Anti-static plastic film and production process thereof

A technology of plastic film and production process, applied in the direction of coating, etc., can solve the problems affecting the range of use and damage of plastic film, achieve excellent anti-dust effect, improve bonding performance, and reduce the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

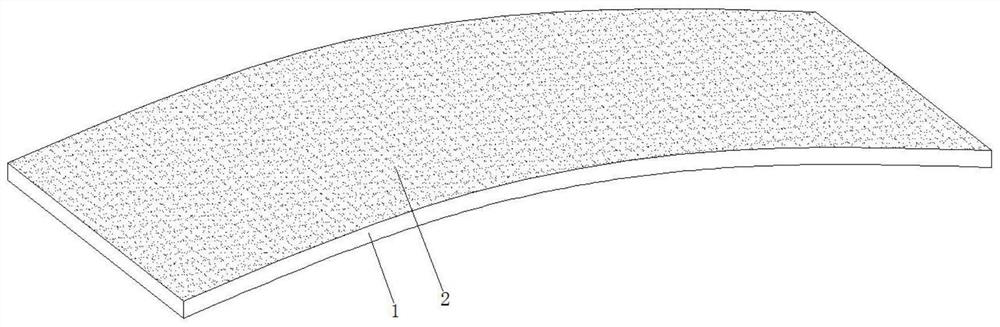

[0027] refer to Figure 1-3 , an antistatic plastic film, comprising a film body 1, the outer walls of both sides of the film body 1 are coated with an antistatic coating 2.

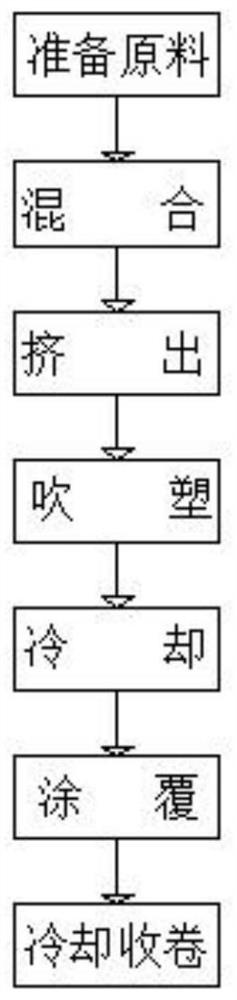

[0028] Among the present invention, its production technology of a kind of antistatic plastic film comprises the following steps:

[0029] S1: Prepare the raw materials, prepare the raw materials in a certain proportion, and then preheat the raw materials through the drying equipment;

[0030] S2: Mixing, pouring the preheated raw materials into the mixing tank in turn and stirring evenly, raising the temperature in the mixing tank while stirring, and controlling the temperature in the mixing tank within the range of 90 degrees Celsius to 100 degrees Celsius;

[0031] S3: Extrusion, inject raw materials into the extruder, extrude the tubular parison through the extruder, control the extrusion temperature within the range of 150 degrees Celsius to 175 degrees Celsius, and pay attention to dust prevention...

Embodiment 2

[0038] refer to Figure 1-3 , an antistatic plastic film, comprising a film body 1, the outer walls of both sides of the film body 1 are coated with an antistatic coating 2.

[0039] Among the present invention, its production technology of a kind of antistatic plastic film comprises the following steps:

[0040] S1: Prepare the raw materials, prepare the raw materials in a certain proportion, and then preheat the raw materials through the drying equipment;

[0041] S2: Mixing, pouring the preheated raw materials into the mixing tank in turn and stirring evenly, raising the temperature in the mixing tank while stirring, and controlling the temperature in the mixing tank within the range of 90 degrees Celsius to 100 degrees Celsius;

[0042] S3: Extrusion, inject raw materials into the extruder, extrude the tubular parison through the extruder, control the extrusion temperature within the range of 150 degrees Celsius to 175 degrees Celsius, and pay attention to dust prevention...

Embodiment 3

[0049] refer to Figure 1-3 , an antistatic plastic film, comprising a film body 1, the outer walls of both sides of the film body 1 are coated with an antistatic coating 2.

[0050] Among the present invention, its production technology of a kind of antistatic plastic film comprises the following steps:

[0051] S1: Prepare the raw materials, prepare the raw materials in a certain proportion, and then preheat the raw materials through the drying equipment;

[0052] S2: Mixing, pouring the preheated raw materials into the mixing tank in turn and stirring evenly, raising the temperature in the mixing tank while stirring, and controlling the temperature in the mixing tank within the range of 90 degrees Celsius to 100 degrees Celsius;

[0053] S3: Extrusion, inject raw materials into the extruder, extrude the tubular parison through the extruder, control the extrusion temperature within the range of 150 degrees Celsius to 175 degrees Celsius, and pay attention to dust prevention w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com