A 3D printing extrusion nozzle based on the field of industrial design

A 3D printing and nozzle technology, applied in the direction of additive processing, coating devices, etc., can solve the problems of printing model failure, poor sealing effect of joints, residual materials, etc., and achieve the effect of strengthening the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

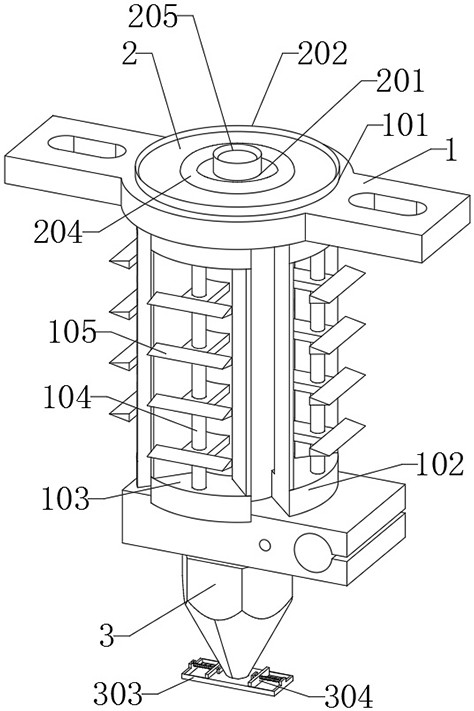

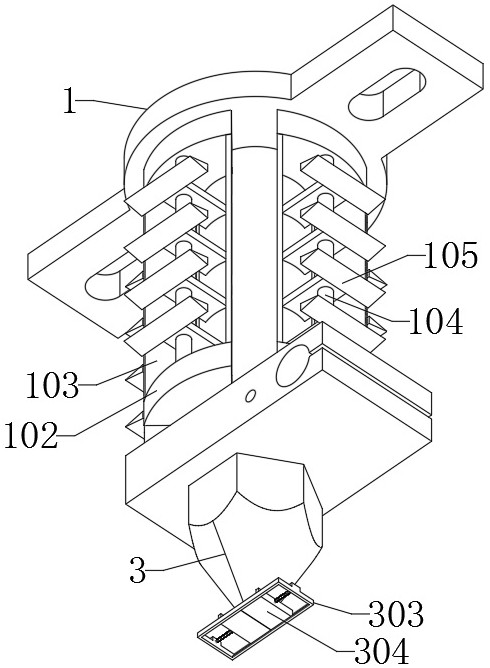

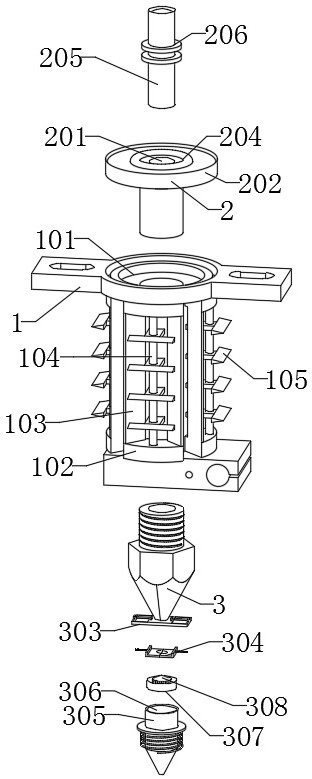

[0058] as attached figure 1 to attach Figure 8 Shown:

[0059] The present invention provides a 3D printing extrusion nozzle based on the field of industrial design, including a main body 1; the main body 1 is the body of the 3D printing extrusion nozzle, and the inside of the main body 1 is a cylindrical structure, and the top of the main body 1 is installed with a seal 2, The bottom of the main body 1 is equipped with a bottom head 3 through a threaded hole; the seal 2, the seal 2 includes an isolation mechanism, and the interior of the seal 2 is equipped with an isolation mechanism, the seal 2 is made of rubber, and the seal 2 is a raised one in the middle. Cylindrical structure; the bottom head 3, the bottom of the bottom head 3 is a tapered structure, and the top outside of the bottom head 3 is provided with threads.

[0060] like Figure 4 As shown, wherein, the main body 1 includes: a top groove 101, the top groove 101 is a cylindrical structure protruding in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com