Method for detecting iron ions in hydrolysate prepared from buffalo horn powder and application of method in Qingkailing hydrolysate

A technology of hydrolyzate and iron ions, which is applied in the field of iron ion detection, can solve problems such as inapplicability of detection methods, achieve the effects of avoiding waste of production resources, improving scientific and accurate route design, and improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 Stability and Verification of Accuracy

[0065] Taking the iron ion determination of Qingkailing hydrolyzate as an example, the following method is used to detect the iron ion content in the hydrolyzate.

[0066] Configuration of starch indicator solution: Weigh 0.5g of soluble starch, add 5mL of water, stir evenly, slowly add 100mL of boiling water, and stir, continue to boil for 2min after adding, cool to room temperature, take the supernatant, and get ready.

[0067] method 1:

[0068] Indirect iodometric method: Take 10mL of brown-red hydrolyzate at 50±5℃ in a transparent tube, add 1mL of 6mol / L hydrochloric acid, shake and shake well, add 2g of potassium iodide powder, shake and shake well, then add the prepared starch indicator solution 2mL, the hydrolyzed solution shows blue color, add 0.001mol / L sodium thiosulfate standard solution and titrate until the blue color disappears as the end point.

[0069] Method 2:

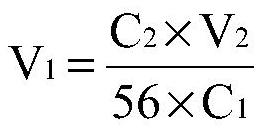

[0070] Pretreatment: Take 10mL of th...

Embodiment 2

[0077] Embodiment 2 judges whether the iron ion content exceeds the limit in the hydrolyzate

[0078] S1. Pretreatment: Take 10mL of the brown-red hydrolyzate at 50±5°C in a transparent tube, add 10g of iodoacetamide, and shake well to obtain a colorless pretreatment solution. Wherein, the content of amino acid in the hydrolyzate is 0.02g / mL.

[0079] S2. Result determination:

[0080] S2-1. Add 1mL of 6mol / L hydrochloric acid, shake well;

[0081] S2-2. Add 2mL of prepared starch indicator solution, and the hydrolyzed solution turns blue;

[0082] S2-3. Titrate with 0.001mol / L sodium thiosulfate standard solution, shake and shake for 30 seconds;

[0083] S2-4. The blue color faded, and the solution was shaken for 30 seconds, and it was still colorless after standing for 3 to 5 minutes, indicating that the hydrolyzed solution was Fe 2+ and / or Fe 3+ The ion concentration meets the requirements for the preparation of the hydrolyzate.

Embodiment 3

[0084] Embodiment 3 Judging whether the iron ion content exceeds the limit in the hydrolyzate

[0085] S1. Pretreatment: Take 10mL of the brown-red hydrolyzate at 50±5°C in a transparent tube, add 5g of iodoacetamide, and shake well to obtain a colorless pretreatment solution. Wherein, the content of amino acid in the hydrolyzate is 0.01g / mL.

[0086]S2. Result determination:

[0087] S2-1. Add 1mL of 6mol / L hydrochloric acid, shake well;

[0088] S2-2. Add 2mL of prepared starch indicator solution, and the hydrolyzed solution turns blue;

[0089] S2-3. Add 8 mL of 0.001 mol / L sodium thiosulfate standard solution, shake well for 30 seconds;

[0090] S2-4. The blue color faded, and the solution was shaken for 30 seconds, and it was still colorless after standing for 3 to 5 minutes, indicating that the hydrolyzed solution was Fe 2+ and / or Fe 3+ The ion concentration meets the requirements for the preparation of the hydrolyzate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com