Automatic hot melting nut jig

A hot-melt and nut technology, applied in the field of automatic hot-melt nut fixtures, can solve problems such as failure to meet usage requirements, nut holes overflowing with glue and blocking holes, and inconvenient fixing of mobile phone cases, so as to reduce the risk of overflowing glue and hole blocking and meet the needs of use needs, benefits of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

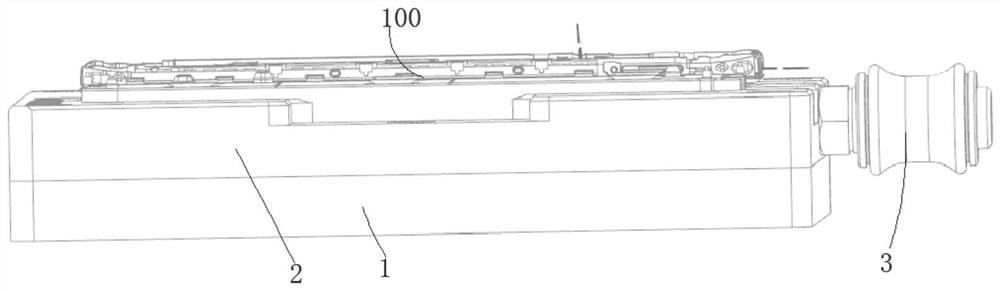

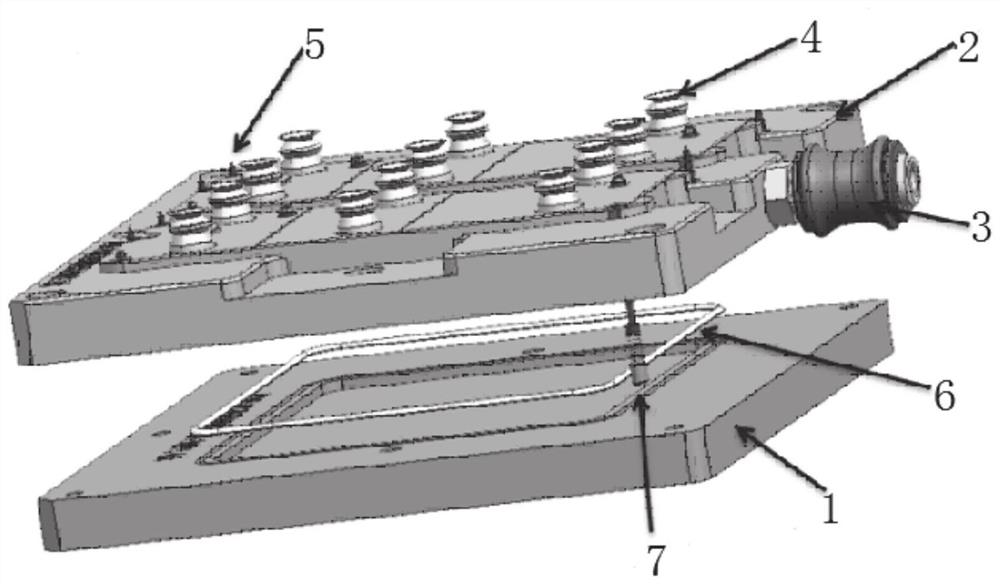

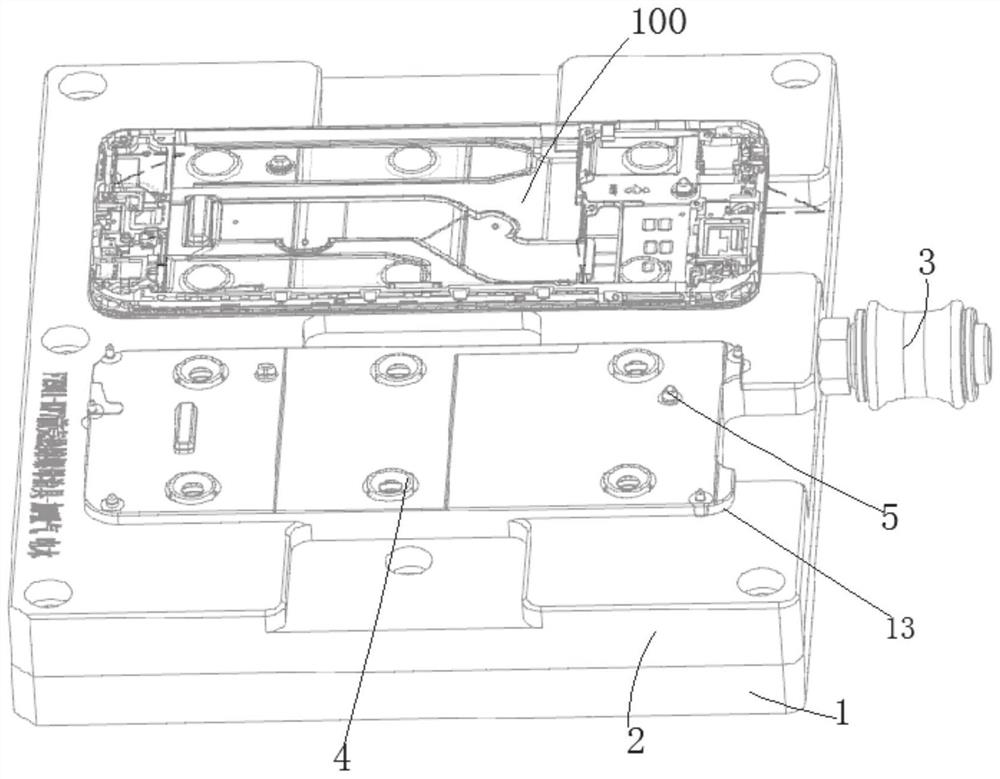

[0023] refer to Figure 1-4 , this embodiment proposes an automatic hot-melt nut jig, including an automatic hot-melt nut jig body, the automatic hot-melt nut jig body includes a bottom plate 1, the top of the bottom plate 1 is screwed with a base 2, and the bottom of the base 2 is provided with Groove 8, the bottom of the base 2 is bonded and fixed with a sealing ring 6 matching the groove 8, the bottom plate 1 is movably sleeved on the sealing ring 6, and the right side of the base 2 is fixedly installed with a hand slide valve 3, the hand slide valve The air inlet end of 3 communicates with the right inner wall of the groove 8, and the groove 8 is provided with a plurality of connecting pipes 9, and the top of the base 2 is provided with two placement grooves 13, and the product 100 is placed in the placement groove 13, and the connection The top of the tube 9 extends into the corresponding placement groove 13 and communicates with and fixes the suction cup 4. The base 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com