New energy automobile oil way pipe fitting connector rapid manufacturing production process

A new energy vehicle and production process technology, applied in the field of pipe fittings manufacturing, can solve problems such as the inability to reduce manpower operations, inability to guide and throttle parts, and the impact of employee production speed, so as to reduce manpower cleaning and salvage, reduce manual transportation and The effect of handling, convenient and uniform transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

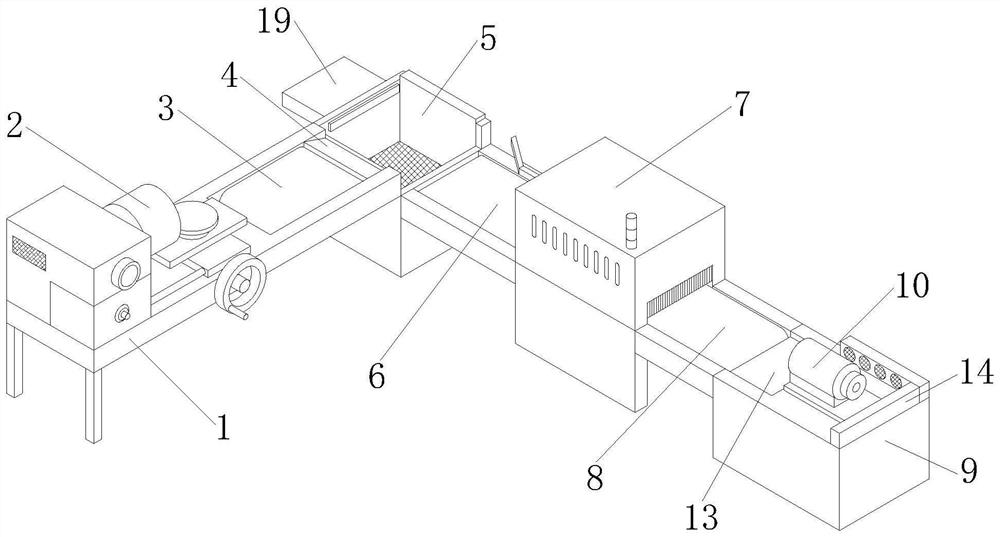

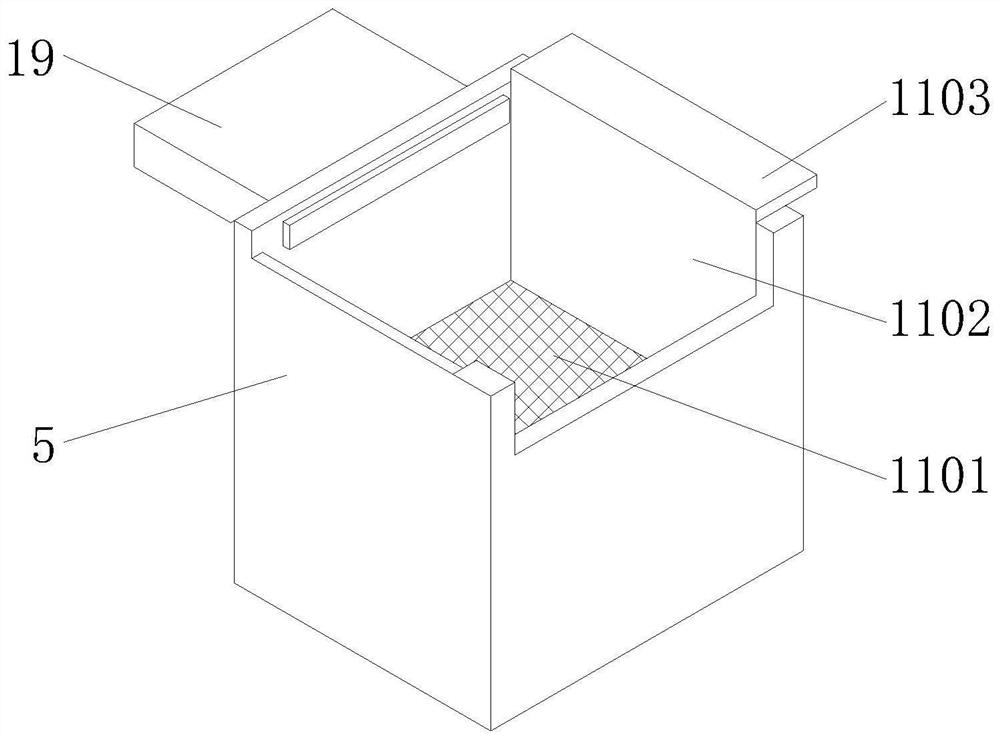

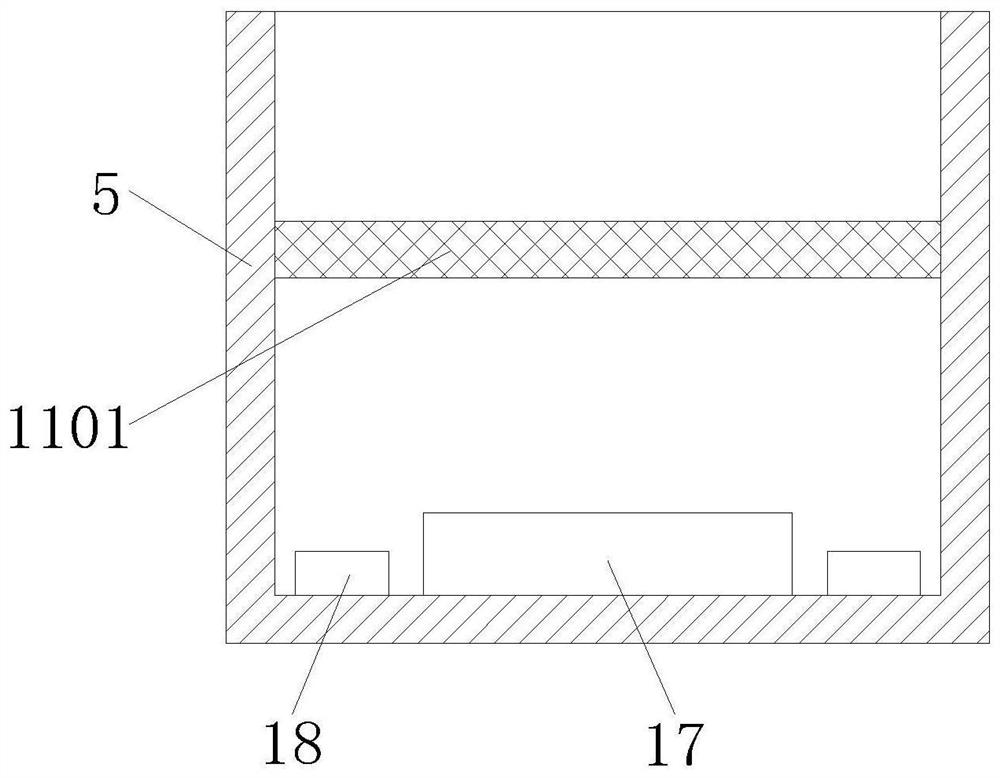

[0045] Such as Figure 1-11 As shown, a new energy vehicle oil pipe joint rapid manufacturing production process includes a first console 1, the top of the first console 1 is provided with a cutting device 2, and the inner cavity of the first console 1 is movably connected with a second A conveyor belt 3, the right side of the first operating table 1 is provided with a chute 4, the right side of the first operating table 1 is provided with a cleaning pool 5, and the front side of the cleaning pool 5 is movably connected with a second conveyor belt 6, and the second conveyor belt 6 The front side of the drying device 7 is provided with a drying device 7, the front side of the drying device 7 is movably connected with a third conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com