Gasification/combustion performance testing device for solid fuel under pressurized oxygen-water vapor condition and use method of gasification/combustion performance testing device

A technology of solid fuel and combustion performance, applied in measurement devices, fuel oil testing, analysis materials, etc., can solve problems such as shortages, and achieve the effects of improving combustion efficiency, enriching CO2, and reducing flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

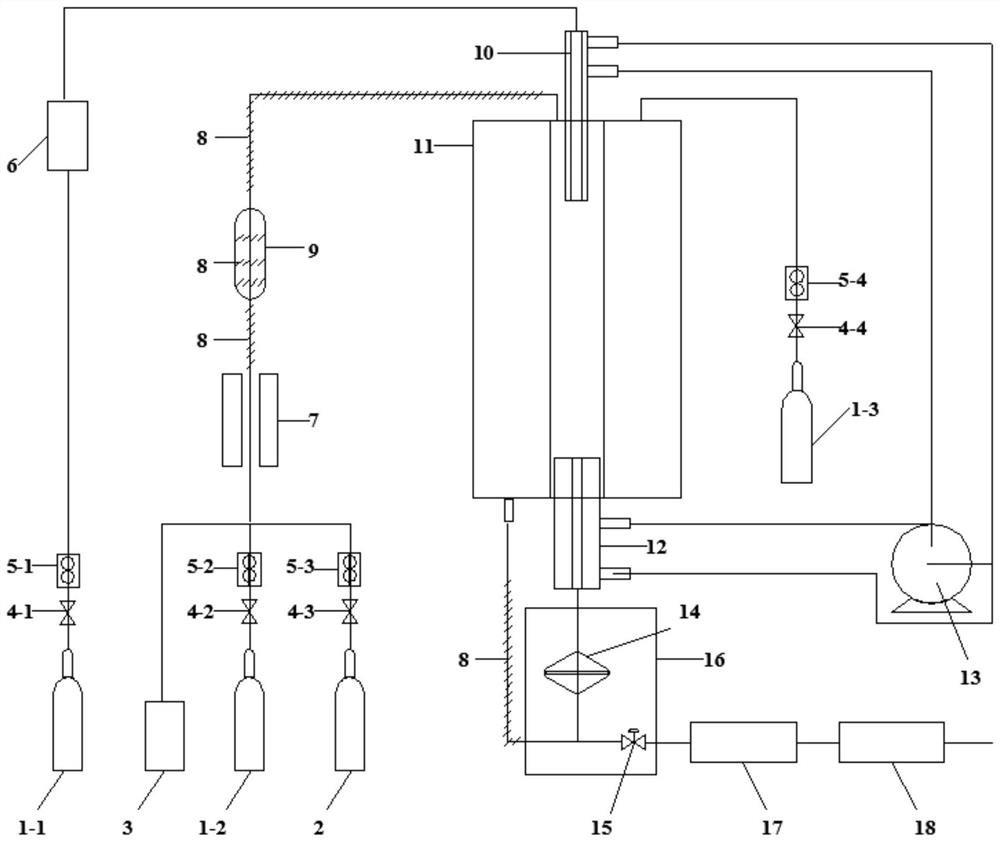

[0032] Specific implementation mode one: combine figure 1 Describe this embodiment in detail. This embodiment is a gasification / combustion performance testing device for solid fuel under pressurized oxygen-steam conditions, which includes a first inert gas tank 1-1, a second inert gas tank 1-2, The third inert gas tank 1-3, oxygen tank 2, high pressure constant flow water injection pump 3, pressurized powder feeder 6, preheating furnace 7, heating belt 8, premix tank 9, oil circulation sampling gun 10, one-dimensional Furnace 11, oil circulation sampling gun 12, gas-solid separator 14, high temperature resistant back pressure valve 15, constant temperature box 16, water vapor separator 17 and flue gas analyzer 18;

[0033] The first inert gas tank 1-1 communicates with the pressurized powder feeder 6, and the pressurized powder feeder 6 communicates with the inlet of the oil circulation sampling gun 10; the high-pressure constant flow water injection pump 3, the second inert g...

specific Embodiment approach 2

[0062] Embodiment 2: This embodiment differs from Embodiment 1 in that: the circulating oil circulation sampling gun 10 and the oil circulation sampling gun 12 are provided with a high-temperature-resistant and heat-conducting oil layer. Others are the same as in the first embodiment.

[0063] In this specific embodiment, the oil circulation sampling gun 10 and the oil circulation sampling gun 12 have oil inlet and outlet ports on the outside and cavities inside.

specific Embodiment approach 3

[0064] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: use the oil circulation temperature controller 13 to circulate and control the oil layer and the oil layer temperature set outside the oil circulation sampling gun 10 and oil circulation sampling gun 12 . Others are the same as in the first or second embodiment.

[0065] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT The oil circulation temperature controller 13 can be heated to not lower than 230°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com