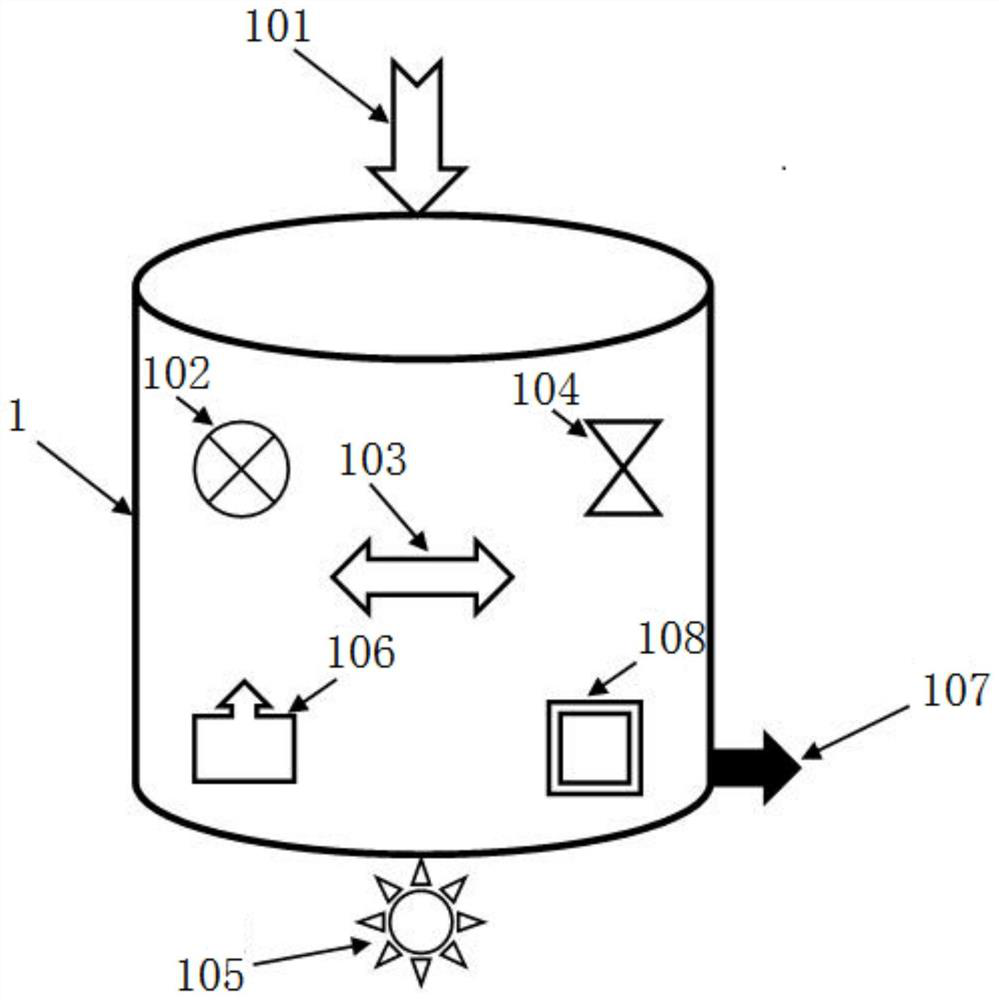

[0039] S1. The mixed raw material of oily sludge sand or oily waste and carbon-containing organic matter is pretreated by ultrasonication, crushing and mixing in the preparation tank 1 . Wherein, the temperature of the mixed raw materials in the preparation tank 1 is controlled between 20-100°C.

[0040] Specifically, oily sand or oily waste includes a mixture of one or more of oily sludge, oily bottoms, drilling mud, and oily sludge; organic waste.

