Material storage bin

A technology for storage bins and materials, applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve the problems of large blocks, high hardness, and low moisture content of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

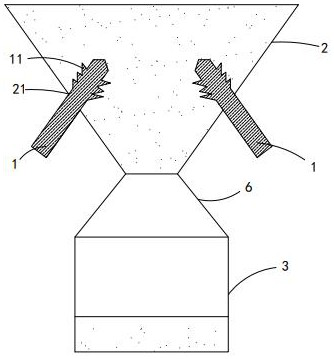

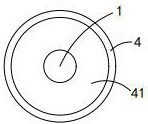

[0027] see Figure 1-3 , this embodiment provides a material storage bin, including a drive assembly, a frame (not shown in the figure), an electric heating rod 1, a feeding funnel 2 and a collection basin 3,

[0028] The feeding funnel 2 and the collecting basin 3 are all installed on the frame, and the collecting basin 3 is located below the discharging funnel 2, and the material is transported to the collecting basin 3 through the discharging funnel 2 under the action of gravity, so the discharging funnel 2 It is the necessary road section in the process of conveying materials to the collection basin 3 .

[0029] The side wall of the feeding funnel 2 is provided with an active hole 21 that matches the shape of the electric heating rod 1. The electric heating rod 1 is plugged into the active hole 21, and the driving component is transmitted to the electric heating rod 1, thereby controlling the electric heating rod 1 to move in the active hole 21. Move, so that the electric...

Embodiment 2

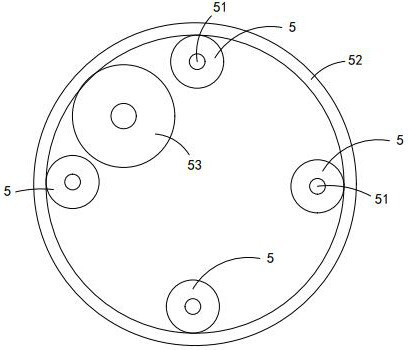

[0049] The difference between this embodiment and Embodiment 1 is that the material storage bin also includes a beating assembly, the beating assembly is installed on the frame and is located below the feeding funnel 2, and the beating assembly is carried out on the bottom outer wall of the feeding funnel 2. Beating, so that the fragmented material can enter the collection basin more smoothly.

[0050] The beating assembly includes a rotating ring 7 , a beating rod 72 and a return spring 73 .

[0051] The top of the rotating ring 7 protrudes upwards to form an annular wave-shaped projection 71, and the rotating ring 7 is also rotatably mounted on the frame. Specifically, the frame can be provided with a second annular slide rail 74 below the rotating ring 7 through a connecting rod, and the bottom of the rotating ring 7 protrudes downward to form an annular slider, which is arranged on the second annular slide In the rail 74, the rotation process of the rotating ring 7 is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com