Compound enzyme for softening leather as well as preparation method and application of compound enzyme

A leather softening and compound enzyme technology, applied in the field of leather processing, can solve the problems of poor product stability, cross infection, heavy odor, etc., and achieve the effect of promoting penetration and softening, ensuring stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

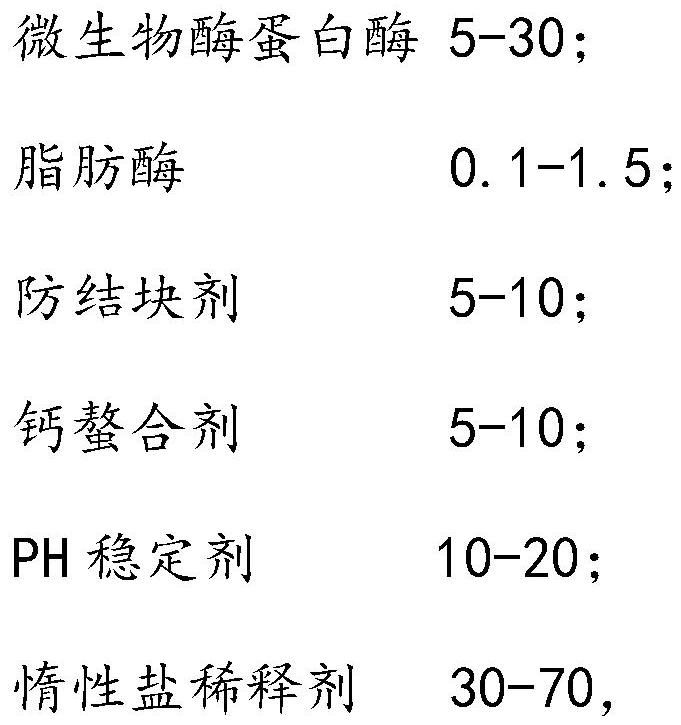

[0028] Get the optimal pH value of 7.0-9.0, 10kg of NB115 microbial trypsin (Sichuan Dawei Science and Technology Co., Ltd.) whose enzyme activity is 30,000 units / g, and LKT lipase (Shandong Long Kete Enzyme Preparation Co., Ltd.) 1kg; Sawdust 5kg; Disodium edetate 5kg; Disodium hydrogen phosphate 5kg; Sodium citrate 5kg; Ammonium sulfate 10kg; preparation.

[0029] With the compound enzyme preparation for leather softening obtained in the above-mentioned embodiment, the yellow cowhide is softened separately after deliming, and the steps are as follows:

[0030] Take 100 kg of the top layer of yellow cowhide after soaking in water, dehairing, liming, peeling, and deliming according to the conventional method (based on the mass of the top layer of gray hide after peeling), put it into the drum, add about 50 kg of water, and adjust the temperature to 35 ℃, add 1.0 kg of compound enzyme preparation for leather softening prepared according to the above formula (or weigh each comp...

Embodiment 2

[0037] Getting the most suitable pH value is 7.0-9.0, enzyme activity is 15kg of JD18 microbial trypsin of 20,000 units / g, and enzyme activity is 1kg of LKT lipase (Shandong Longkete Enzyme Preparation Co., Ltd.) of 100,000 units / g; 9kg of sawdust; 10kg of disodium edetate; 10kg of boric acid; 5kg of sodium citrate; 5kg of ammonium sulfate; 30kg of sodium sulfate and 15kg of sodium chloride;

[0038]Take 100kg of the top layer of yellow cowhide that has been soaked in water, dehaired, limed and peeled according to the conventional method, put it into the drum, add about 20kg of water, adjust the temperature to 33°C, and add the compound enzyme preparation for leather softening prepared according to the above formula 1.0kg (or according to the formula of the above-mentioned compound enzyme, weigh each component according to the same dosage ratio and then add them to the drum), rotate for about 120 minutes, drain, wash and pickle, chrome tan, retan, Fatliquor and drying are proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com