Round tower-shaped preprocessor

A preprocessor and tower-shaped technology, applied in the direction of solid separation, flotation, etc., can solve the problems of power consumption, flotation cost increase, complex structure, etc., achieve stable operation and solve the effect of uneven dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

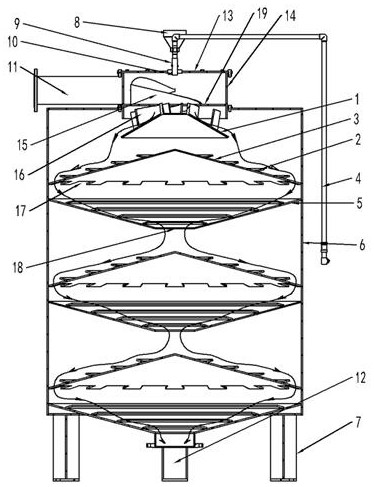

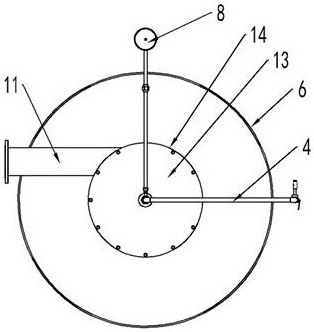

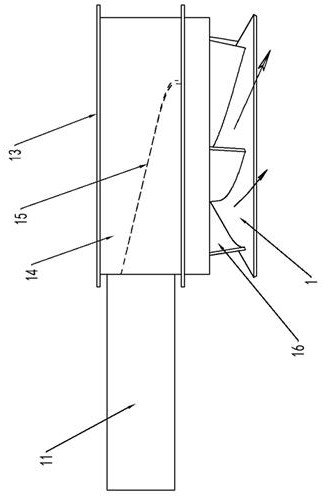

[0024] Example 1, such as Figure 1-5 As shown, a round tower-shaped preprocessor includes a hollow tower body 6, a mixing device is arranged in the tower body flow 6, a liquid distribution device is arranged on the upper end of the tower body 6, and an atomizing device is connected to the liquid distribution device.

[0025] The liquid distribution device includes a cylindrical body 14 with a circular cross section. The cylindrical body 14 is fixedly installed on the upper end of the tower body 6 , and the lower end of the cylindrical body 14 is inserted into the upper end of the tower body 6 for a certain distance.

[0026] The upper end of the cylindrical body 14 is provided with an upper cover 13 , and one side of the cylindrical body 14 is fixedly installed with an untreated pulp delivery pipe 11 , and the unprocessed ore slurry delivery pipe 11 communicates with the cylindrical body 14 .

[0027] The axis of the slurry delivery pipe 11 to be processed is parallel to the ...

Embodiment 2

[0047] Embodiment 2, in above-mentioned embodiment 1, such as Image 6 As shown, each leg 7 is respectively provided with a telescopic rod 20 capable of telescopic expansion, and the leg 7 is provided with a cavity 21 for accommodating the telescopic rod 20, and the lower end of the cavity 21 penetrates to the lower end surface of the leg 7, so that Stretch out at telescoping rod 20.

[0048] A first threaded rod 22 is disposed in the cavity 21 , and the axial direction of the first threaded rod 22 is the same as a certain direction of the telescopic rod 20 .

[0049] The upper end of the first screw rod 22 is fixedly connected to the inner top of the cavity 21 through a bearing seat, and the other end is inserted into the telescopic rod 20 for a certain distance, and the telescopic rod 20 is provided with a screw hole for accommodating the first screw rod 22 .

[0050] The cross section of the telescopic rod 20 is rectangular, which can prevent the telescopic rod 20 from rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com