Small pile foundation vibration resistance reduction type efficient pile pulling device for hydraulic engineering construction

A technology for water conservancy projects and small piles, which is applied in infrastructure engineering, sheet pile walls, buildings, etc. It can solve the problems of reducing pile pulling efficiency, easily damaged equipment, and large frictional resistance, so as to improve pile pulling efficiency and reduce usage scenarios , the effect of friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

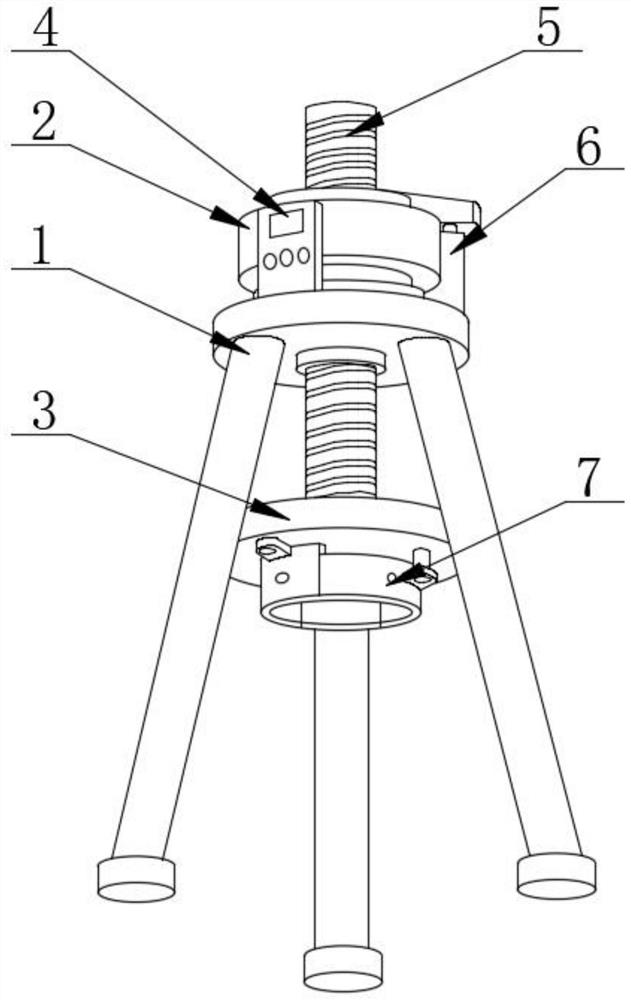

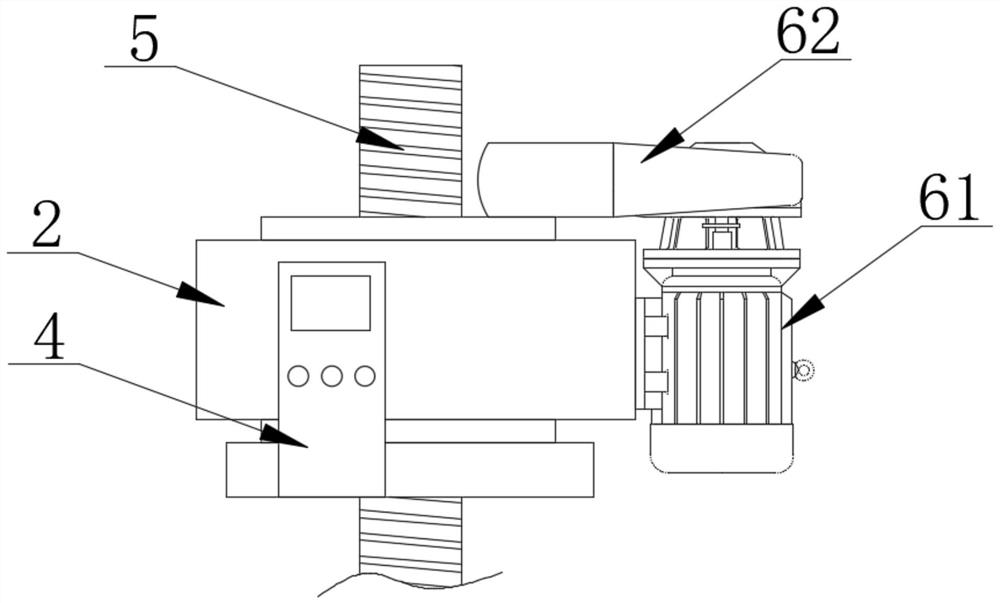

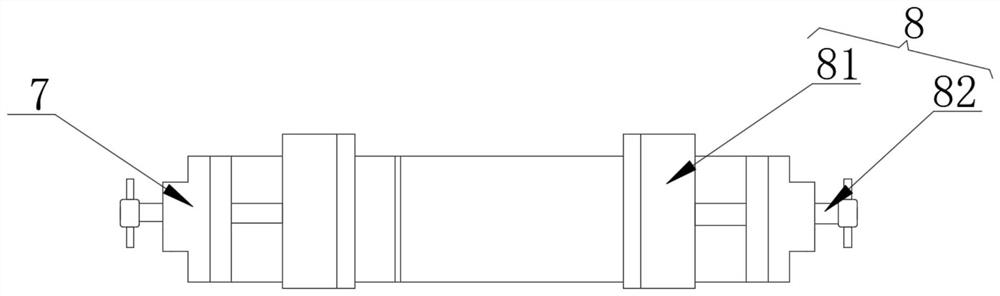

[0032] Append figure 1 Adherent Figure 8Embodiments of the present invention provides a highly efficient hydraulic engineering construction equipment small pile pulling pile vibration drag type, comprising a support stand 1, pulling the pile driving mechanism 2 and a drive mechanism 6, pulling the pile driving mechanism 2 is fixed by a screw attached to the stand supporting a top surface, a driving mechanism 6 is fixedly mounted to the side of the support stand 1, the surface of the pulling pile driving mechanism 2 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com