Flue gas distributor device with automatic ash removal function

An automatic dust removal and distributor technology, applied in the field of environmental engineering, can solve the problems of increasing the flue gas flow rate, poor flue gas diffusion effect, no explanation or report found, etc., to achieve the effect of preventing blockage, good effect, and preventing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

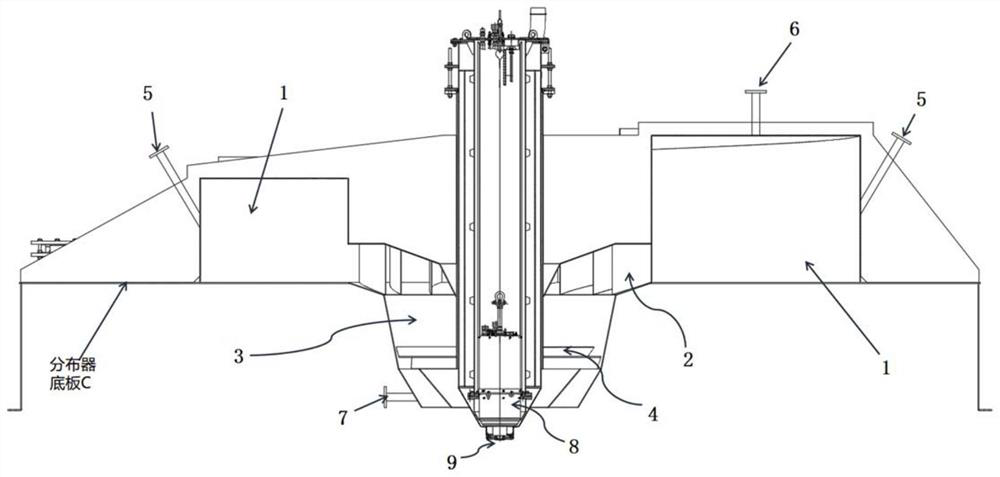

[0046] figure 1 It is a schematic structural diagram of a smoke distributor device with an automatic dust cleaning function provided by an embodiment of the present invention.

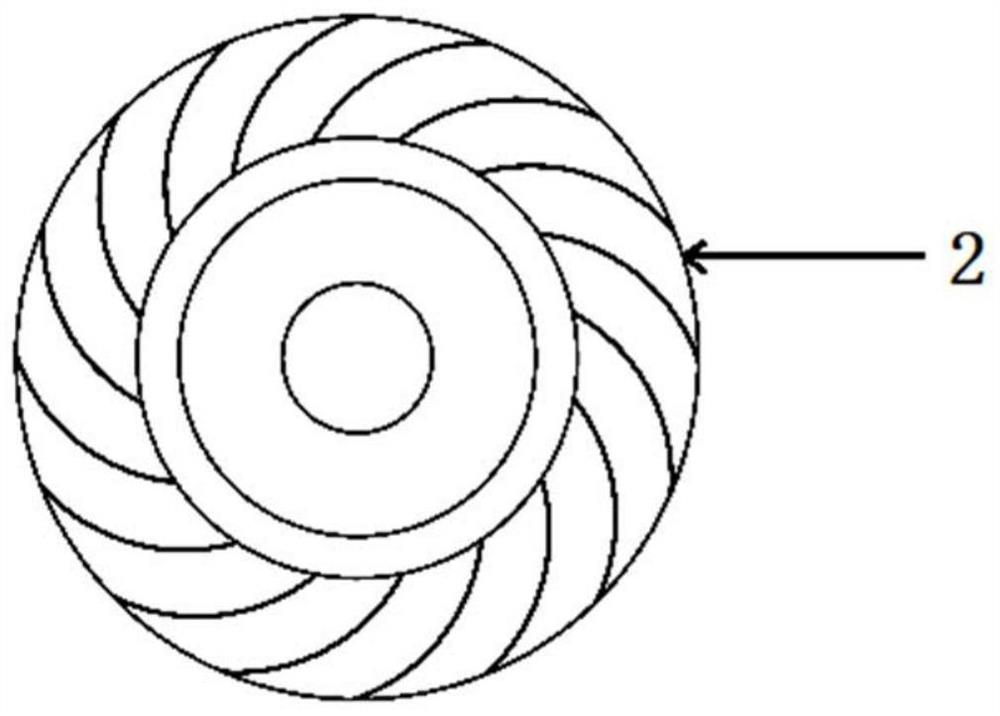

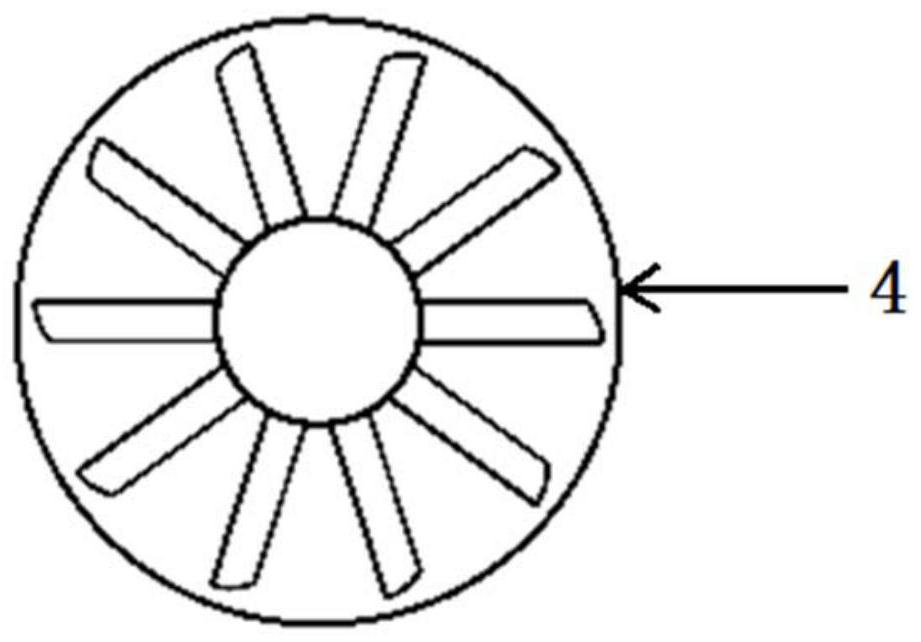

[0047] Such as figure 1 As shown, the smoke distributor device with automatic dust removal function provided by this embodiment may include: a smoke inlet flue 1, a first layer of guide vanes 2 arranged inside the smoke inlet flue 1, and a first layer of The flue gas vertical channel 3 connected to the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com