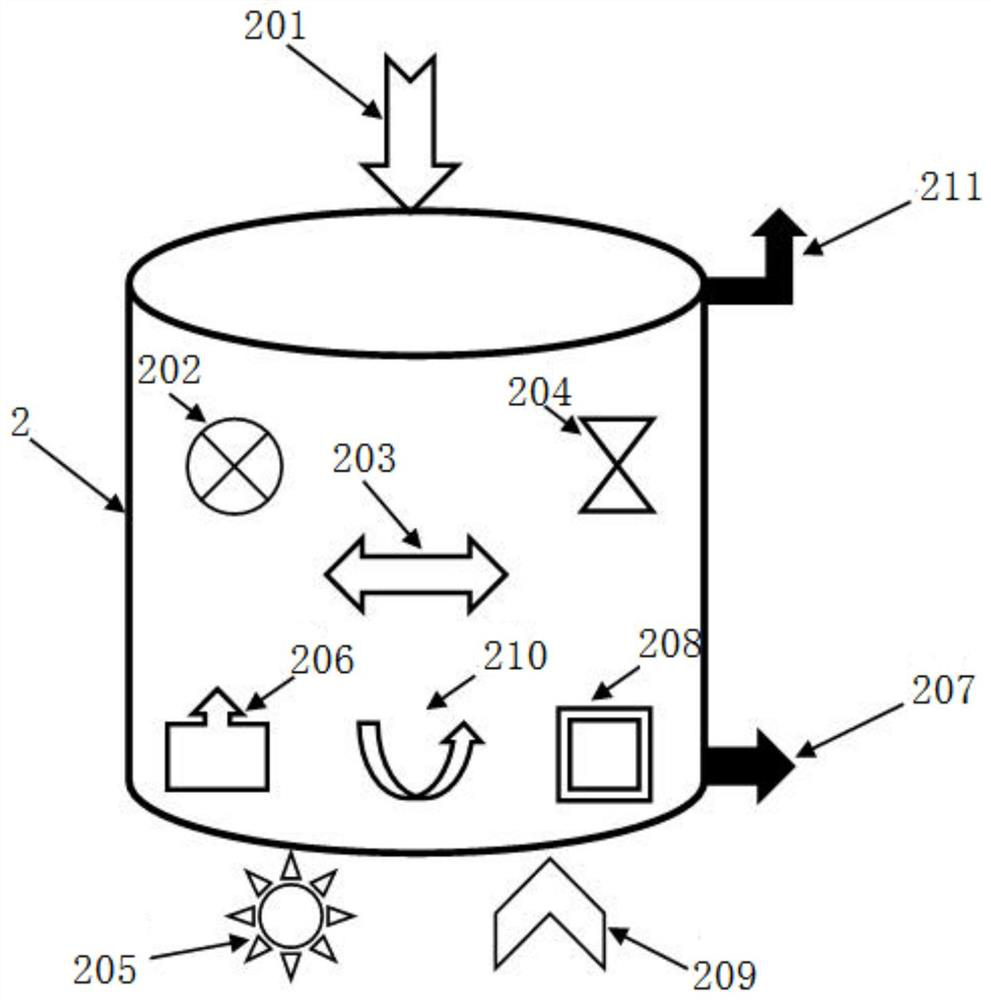

[0041] S2. Put the mixed material obtained after pretreatment and the surfactant having the function of demulsification and viscosity reduction into the reaction tank 2 for temperature raising and pressure raising treatment. Wherein, the temperature of the mixed material in the reaction tank 2 is controlled between 100-500°C.

[0042] Concrete, the mass ratio of each co...

Embodiment 2

[0051] Such as Figure 4 As shown, the present invention also provides a catalytic treatment system for converting hazardous waste oily mud sand into solid waste, including a preparation tank 1 , at least one reaction tank 2 and an exhaust gas treatment system 3 . The preparation tank 1, the reaction tank 2 and the waste gas treatment system 3 all adopt the preparation tank 1, the reaction tank 2 and the waste gas treatment system 3 described in the first embodiment above, and will not be repeated here.

[0052]To sum up, the catalytic treatment process and system for converting hazardous waste oily mud sand into solid waste provided by the embodiment of the present invention adopts the method of combining low-temperature hydrothermal carbonization pyrolysis and surfactant to convert oily mud sand and carbon-containing sand into solid waste. Organic matter is the main raw material. After the pretreatment in the preparation tank 1, it is transferred to the reaction tank 2 for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com