Backlight module, backlight module manufacturing method and display device

A technology for backlight modules and display devices, applied in optics, nonlinear optics, instruments, etc., can solve the problems of thick backlight film layer and difficulty in obtaining uniform light mixing, and achieve the effect of light and thin structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

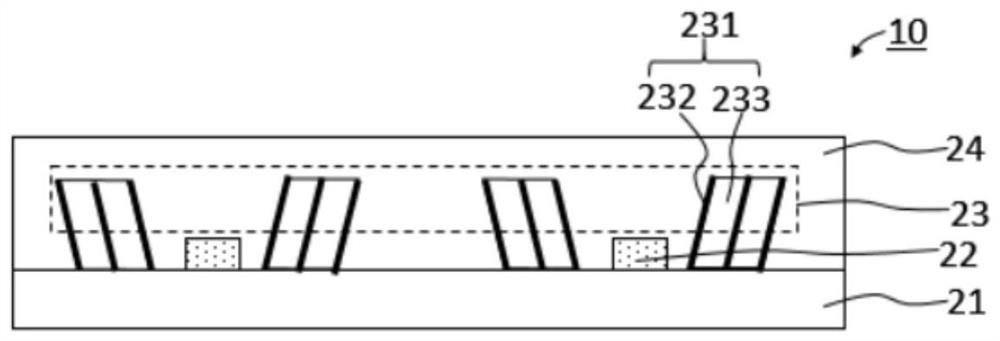

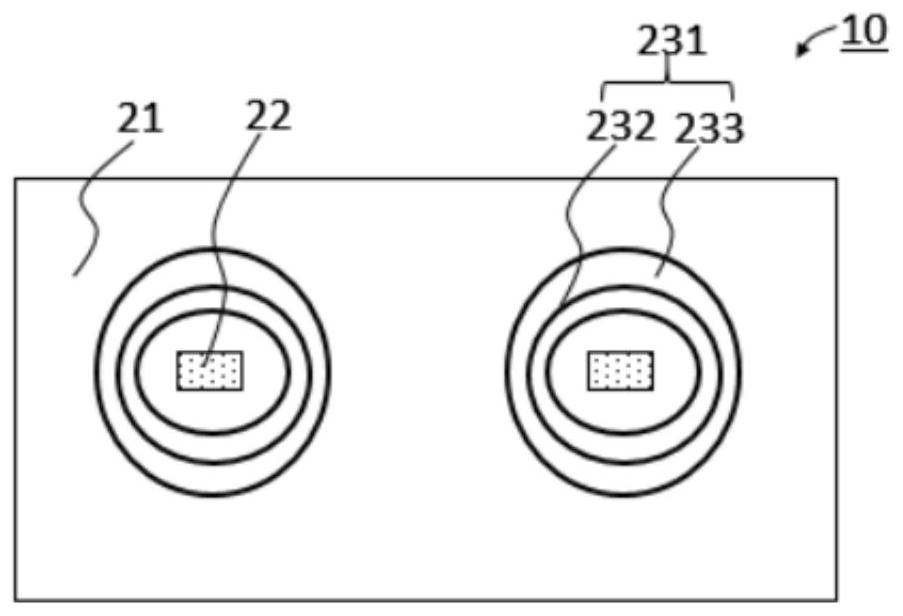

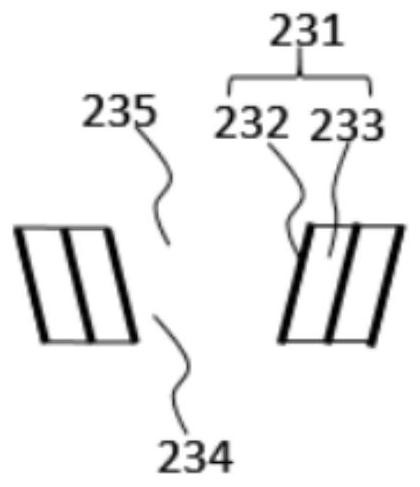

[0040] see figure 1 , figure 2 , image 3 , figure 1 It is a schematic diagram of the first cross-sectional structure of the backlight module provided in the embodiment of the present application, figure 2 It is a schematic diagram of the first top view structure of the backlight module provided by the embodiment of the present application, image 3 A schematic cross-sectional structure diagram of a transflective unit provided in an embodiment of the present application.

[0041] The embodiment of the application provides a backlight module 10 . The backlight module 10 includes a substrate 21 , a light emitting diode 22 , a transflective layer 23 and an encapsulation layer 24 . The light-emitting diode 22 is arranged on the base 21; the transflective layer 23 is arranged on the base, the transflective layer 23 includes a plurality of transflective units 231, and the transflective unit 231 includes at least one transparent carrier film layer 233 and at least one A transf...

Embodiment 2

[0061] see Figure 7 , Figure 7 It is a schematic diagram of the third cross-sectional structure of the backlight module provided by the embodiment of the present application. The structure of the embodiment of the present application is the same or similar to that of the first embodiment. In the direction away from the light emitting diode 22 , the thickness of the transflective film layer 232 of the same transflective unit 231 increases or decreases gradually.

[0062] Specifically, the light emitted by the light emitting diode 22 has the maximum brightness when passing through the nearest first semi-transparent reflective film layer 232, and the brightness decreases when it reaches the second semi-transparent reflective film layer 232, and reaches the third semi-transparent reflective film layer. When the film layer 232, the brightness is further reduced, and the thickness of the semi-transparent reflective film layer 232 of the same semi-transparent reflective unit 231 i...

Embodiment 3

[0066] see Figure 8 , Figure 9 to Figure 15 , the embodiment of the present application also provides a backlight module manufacturing method, Figure 8 A schematic diagram of the process steps of the backlight module manufacturing method provided by the embodiment of the present application is shown, Figure 9 to Figure 15 The manufacturing process of the backlight module is illustrated. The backlight module manufacturing method of this embodiment can be used to manufacture the backlight module 10 of any one of the above-mentioned embodiments. The backlight module manufacturing method includes the following manufacturing steps: step S100, step S200, step S300, step S400, step S500, Step S600.

[0067] Step S100, such as Figure 9 As shown, a mold substrate 30 is provided, including a plurality of recesses 31 in the mold substrate 30 .

[0068] Specifically, such as Figure 9 As shown, a mold substrate 30 is provided, the mold substrate 30 includes a plurality of depre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com