Lubricating oil blending process

A lubricating oil and blending technology, which is applied in the direction of lubricating compositions, chemical instruments and methods, mixers, etc., can solve the problems of high impurity content and poor mixing effect, achieve high viscosity increasing ability, uniform and thorough mixing, and improve viscosity temperature performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

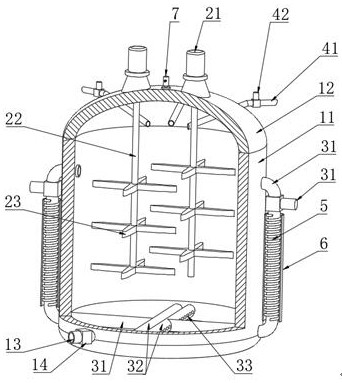

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0059] For convenience of description, the following description concepts are introduced in the writing of the present invention:

[0060] In the present invention, 'front', 'back', 'left', 'right', 'upper', 'down' all refer to Figure 5 The orientation in , where 'front' refers to the Figure 5 facing outward relative to the paper, 'after' refers to the Figure 5 The center faces inwards relative to the paper. In the description of the present invention, it should be noted that, unless otherwise specified and limited, the terms "installed", "set with", "sleeved / connected", "connected", etc. should be understood in a broad sense, such as " Connection" can be a fixed connection, a detachable connection, or an integral connection; it can be a mechanical connection or an electrical connection; it can be a direct connection or an indirect connection through an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com