Viscous food material processor and method

A processing method and processing machine technology, which is applied to kitchen utensils, household utensils, utensils with integral electric heating devices, etc., can solve the problems of viscous food materials being damaged and unable to meet the cooking requirements of viscous food materials, achieve beautiful appearance and reduce stirring workload , The effect of color, fragrance and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

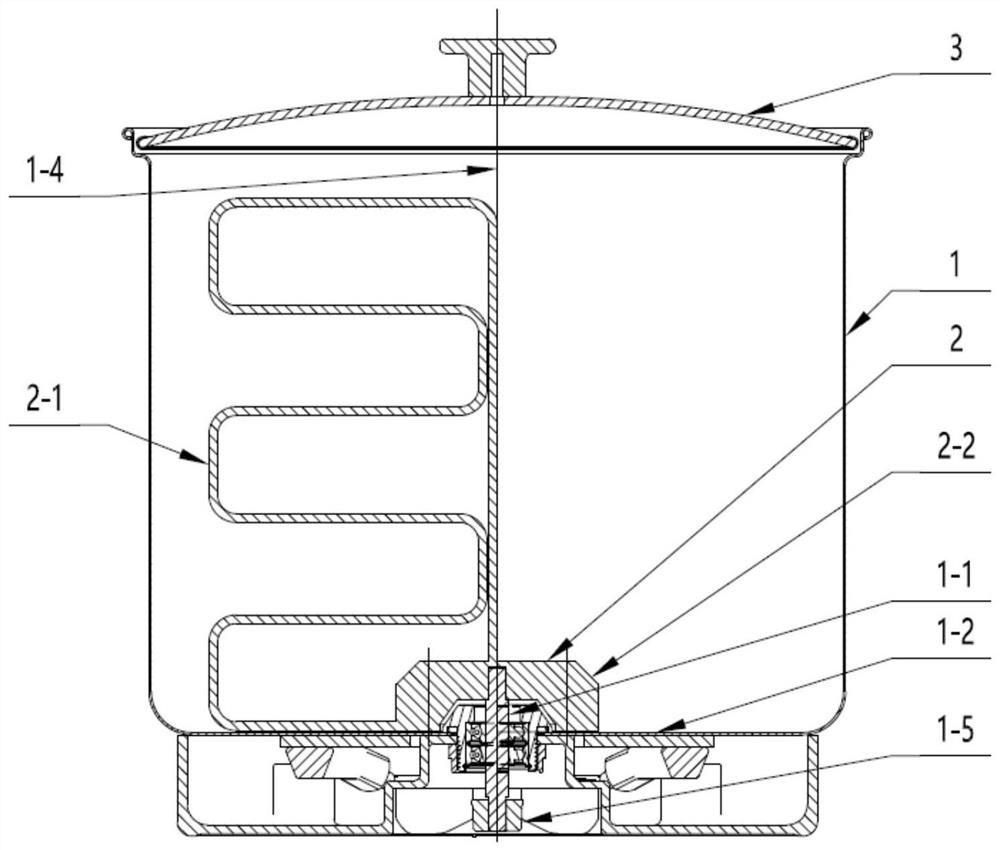

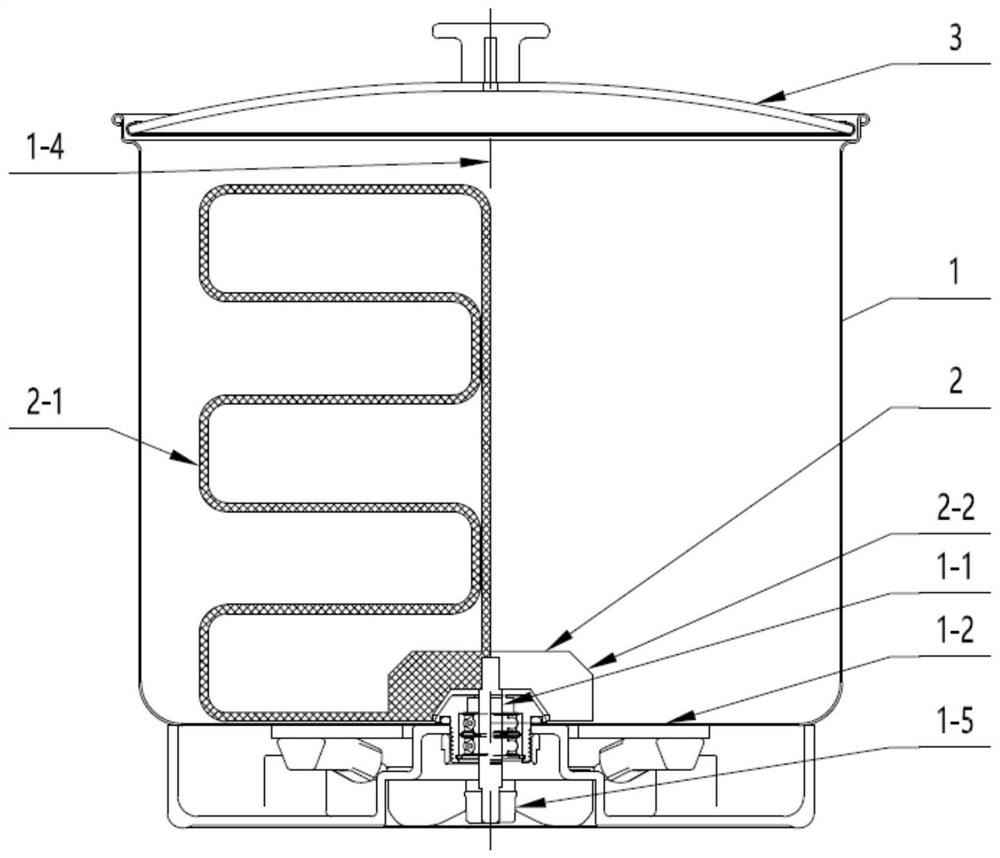

[0091] A specific embodiment of the present invention discloses a viscous food processing machine, such as Figure 1-8 As shown, the sticky food processor includes:

[0092] a container 1 comprising a chamber to contain a viscous food material and a soaking liquid;

[0093] The stirring paddle 2 is pivotally arranged in the container 1; the stirring paddle 2 is provided with a hollow structure to allow food particles to pass through the hollow structure;

[0094] A motor, connected to the stirring paddle 2, drives the stirring paddle 2 to rotate in the container 1;

[0095] a heater for heating the contents of the container 1;

