Welded blade of rotary shaver

A razor, rotary technology, applied in the field of welding blades, can solve the problems of low performance requirements of grinding equipment, shaving of high hardness materials, low operation requirements, etc., to improve market competitiveness, strong wear resistance, reduce Effect of Welding Times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

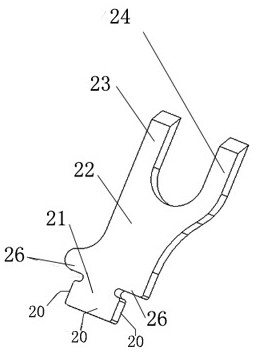

[0025] Embodiment 1: as Figure 1-3 As shown, the welded blade of the rotary shaver includes a blade base 1 and a cutter ring arranged on the blade base 1. The cutter ring includes a plurality of rotating blades distributed around the central axis of the blade base 1 The cutter 2, the cutter 2 is welded to the blade base 1, and the cutter 2 is connected to the blade base 1 by welding, which not only solves the problem that the high hardness material cannot be used as the cutter material for shaving in the prior art, The obtained cutter 2 has good cutting edge retention, strong wear resistance, and long service life. Moreover, the cutter 2 can be polished independently without interference or influence of other parts except the cutter 2. Therefore, the grinding equipment The performance requirements are low, and the operation requirements for workers are low; the blade base 1 is provided with an attachment base surface 11, and the cutter 2 is provided with an attachment surface...

Embodiment 2

[0030] Embodiment 2: as Figure 4 As shown, the welded blade of the rotary shaver includes a blade base 1 and a cutter ring arranged on the blade base 1. The cutter ring includes a plurality of rotating blades distributed around the central axis of the blade base 1 The cutter 2, the cutter 2 is welded to the blade base 1, and the cutter 2 is connected to the blade base 1 by welding, which not only solves the problem that the high hardness material cannot be used as the cutter material for shaving in the prior art, The obtained cutter 2 has good cutting edge retention, strong wear resistance, and long service life. Moreover, the cutter 2 can be polished independently without interference or influence of other parts except the cutter 2. Therefore, the grinding equipment The performance requirements are lower, and the operation requirements for workers are lower.

[0031] The blade base 1 is provided with an attachment base surface 11, and the cutter 2 is provided with an attachme...

Embodiment 3

[0033] Embodiment 3: see Figure 5 As shown, the welded blade of the rotary shaver includes a blade base 1 and a cutter ring arranged on the blade base 1. The cutter ring includes a plurality of rotating blades distributed around the central axis of the blade base 1 The cutter 2, the cutter 2 is welded to the blade base 1, and the cutter 2 is connected to the blade base 1 by welding, which not only solves the problem that the high hardness material cannot be used as the cutter material for shaving in the prior art, The obtained cutter 2 has good cutting edge retention, strong wear resistance, and long service life. Moreover, the cutter 2 can be polished independently without interference or influence of other parts except the cutter 2. Therefore, the grinding equipment The performance requirements are lower, and the operation requirements for workers are lower.

[0034] The blade base 1 is provided with an attachment base surface 11, and the cutter 2 is provided with an attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com