Electromagnetic-triggered pressing and releasing device and using method

A release device and electromagnetic triggering technology, applied in the aerospace field, can solve the problems of short actuation time, impact load, potential safety hazards that can only be used once, large impact load, etc., and achieve reliable locking method, space and weight saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those of ordinary skill in the art to which the invention pertains can easily realize these embodiments, but the present invention can also be realized in various forms, The present invention is therefore not limited to the embodiments described hereinafter.

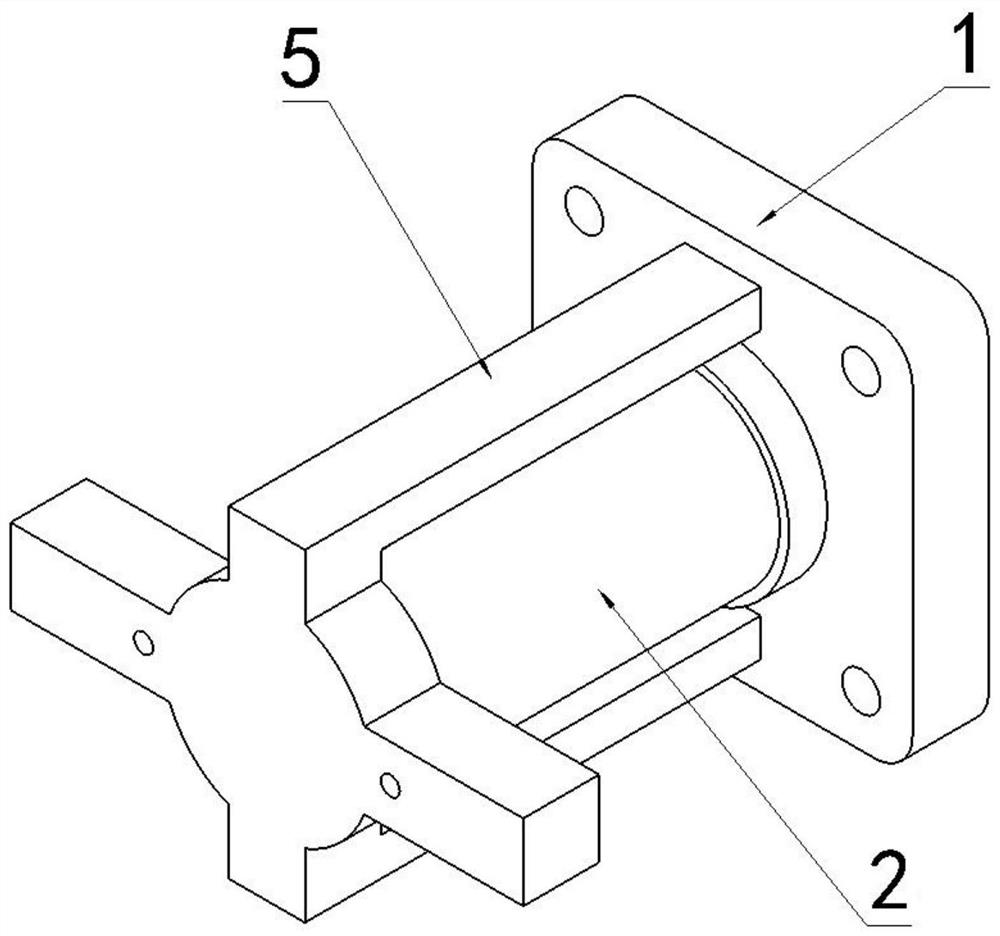

