Preparation mold and preparation method of special filler for constructed wetland

A technology of constructed wetlands and molds, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem that there is no good balance between the density of air holes and the overall structural strength, ignoring constructed wetlands The overall structural strength of the special filler, the effect of the maximum efficiency, etc., to achieve the effect of increasing strength, reducing weight, and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

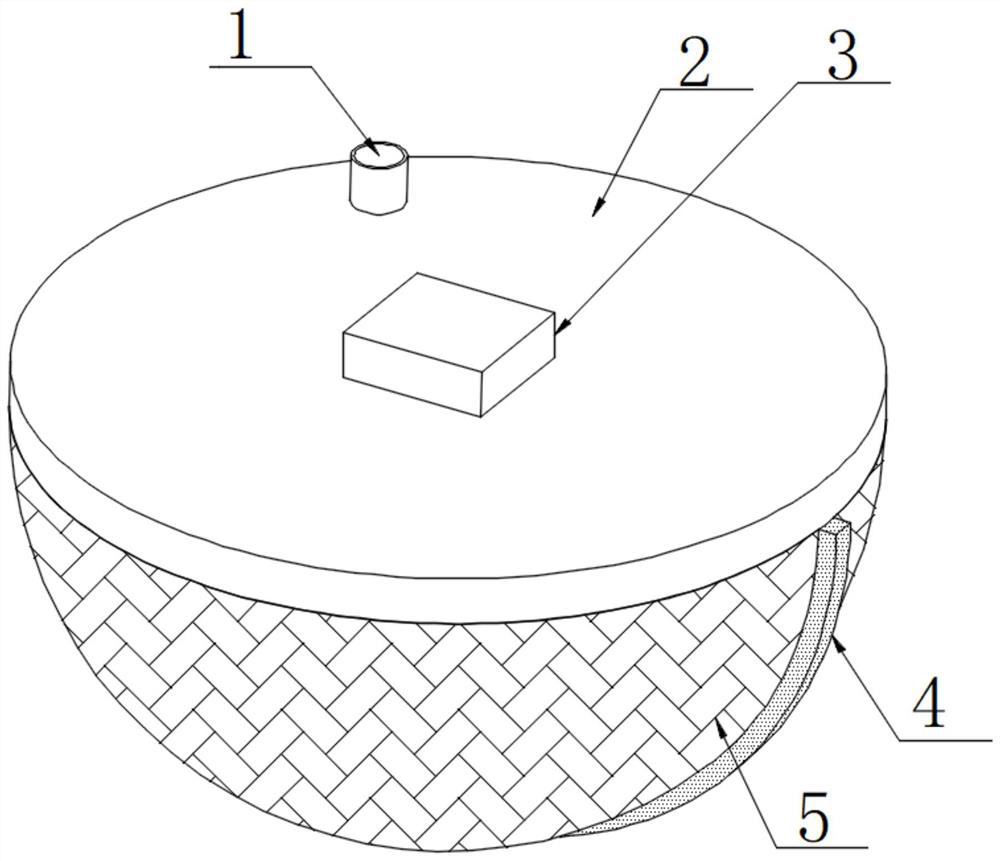

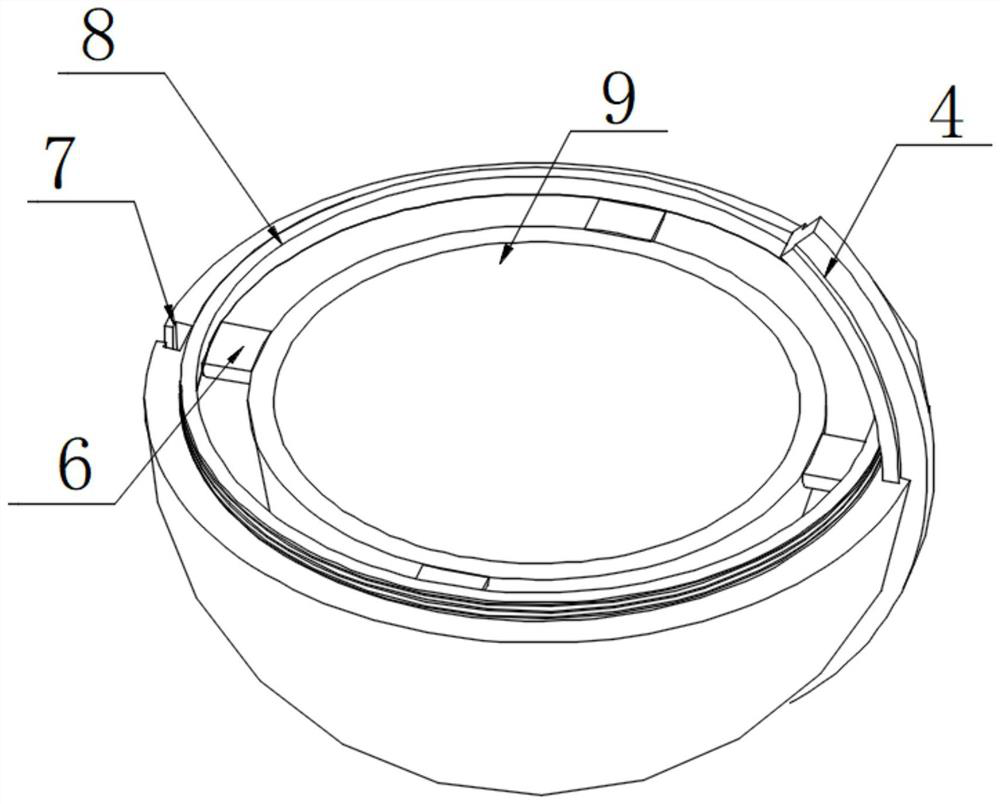

[0032] A mold for preparing special fillers for artificial wetlands, which also includes a lower mold 5 and an upper mold 2 matching its top. The lower mold 5 is in two detachable parts, and a limiting chute 7 is formed between them. The limiting chute 7. The inside is slidingly connected to the limit ring 4. A part of the top of the lower mold 5 is fixedly connected to a fixed ring 8. The outer side of the fixed ring 8 is processed with external threads. The inner mold 9 with the same center of circle is arranged inside the lower mold 5. A plurality of circular hole columns 6 are evenly and fixedly connected, and the outer sides of the plurality of circular hole columns 6 are all in contact with the inner wall of the lower mold 5 .