[0096] A controller, the controller is connected with the motor, controls the motor to drive the stirring paddle 2 to rotate at a first speed, and the first speed is 5 to 300 rpm; and the controller and the heater connected, the heater is controlled to heat at the first power before adding the viscous food into the container 1, and to heat with the ...

Embodiment 2

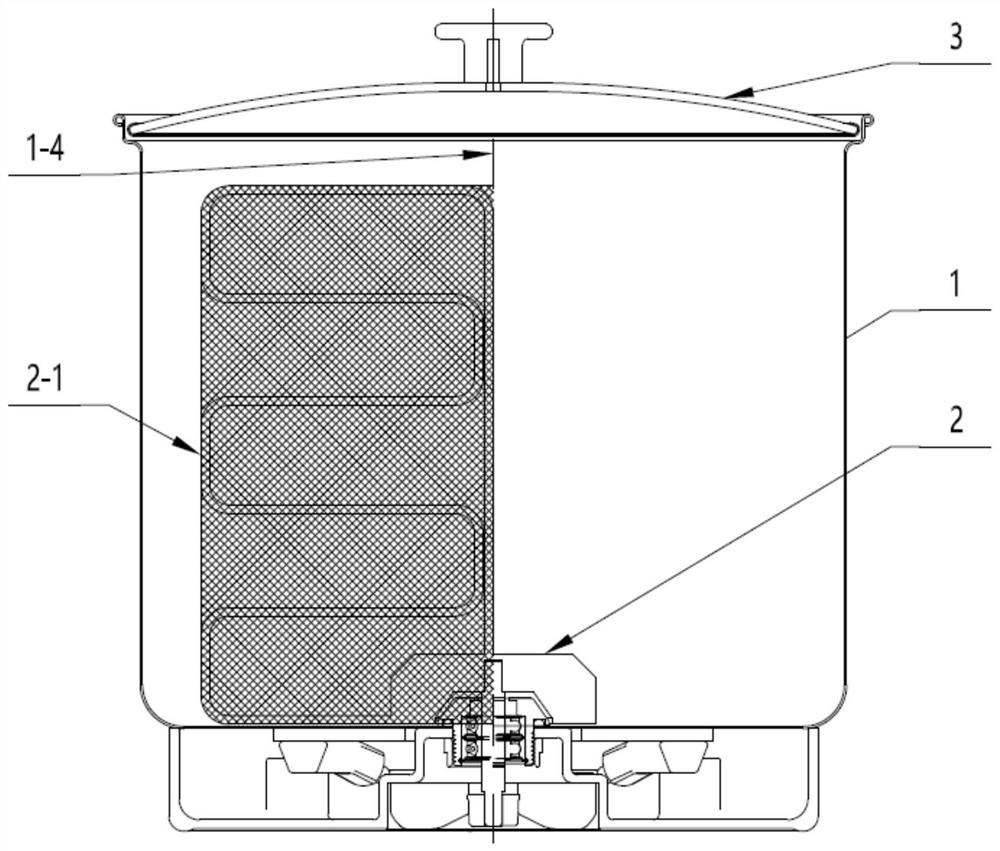

[0124] Another specific embodiment of this embodiment discloses a viscous food material processor, the stirring paddle 2 provided in the container 1 of the processor has the following structural features:

[0125] The actual area of the longitudinal section of the stirring paddle 2 is S1, the occupied area of the longitudinal section of the stirring paddle 2 is S2, the half area of the longitudinal stirring working section of the container 1 is S3, and the S1, S2, S3 have the following relationship:

[0126] 0.01≤S1 / S2≤0.3, 0.5≤S2 / S3<1.

[0127] Wherein, the actual area S1 of the longitudinal section of the stirring paddle 2 refers to the projected area of the stirring paddle 2 in the vertical plane, such as figure 2 shown. The projection of the stirring paddle 2 in the vertical plane has the two ends of the highest end, the lowest end and the outermost. The cross-sectional area enclosed by the horizontal line, the lowest horizontal line and the outermost vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com