Preparation method of Ni(OH)2/graphene composite material and preparation method of supercapacitor

A technology of supercapacitors and composite materials, applied in the direction of hybrid capacitor electrodes, graphene, chemical instruments and methods, etc., can solve the problems of lack of dangling bonds and defect sites, poor conductivity of graphite oxide, etc., to increase uniformity and binding ability , Improve energy density, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Ni (OH) of the present invention, one kind of 2 / Graphene producing a composite material, comprising the steps of:

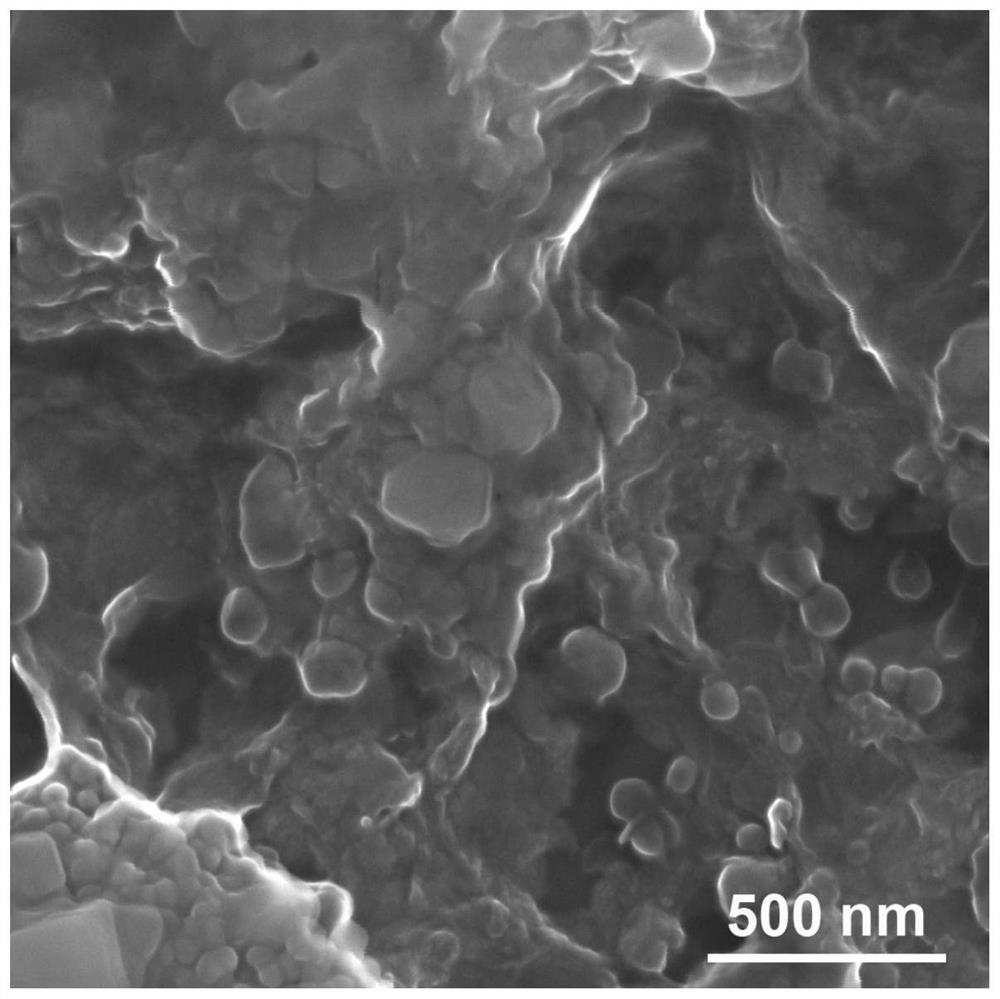

[0042] Preparation of (1) a porous graphene oxide (HGO) solution: 5mL concentration of 30% H 2 O 2 Aqueous solution 50mL 2mg / mL solution of graphene oxide (GO) are mixed and then magnetically stirred under heating at 95 deg.] C reaction 4h. After completion of the reaction, the centrifuge (rotational speed: 12000r / min, Time: 10min) and washed twice to remove remaining mixture H 2 O 2 To achieve the purpose of purifying porous graphene oxide, the graphene oxide porous purified (HGO), HGO was then dispersed in 50mL of deionized water, and ultrasonic dispersion, a concentration of 2mg / mL HGO uniform dispersion;

