Intelligent logistics trolley carrying auxiliary device with reinforced fixing function

An auxiliary device and logistics technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of inconvenient use, need for human support, easy slipping, etc., to prevent accidental sliding and improve the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

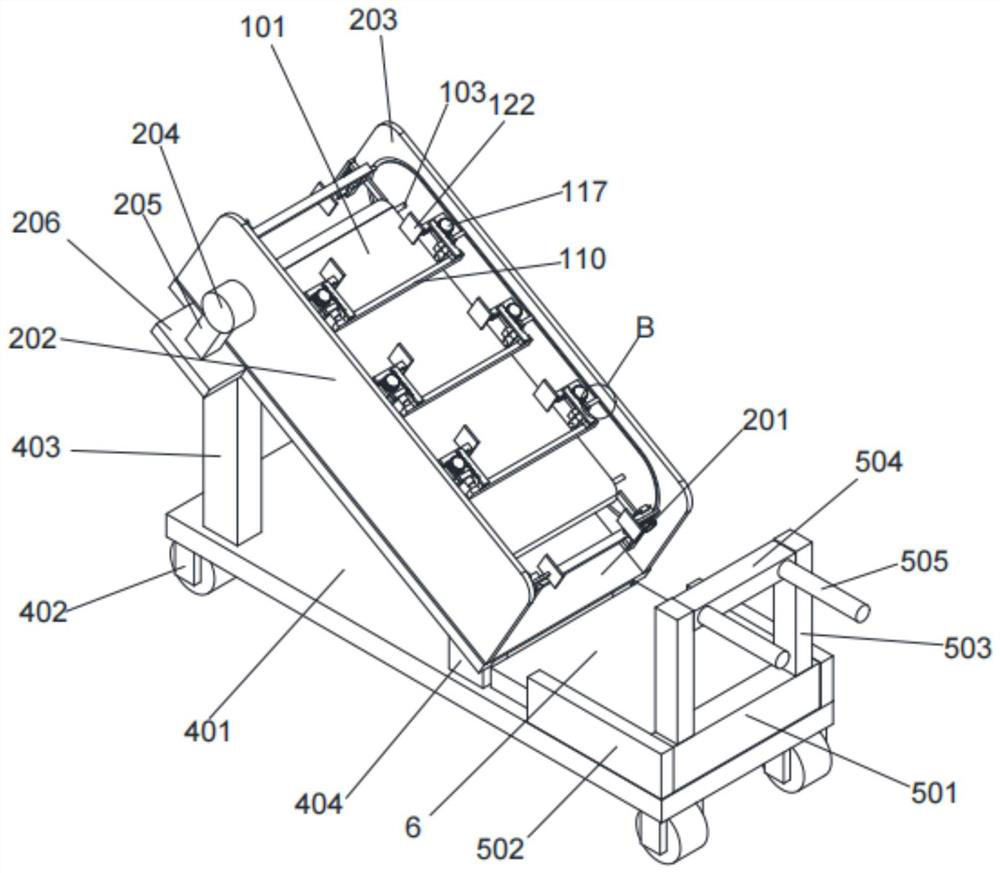

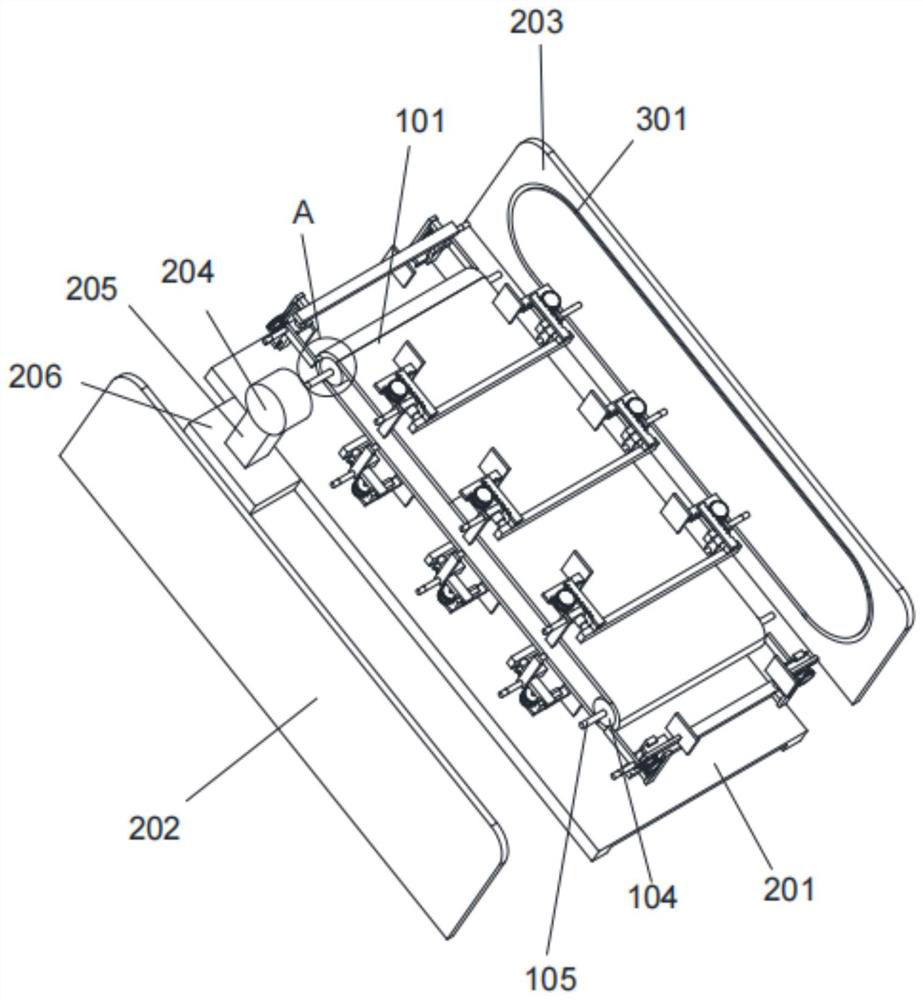

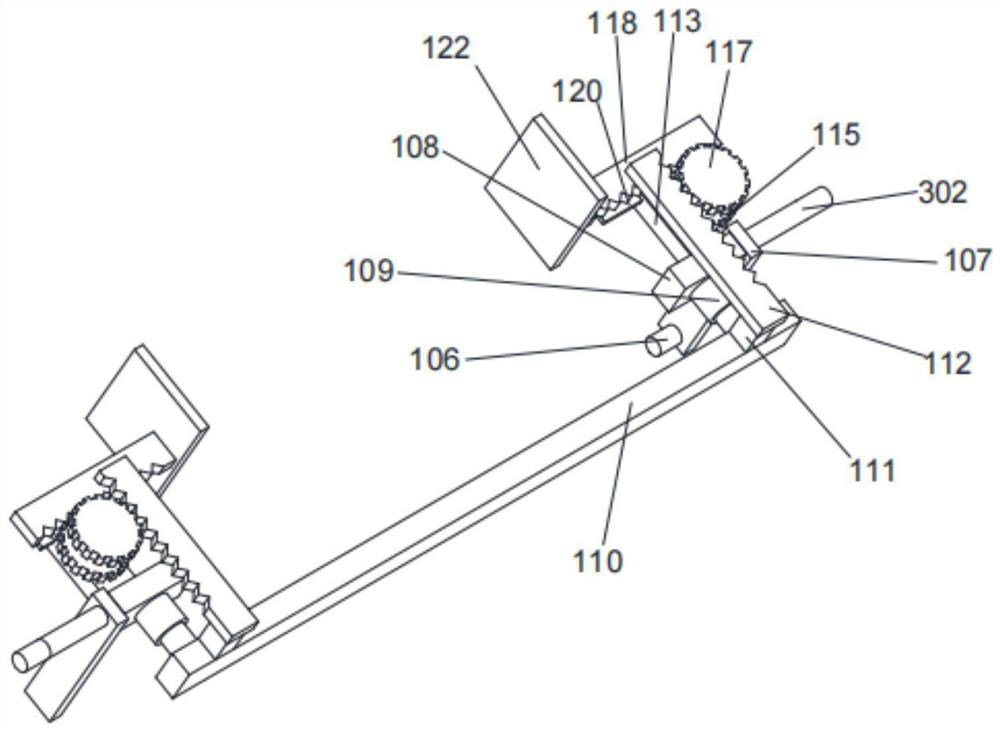

[0027] see Figure 1-Figure 6, the present invention provides a technical solution, including a transmission belt 101, the upper end of the inner wall of the transmission belt 101 is rotatably connected with a transmission roller 102, and the center of the left and right sides of the transmission roller 102 is fixedly connected with a support shaft 103, and the transmission belt 101 The lower end of the inner wall is rotatably connected with the transmission roller 2 104, the left and right sides of the transmission roller 104 are fixedly connected with the support shaft 2 105, the right side of the transmission belt 101 is fixedly connected with the connection shaft 106, and the right side of the connection shaft 106 is fixed. Connecting rod 107 is connected, and the upper end on the left side of connecting rod 107 is fixedly connected with connecting plate 108, and the front side of connecting plate 108 is fixedly connected with spring telescopic rod 109, and the front side o...

Embodiment 2

[0030] see figure 1 , On the basis of Embodiment 1, the present invention provides a technical solution: a base plate 401 is provided below the slant plate 201, self-locking wheels 402 are fixedly connected to the four corners of the lower surface of the base plate 401, and the rear end of the upper surface of the base plate 401 The first supporting leg 403 is fixedly connected, the upper surface of the bottom plate 401 is fixedly connected with the second supporting leg 404, the upper surfaces of the first supporting leg 403 and the second supporting leg 404 are fixedly connected to the lower surface of the inclined plate 201, and the front end of the upper surface of the bottom plate 401 is fixed A baffle plate 1 501 is connected, the left and right ends of the upper surface of the base plate 401 are fixedly connected with a baffle plate 2 502, the left and right sides of the baffle plate 501 are fixedly connected with the sides of the baffle plate 2 502, and the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com