Method for rapidly repairing defects of concrete pavement

A technology for concrete pavement and concrete surface, applied in road repair, roads, roads, etc., can solve the problems of difficult quality assurance and low efficiency, and achieve the effect of ensuring preparation efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

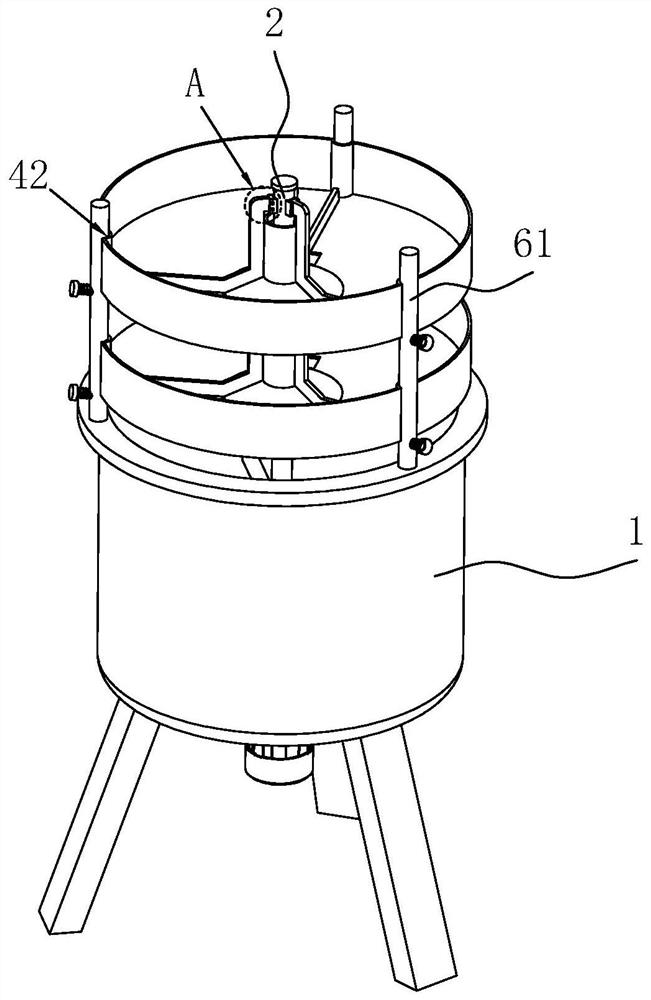

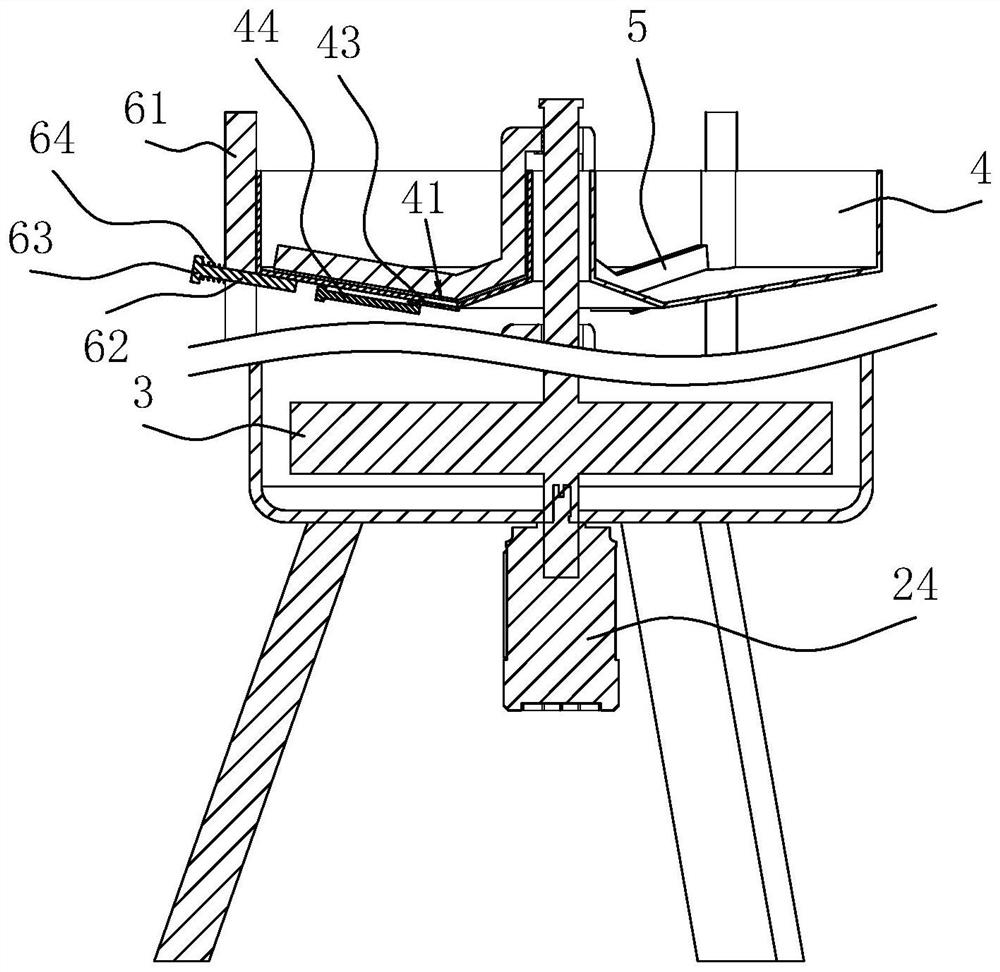

[0043] The following is attached Figure 1-4 The application is described in further detail.

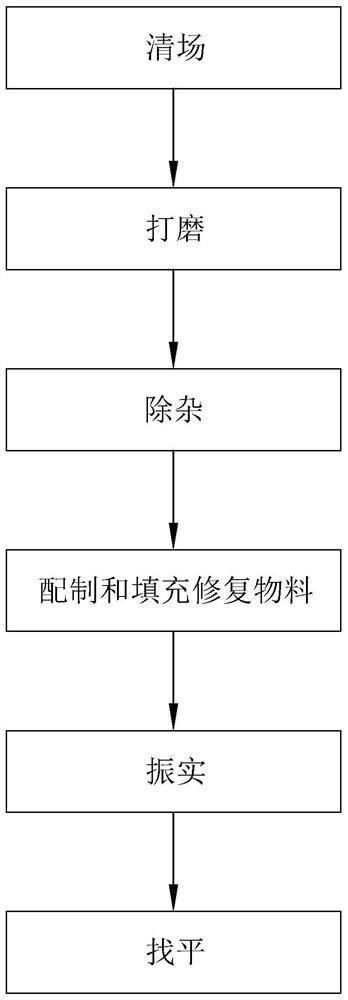

[0044] The embodiment of the present application discloses a method for quickly repairing concrete pavement defects. refer to figure 1 , the method for rapid repair of concrete pavement defects is used for repairing potholes in concrete pavement, comprising the following steps:

[0045] S1. Clear the broken and loose concrete blocks at the potholes or expansion joints out of the site;

[0046] S2. Grinding the concrete surface of the repaired part with a grinder until it is 3-4mm lower than the concrete surface outside the pit;

[0047] S3. Remove the soil and dirt on the surface of the concrete in the repair area to ensure that the repair work surface is dry;

[0048] S4. Prepare epoxy asphalt cement or epoxy asphalt mortar, and pour the prepared epoxy asphalt cement or epoxy asphalt mortar into the pothole to be repaired;

[0049] S5. Tap the filler with a rubber hammer until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com