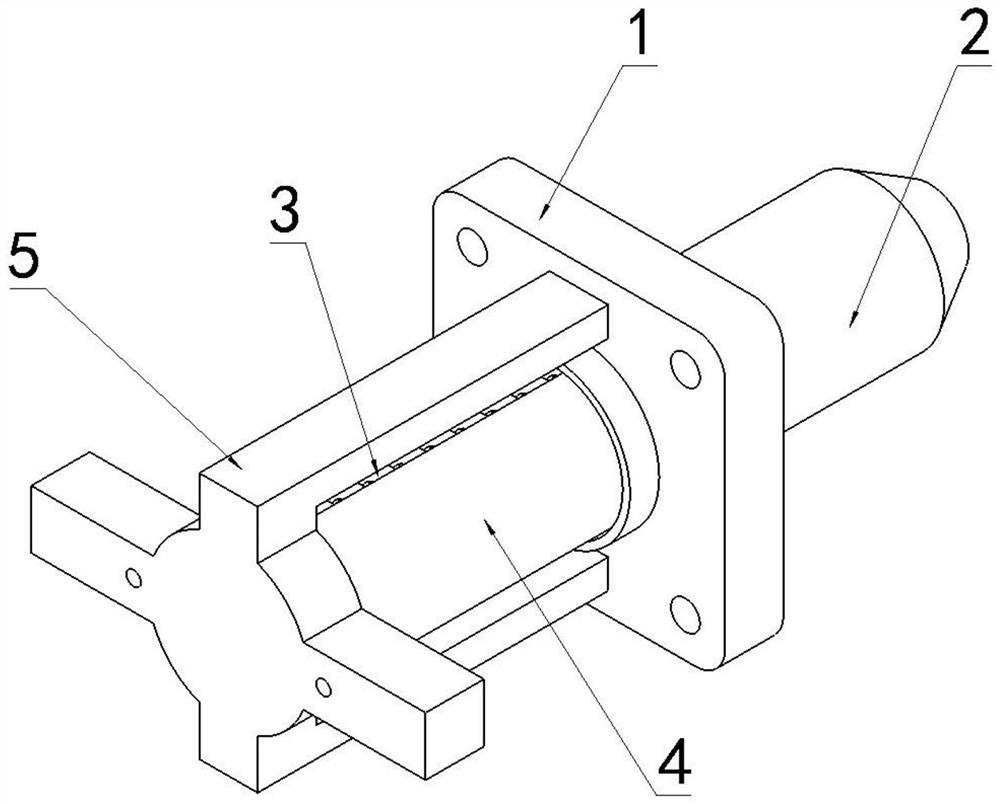

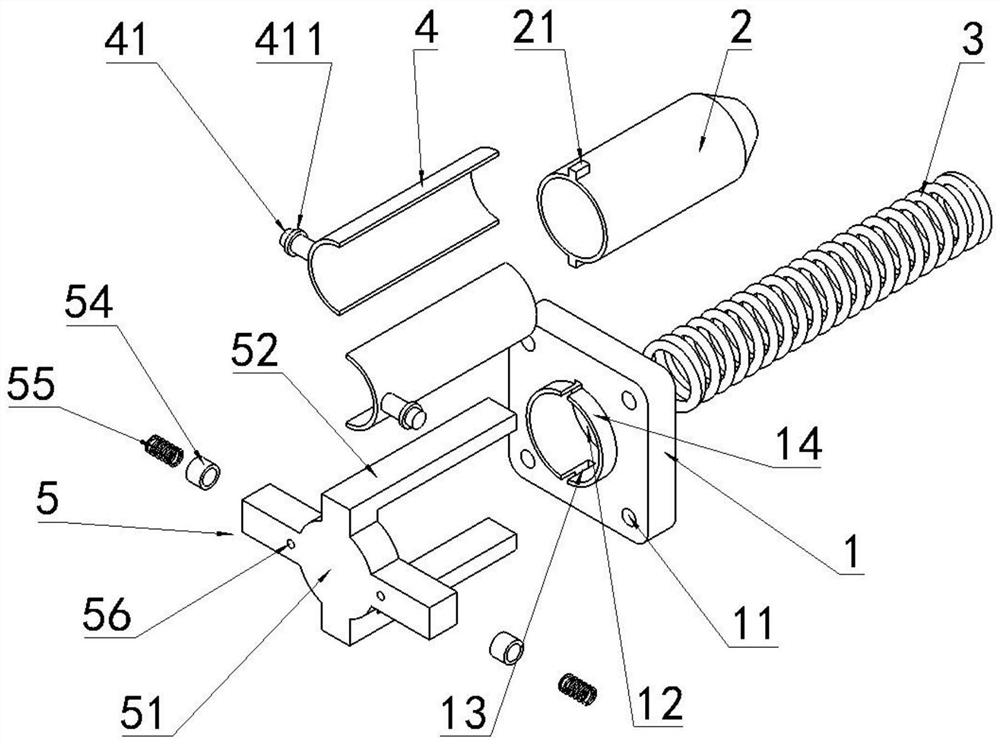

[0027] Such as figure 1 , 2 As shown, an electromagnetically triggered compression release device includes: a support 1, a pin shaft 2, a spring 3, a spring retaining ring 4, and a limiting element 5;

[0028] The support 1 is fixedly connected with the outer part, the inside of the pin shaft 2 is a hollow structure and the pin shaft 2 passes through the pin shaft hole 12 and is inserted into the outer part when it is in a compressed state, and the spring one 3 is arranged on the retaining ring 4 and the pin shaft 2 Inside, the left and right ends are fixedly connected with the pin shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com