Storage battery pole plate wrapping mechanism and automatic storage battery pole group wrapping production line

A storage battery and production line technology, which is applied in battery assembly machines, secondary battery manufacturing, and final product manufacturing. It can solve the problems of manual coordination of stacked pole groups, affecting work efficiency, and easy scattering of positive and negative plates. Achieve the effect of saving labor, saving power and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

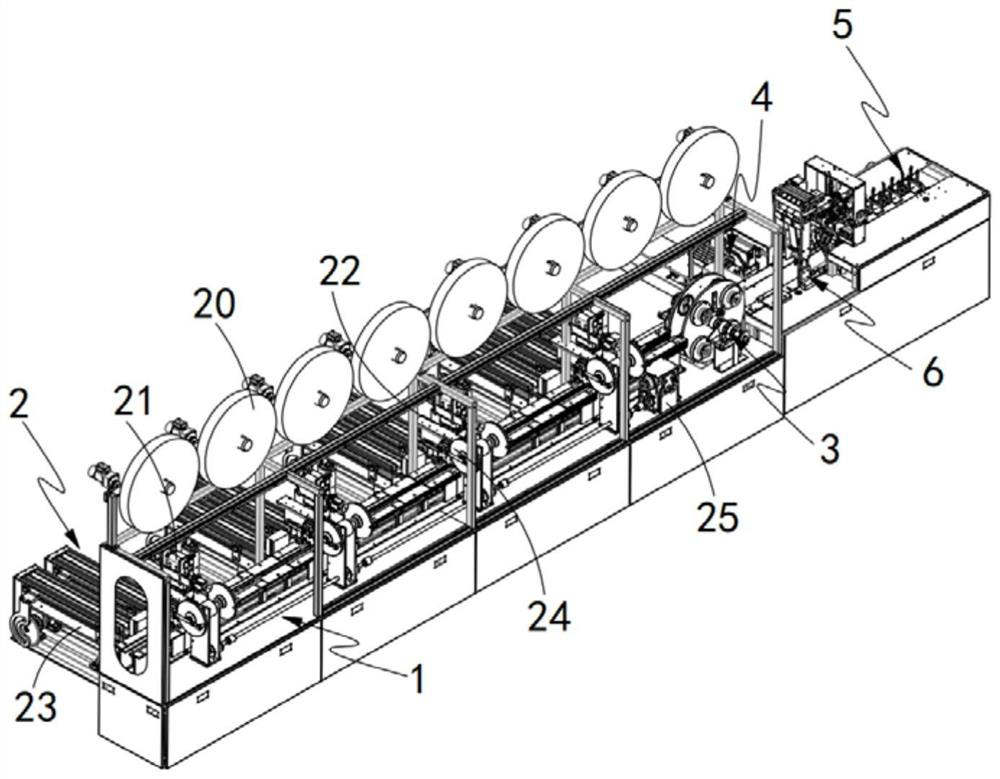

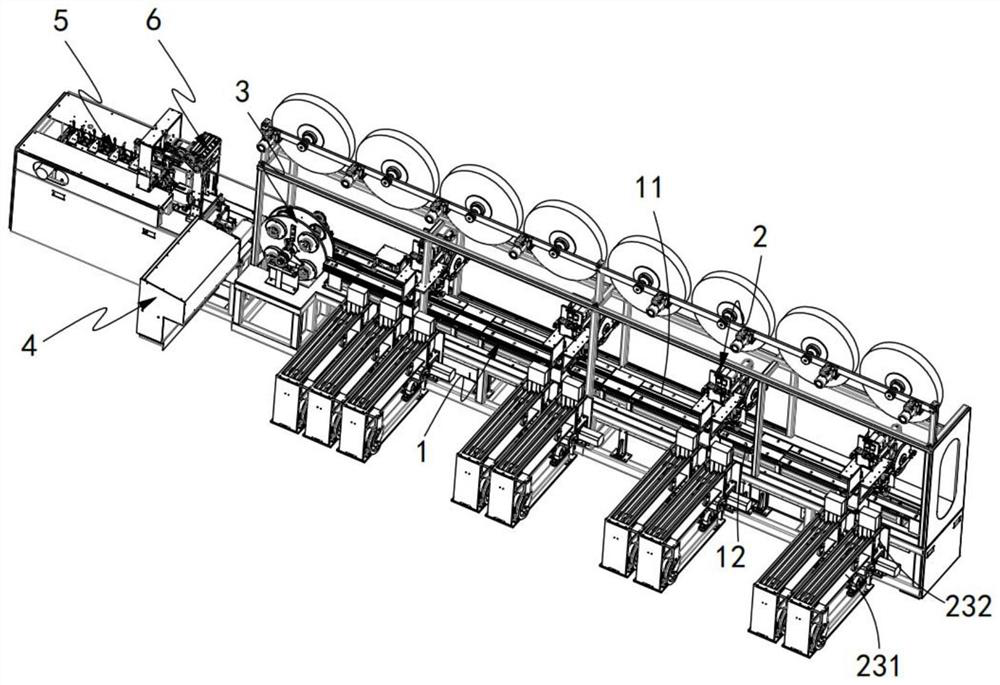

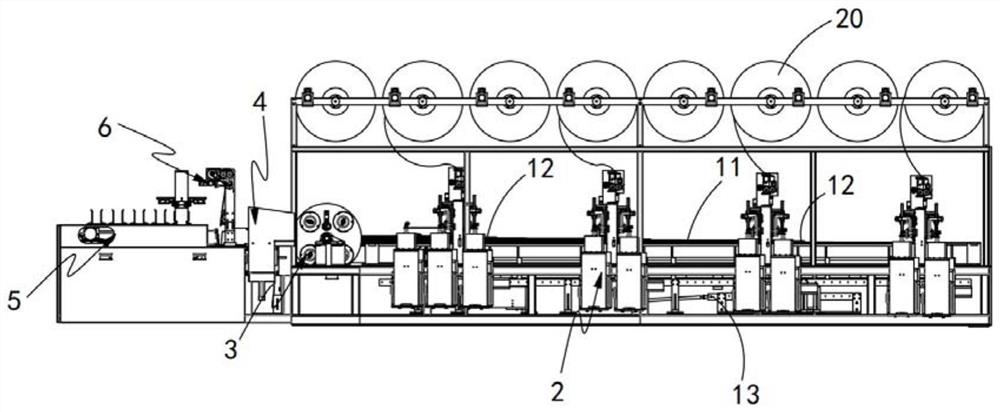

[0045] Such as figure 1 , 4 Shown in and 7, a battery pole plate wrapping mechanism, comprises the separator paper 20 of continuous supply, is characterized in that, also comprises:

[0046] The stacking assembly 12, the stacking assembly 12 respectively carries the positive and negative plates on both sides of the vertically transported separator paper 20, and a height difference is formed between the positive plate and the negative plate carried by the stacking assembly 12 In the process of the positive / negative plate being pushed towards the negative / positive plate for plugging to form a wrapping unit, the separator paper 20 is wrapped on the outside of the pushed positive / negative plate so that the positive / negative plate is connected to the other A negative / positive plate is separated.

[0047] The battery plate wrapping mechanism according to claim 1, wherein the stacking assembly 12 includes a plate receiving piece A121 and a plate receiving piece B122, and the plate ...

Embodiment 2

