Belt accumulated slag cleaning device

A technology for cleaning devices and belts, which is applied in the directions of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of belt jitter and can not completely clean the belt, etc., and achieve the effect of controlling jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

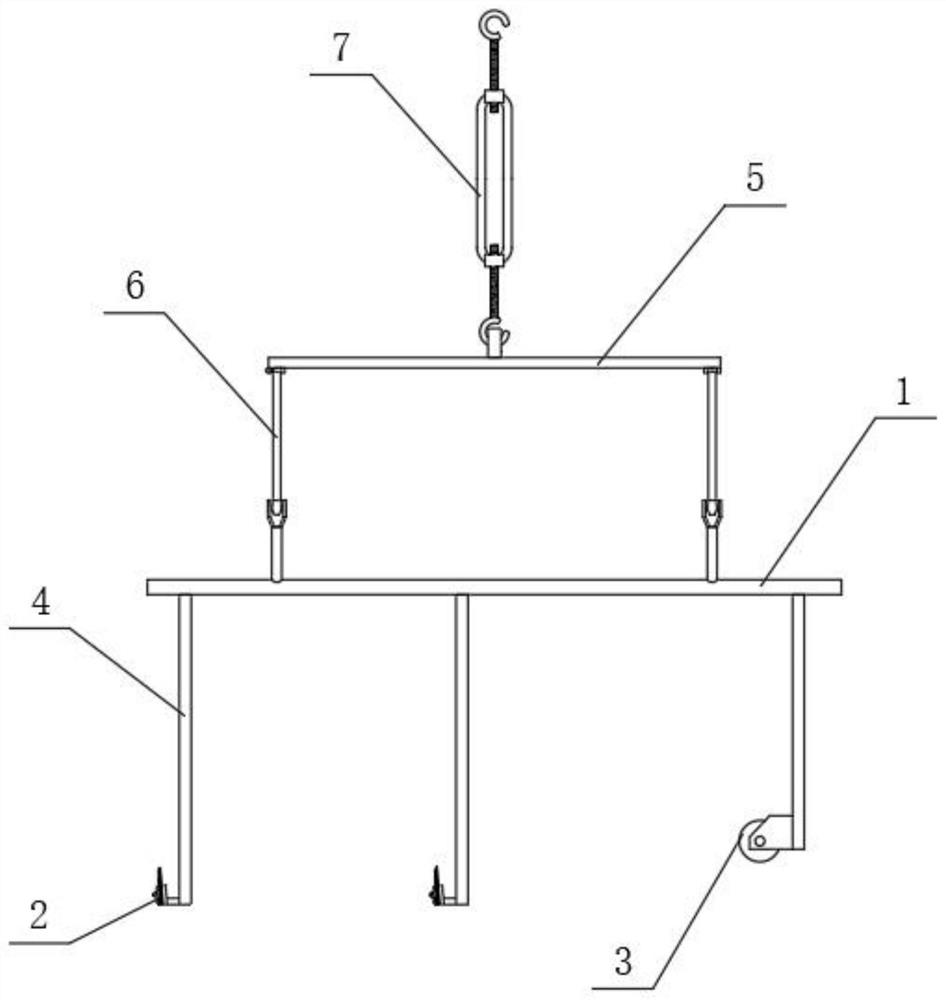

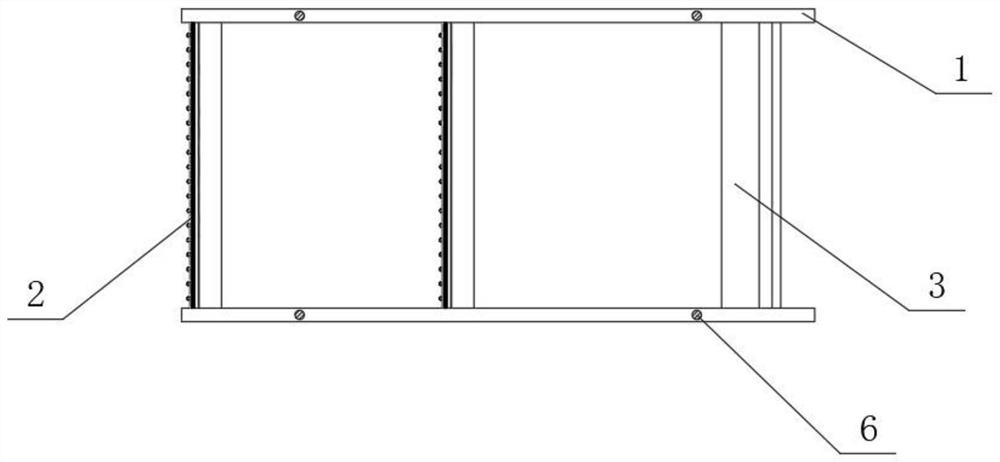

[0026] Embodiment 1: the most basic unit that realizes the function of the present invention

[0027] A belt slag cleaning device includes a main crossbar 1, and a roller 3 is arranged below the main crossbar 1 via a connecting rod 4.

