Three-cylinder bidirectional stepped ball mill

A two-way step and ball mill technology, applied in grain processing and other directions, can solve the problems of uncontrollable movement of spheres, inability of materials to be evenly ground and limited by the direction of rolling, etc., to improve contact area and uniformity, improve accuracy, and improve use. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

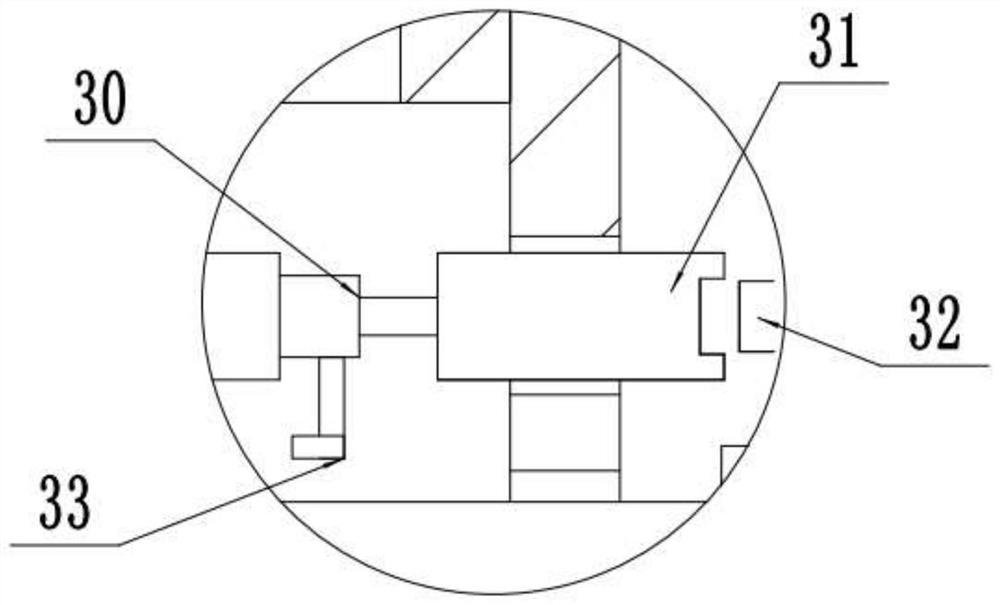

[0016] see Figure 1-2 , a three-cylinder two-way stepped ball mill, including a ball mill mechanism for input grinding of materials to be polished; the ball mill mechanism includes an upper outer cylinder 10, and a set of upper outer cylinder 10 is arranged inside the upper outer cylinder 10 The upper inner cylinder 15 of the coaxial line, the middle part of the left side wall of the upper inner cylinder 15 is rotatably connected with a group of servo motors 14 fixed on the left outer wall of the upper outer cylinder 10 through a coupling. 14 drives the upper inner cylinder 15 to rotate inside the servo motor one 14. One end of the upper inner cylinder 15 is rotatably connected with a group of feed channels 13 in an L-shaped structure placed outside the right side wall of the upper outer cylinder 10, and the materials to be crushed are input into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com