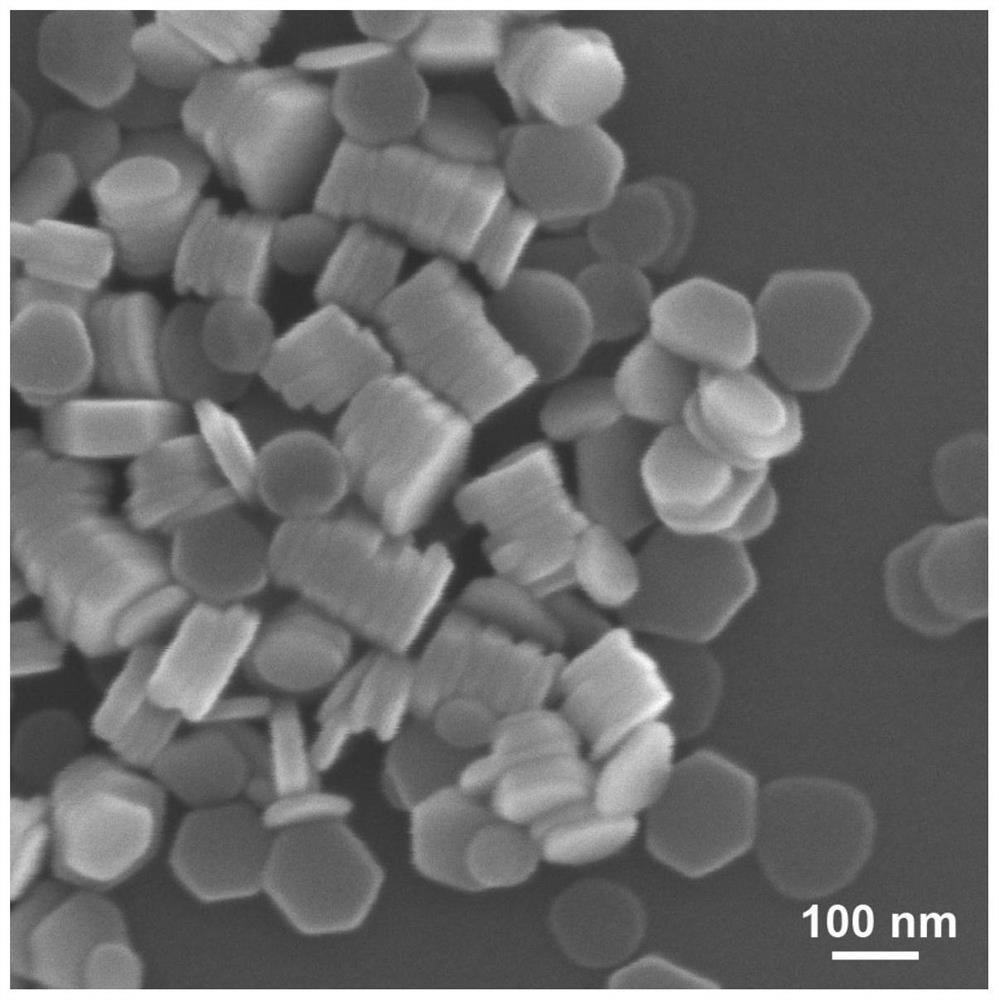

[0043] (2) Ni (OH) 2 / -En Composite Graphite: the step of taking 12.5mL HGO dispersion (1) prepared was dissolved in 50ml of DMF, and added to a round bottom flask, the mixture was heated with stirring (magnetic stirrer) to 80 ℃, the was added 5m...