[0049] Such as Figures 1 to 3 , 6 and 7, wherein the parts identical or corresponding to Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 are described below: Embodiment 2 and Embodiment 1 One difference is:

[0050] An automatic sheet wrapping production line for battery pole groups, characterized in that it includes a sheet conveying mechanism 1, a number of sheet wrapping mechanisms 2 arranged on the conveying channel of the sheet conveying mechanism 1, and a transfer mechanism arranged at the tail end of the sheet conveying mechanism 1. Mechanism 3, a patching mechanism 4 and an erecting mechanism 5 arranged at the output end of the transfer mechanism 3, the lamination conveying mechanism 1 includes a linear passage 11 and a push assembly 13, each of the stacking assemblies 12 is placed in the linear passage 11 An equidistant height difference is set, and the pushing component 13 p...

Embodiment 3

[0057] Such as Figure 4 , 5 , 9, where the same or corresponding components as in Embodiment 1 are designated with reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below: the differences between Embodiment 3 and Embodiment 1 The difference is:

[0058] In this embodiment, the wrapping mechanism 2 further includes a paper feeding assembly 21, a cutting assembly 22, a board feeding assembly 23, a suction board assembly 24, and a driving assembly 25, and the paper feeding assembly 21 conveys the compartments from top to bottom. The board paper 20, the cutting assembly 22 is arranged on the conveying path of the separator paper 20, the cutting assembly 22 cuts the separator paper, and the board feeding assembly 23 is arranged on the stack conveying mechanism 1 for continuous supply of positive and negative plates, the suction plate assembly 24 is arranged at the end of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com