Double-jacquard warp knitted fabric and knitting process thereof

A technology of jacquard warp and knitted fabric, applied in the field of double jacquard warp knitted fabric and its weaving process, to achieve the effects of rich expression, saving post-processing workload and high burst value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Example 1, non-matching two-color jacquard double jacquard warp knitted fabric manufacturing method

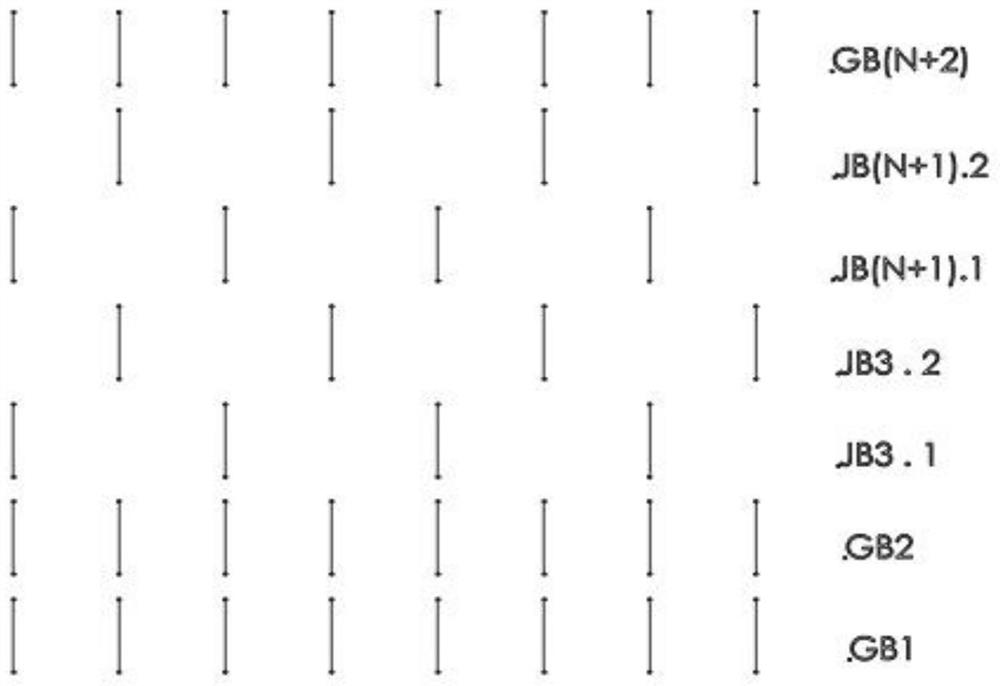

[0039] S1. Machine selection: such as figure 2 As shown, starting from the front of the needle, there are two sets of ground yarn GB1, GB2, one set of Jacquard JB3.1, JB3.2, floral yarn group PB4-PB43, one set of Jacquard JB44.1, JB44.2, A pair of weft inlay combs GB45, this time N=43, a total of 40 pattern combs. The gauge of the machine is 24E with a working width of 132 inches.

[0040] S2. Yarn threading of the machine: such as image 3 As shown, GB1, GB2, JB3.1, JB3.2, JB44.1, JB44.2, GB45 adopt the full wear method. PB4-PB43 is determined according to the characteristics of the pattern, and there are cases where threading is selected or not.

[0041] S3. Laying needle movement method: GB1, GB2, JB3.1, JB3.2 adopt loop forming technology (including open loop and closed loop), JB44.1, JB44.2 adopt weft inserting technology, bar overall needle The back traverse...

example 2

[0052] Example 2, the three-color jacquard double jacquard warp knitted fabric manufacturing method of pad mesh

[0053] S1. Machine selection: such as figure 2 As shown, starting from the front of the needle, there are two sets of ground yarn GB1, GB2, one set of Jacquard JB3.1, JB3.2, flower yarn group PB4-PB51, one set of Jacquard JB52.1, JB52.2, A pair of weft insertion combs GB53, this time N=51, a total of 48 flower combs. The gauge of the machine is 24E with a working width of 132 inches.

[0054] S2. Yarn threading of the machine: such as Figure 4 As shown, GB1, GB2, JB3.1, JB3.2 adopt the method of one wear and one empty, and JB52.1, JB52.2, GB53 adopt the method of full wear. PB4-PB51 is determined according to the characteristics of the pattern, and there are cases where threading is selected or not.

[0055] S3. Laying needle movement method: GB1, GB2, JB3.1, JB3.2 adopt loop forming technology (including open loop forming and closed loop forming), JB52.1, JB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com