Embodiment 2

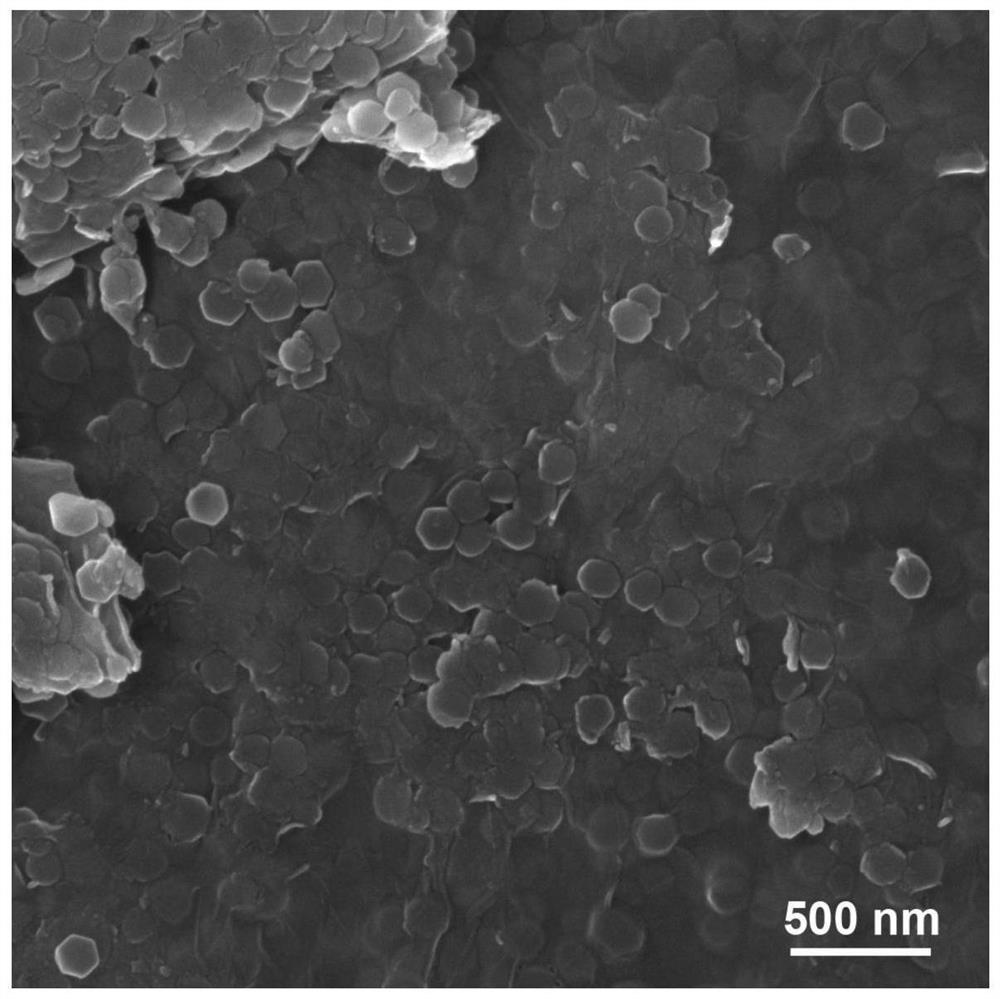

[0056] Ni (OH) prepared in Example 1 of the present embodiment to embodiment 2 / HGO based composite flexible printed super capacitor device, particularly the preparation process is as follows:

[0057] (1) Ni (OH) 2 Preparation / HGO Composites: same method of Preparation Example 1;

[0058] (2) Ni (OH) 2 / HGO ink prepared: a mass ratio of 7.5: 1.5: 1 ratio 0.134g Ni (OH) 2 / HGO composite powder, 0.0268 g of acetylene black, 0.357 g of 5% strength aqueous binder LA133 and add an appropriate amount of water, formulated to a viscosity of 0.2Pa · s for screen printing Ni (OH) 2 / HGO ink;

[0059] (3) Preparation of a printed super capacitor: Ni prepared by the 200-mesh screen plate silver nanoparticle paste, the step (2) (OH) 2 / HGO ink, PVA basic successively superimposed solid electrolyte printed on PET, made of a super capacitor patterns (1x1cm 2 Solid pattern), then the product obtained by the screen printing oven dried 10min at 70 ℃, forming a flexible supercapacitor device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com