Embodiment 2

[0028] Example 2: In order to deal with the belt cleaner not installed on the belt conveyor

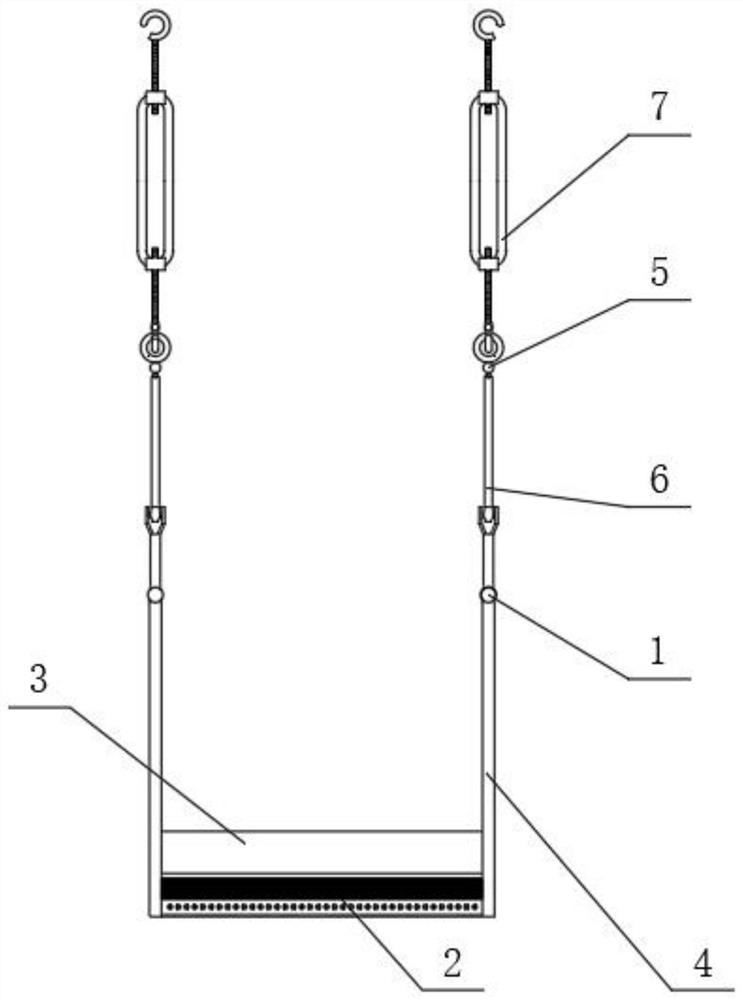

[0029] On the basis of Example 1, a scraper 2 is provided below the main crossbar 1 through a connecting rod 4

Embodiment 3

[0030] Embodiment 3: Increase the suspension structure of the main crossbar

[0031] On the basis of Embodiment 2, the main crossbar 1 is connected with the auxiliary crossbar 5 through the suspension rod 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com