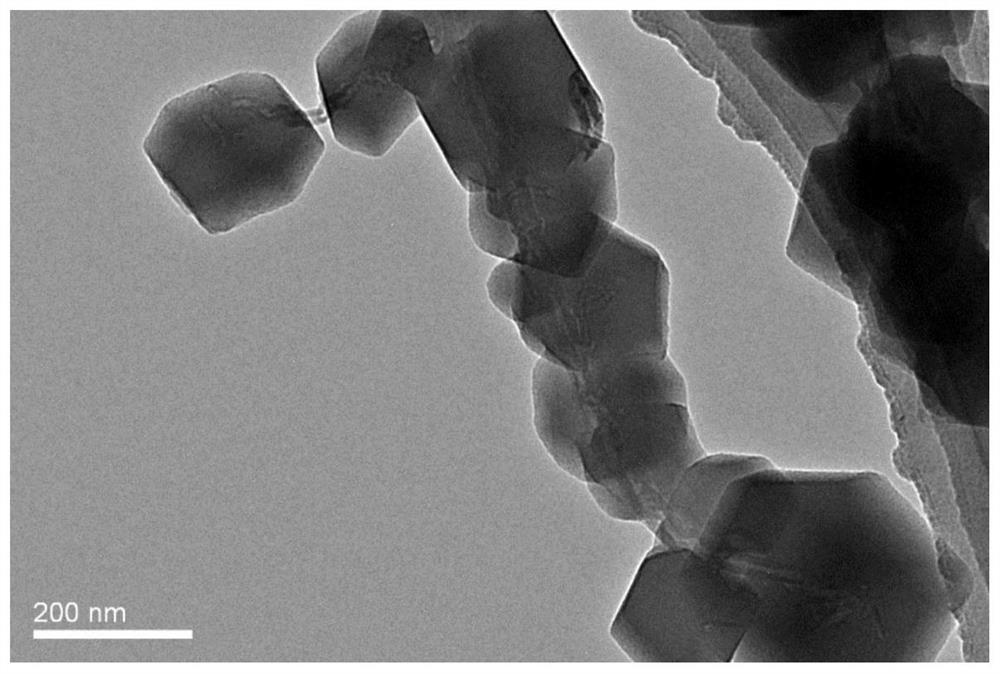

Carbon nanotube string carbon hollow polyhedral nanosphere material as well as preparation and application thereof

A technology of carbon nanotubes and polyhedrons, which is applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of large contact resistance and loose contact, achieve short embedding paths, increase electrical conductivity, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 720mg Zn(NO 3 ) 2 ·6H 2 O was dissolved in 20 mL of methanol and stirred for 10 min as solution 1; 1950 mg of dimethylimidazole and 40 mg of acidified carbon nanotubes were dissolved in 20 mL of methanol, and the solution was sonicated 4 times for 5 min each as solution 2. Quickly pour solution 1 into solution 2, stir for 5 minutes to form a mixed solution; transfer the mixed solution to a 100mL Teflon autoclave, put the Teflon autoclave in a 90°C oven for 6 hours, and after natural cooling, wash it with methanol for three The product was collected by centrifugation, and the obtained product was dried in an oven at 60° C. to obtain ZIF-8@carbon nanotubes.

[0028] (2) Disperse 500mg of ZIF-8@carbon nanotubes in 250mL of ethanol, sonicate for 15min to form a uniform mixed solution, as solution 3; dissolve 500mg of tannic acid in 250mL of deionized water, stir for 15min to form a uniform mixture Solution, as solution 4: quickly pour solution 4 into solution 3, stir...

Embodiment 2

[0034] (1) 720mg Zn(NO 3 )·6H 2 O was dissolved in 20 mL of methanol and stirred for 10 min as solution 1; 1950 mg of dimethylimidazole and 40 mg of acidified carbon nanotubes were dissolved in 20 mL of methanol, and the solution was sonicated 4 times for 5 min each as solution 2. Quickly pour solution 1 into solution 2, stir for 5 minutes to form a mixed solution; transfer the mixed solution to a 100mL Teflon autoclave, put the Teflon autoclave in a 90°C oven for 6 hours, and after natural cooling, wash it with methanol for three The product was collected by centrifugation, and the obtained product was dried in an oven at 60° C. to obtain ZIF-8@carbon nanotubes.

[0035] (2) Disperse 500mg of ZIF-8@carbon nanotubes in 250mL of ethanol, sonicate for 15min to form a uniform mixed solution, as solution 3; dissolve 750mg of tannic acid in 250mL of deionized water, stir for 15min to form a uniform mixture Solution, as solution 4: quickly pour solution 4 into solution 3, stir for...

Embodiment 3

[0039] (1) 936mg Zn(NO 3 )·6H 2 O was dissolved in 20 mL of methanol and stirred for 10 min as solution 1; 2535 mg of dimethylimidazole and 40 mg of acidified carbon nanotubes were dissolved in 20 mL of methanol, and the solution was sonicated 4 times for 5 min each as solution 2. Quickly pour solution 1 into solution 2, stir for 5 minutes to form a mixed solution; transfer the mixed solution to a 100mL Teflon autoclave, put the Teflon autoclave in a 90°C oven for 6 hours, and after natural cooling, wash it with methanol for three The product was collected by centrifugation, and the obtained product was dried in an oven at 60° C. to obtain ZIF-8@carbon nanotubes.

[0040] Subsequent steps are the same as in Example 1.

[0041] The structure of the product carbon nanotube string carbon hollow polyhedral nanosphere material is similar to that of Example 1, the main difference being that the size of the carbon hollow polyhedral nanosphere increases to about 250 nm.

[0042] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com