[0033] The bottom of the upper mold 2 is provided with an annular fixed ring groove 10, and the outer circle of the fixed ring groove 10 is processed with an internal thread on the upper mold 2, and the upper mold 2 is compatible with the external...

Embodiment 1

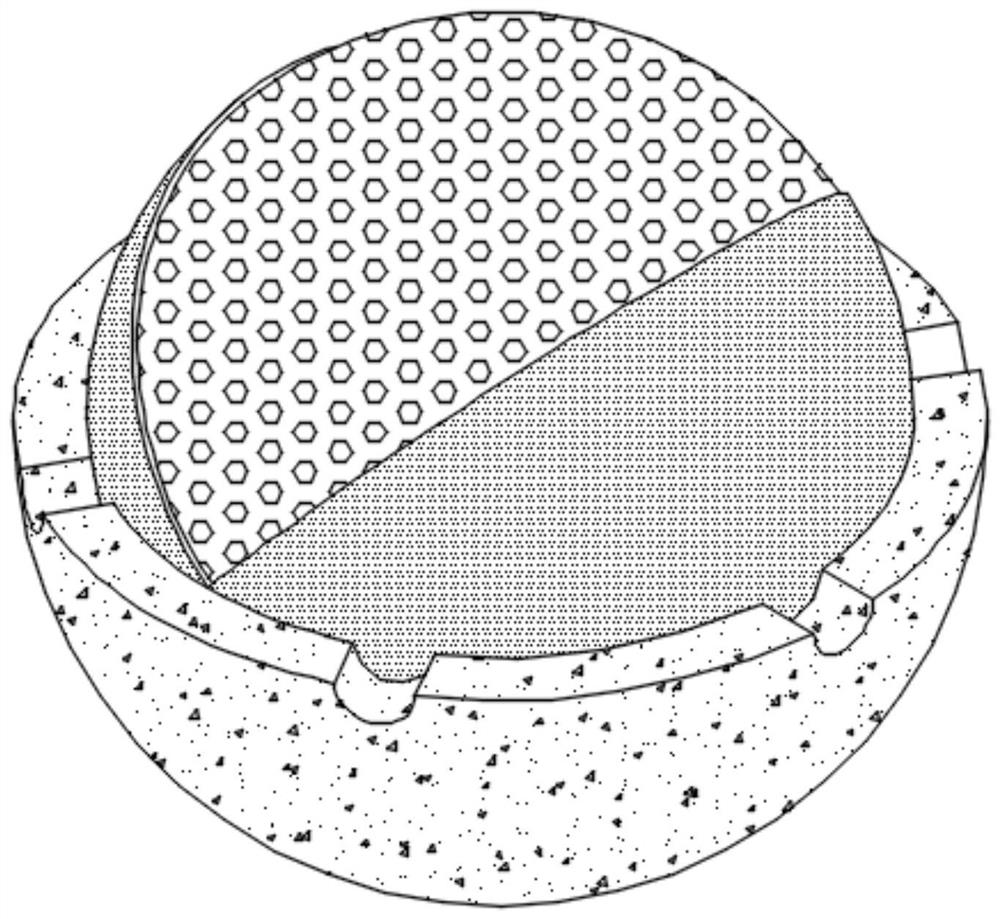

[0043] Embodiment 1: The components of the filler and the percentage by weight of each component are: 10% of dry sludge, 20% of clay, 12% of straw, 55% of ceramsite, and 5% of foaming agent; into silk, and the cross-sectional diameter of the straw silk is 1 mm, and the clay is ordinary clay. After the dry sludge, clay, shredded straw and foaming agent are stirred and mixed uniformly by a conventional mixing method, the mixed material Pour it into the existing mold, shape it into a spherical or rectangular shell, and form an internal cavity, and the formed shell is two halves that can be assembled into a spherical or rectangular splicing piece, and the ceramsite is wrapped with a degradable film. Then put the wrapped, sealed and wrapped ceramsite into the cavity inside the shell, and then form a complete spherical or rectangular shape with two splicing pieces and fix them into shape;

Embodiment 2

[0044] Embodiment 2: The components of the filler and the percentage by weight of each component are: 12% of dry sludge, 23% of clay, 17% of straw, 40% of ceramsite, and 8% of foaming agent; into silk, and the cross-sectional diameter of the straw silk is 3mm, and the clay is a mixture of red mud and ordinary clay. After the dry sludge, clay, shredded straw and foaming agent are stirred and mixed uniformly by a conventional mixing method, Pour the mixed material into the existing mold, shape it into a spherical or rectangular shell, and form an internal cavity, and the formed shell is two halves that can be assembled into a spherical or rectangular splicing piece. The ceramsite can be used Wrap it with a degradable film, then put the wrapped sealed and wrapped ceramsite into the cavity inside the shell, and then form a complete spherical or rectangular shape with two splicing pieces and fix it;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com