Deplating process of cover glass with holes and protective cover glass for large screen

A cover glass and stripping technology, applied in the field of glass processing, can solve the problems of complex processing technology, large amount of raw materials, waste of manpower and material resources, etc., and achieve the effects of process safety, environmental protection, material and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

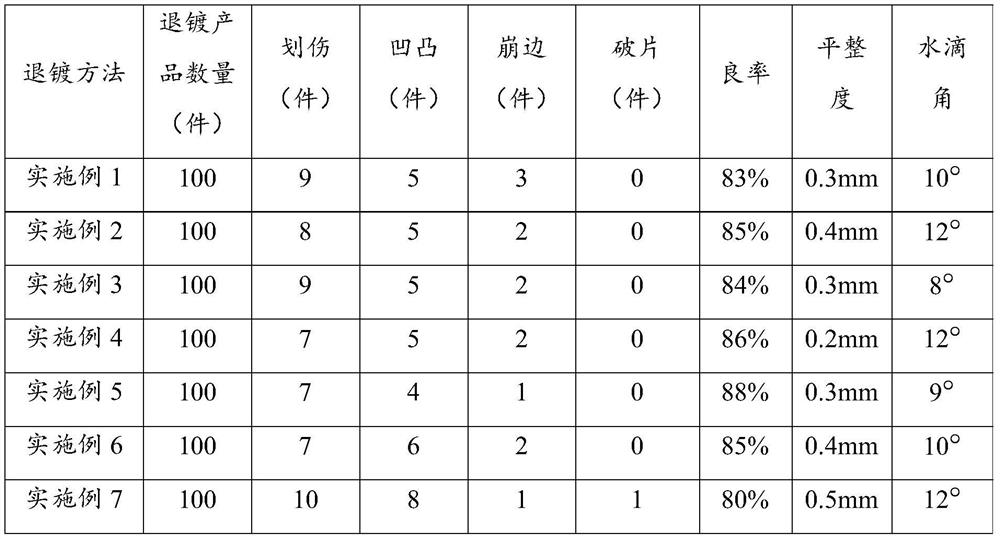

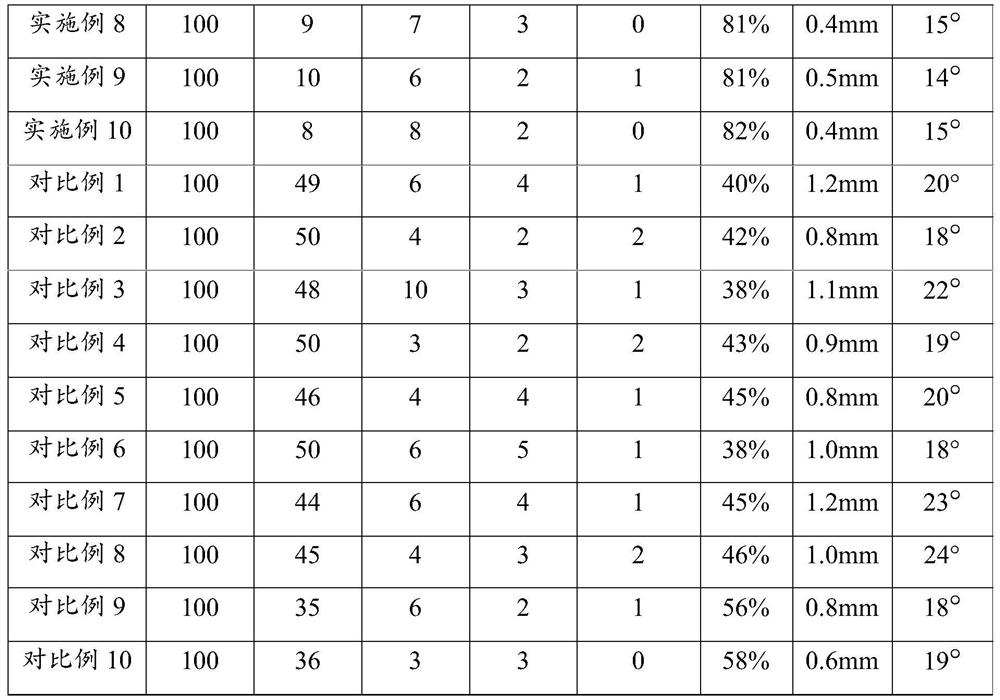

Examples

Embodiment 1

[0111] A kind of deplating process of cover plate glass with holes, comprising the following steps:

[0112] (a) Preparation before stripping:

[0113] Insert the defective glass on the deplating rack in order; use stainless steel needles to carry high-temperature wires through the through holes of the defective glass one by one, and then fix the high-temperature wires horizontally on the deplating rack;

[0114] (b) Acidic deplating: Place the deplating rack with glass in the deplating tank for deplating, turn on the air blowing, the air flow is 1L / min, and add SH-508 from Sihui Company in the deplating tank Paint remover, the deplating temperature is 90°C, the deplating time is 6min, and the bath height is 5cm higher than the glass;

[0115] (c) Cleaning: cut off the high-temperature wire, rinse the glass surface with a high-pressure water gun, and the water outlet pressure of the high-pressure water gun is 100psi;

[0116] (d) Alkaline deplating cleaning: place the deplat...

Embodiment 2

[0121] A kind of deplating process of cover plate glass with holes, comprising the following steps:

[0122] (a) Preparation before stripping:

[0123] Insert the defective glass on the deplating rack in order; use stainless steel needles to carry high-temperature wires through the through holes of the defective glass one by one, and then fix the high-temperature wires horizontally on the deplating rack;

[0124] (b) Acidic deplating: Place the deplating rack with glass in the insert for deplating in the deplating tank, turn on the air blowing, the air flow rate is 1.5L / min, and add the SH- 508 paint remover, the deplating temperature is 85°C, the deplating time is 8min, and the bath height is 5cm higher than the glass;

[0125] (c) Cleaning: Cut off the high-temperature wire, rinse the glass surface with a high-pressure water gun, and the water outlet pressure of the high-pressure water gun is 80psi;

[0126] (d) Alkaline deplating cleaning: place the deplating rack with gl...

Embodiment 3

[0131] A kind of deplating process of cover plate glass with holes, comprising the following steps:

[0132] (a) Preparation before stripping:

[0133] Insert the defective glass on the deplating rack in order; use stainless steel needles to carry high-temperature wires through the through holes of the defective glass one by one, and then fix the high-temperature wires horizontally on the deplating rack;

[0134] (b) Acidic deplating: place the deplating rack with glass in the insert for deplating in the deplating tank, turn on the air blowing, the air flow rate is 1.2L / min, and add the SH- 508 paint remover, the deplating temperature is 95°C, the deplating time is 4min, and the bath height is 5cm higher than the glass;

[0135] (c) Cleaning: Cut off the high-temperature wire, rinse the glass surface with a high-pressure water gun, and the water outlet pressure of the high-pressure water gun is 120psi;

[0136] (d) Alkaline deplating cleaning: place the deplating rack with gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com