Automatic fluorescence detection equipment

A detection device and automatic fluorescence technology, applied in the field of fluorescence detection, can solve problems such as low work efficiency, cumbersome work procedures, errors, etc., and achieve the effects of flexible use, simple placement of slides, and high movement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

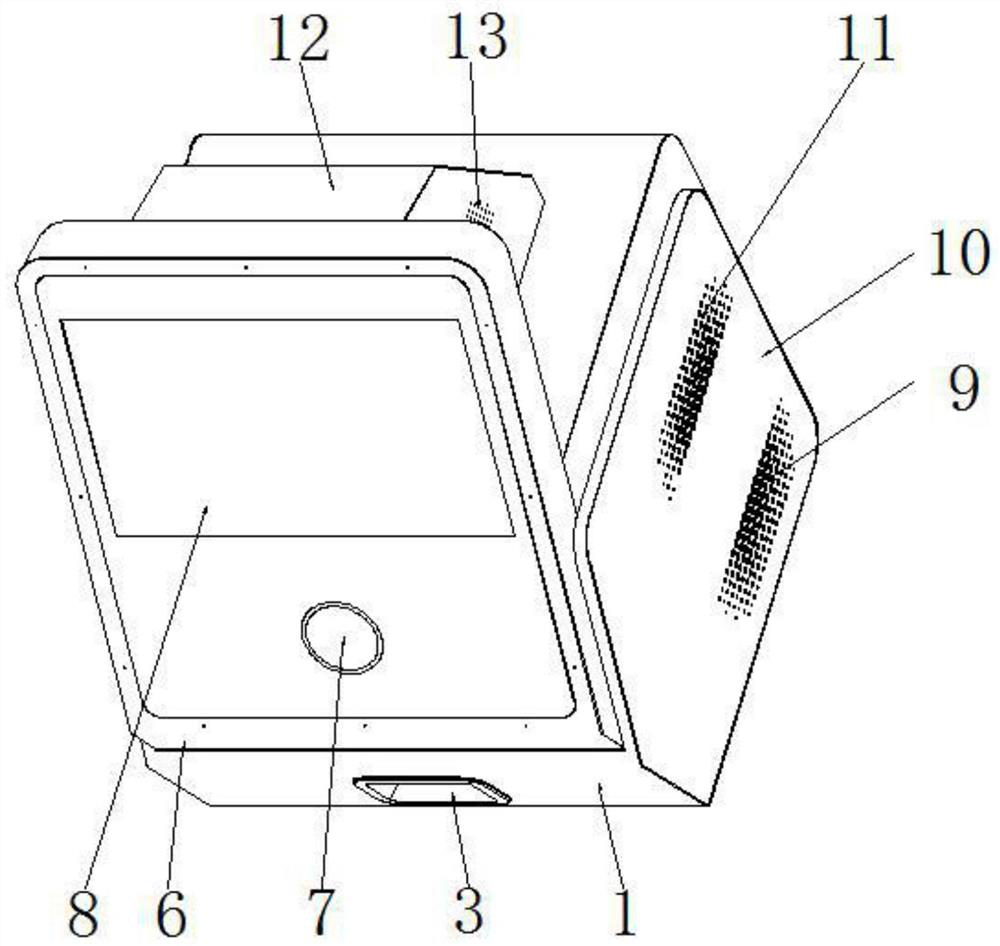

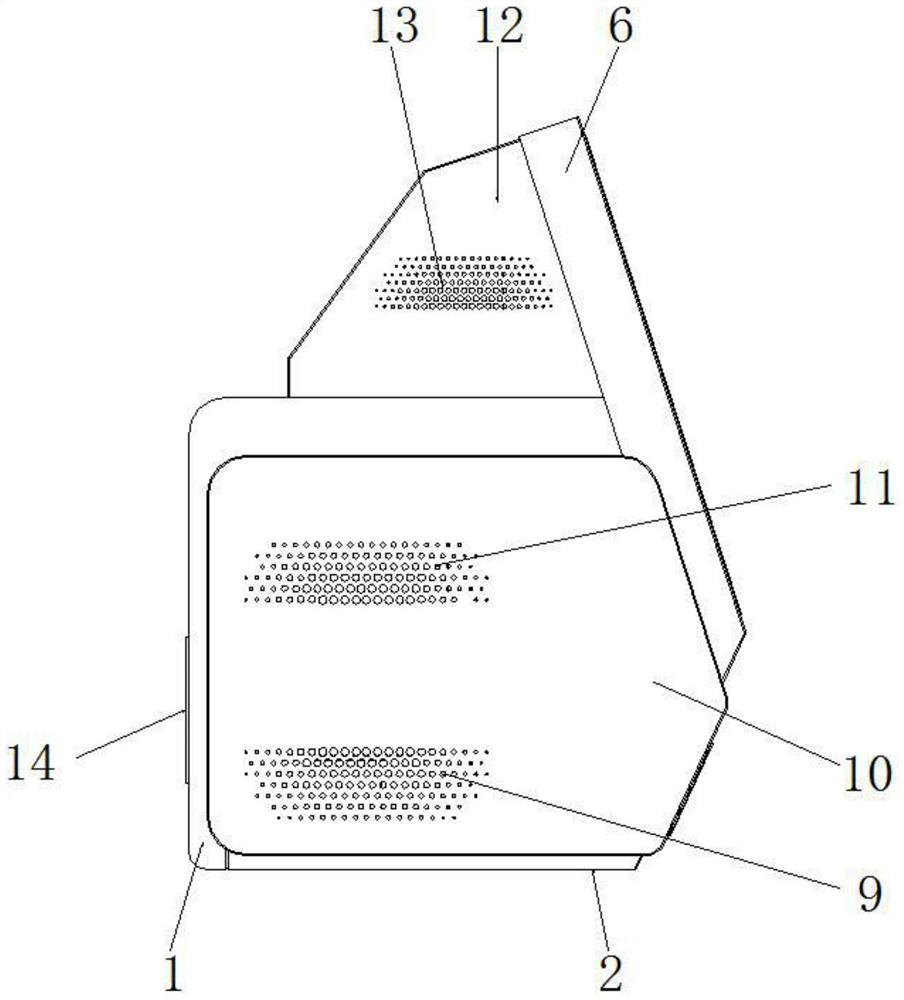

[0038] Specific implementation mode one, refer to Figure 1-13 , the present invention provides a technical solution: an automatic fluorescence detection device, comprising a lower body 1, an upper body 5 and a PC 6, the bottom of the lower body 1 is provided with a base 2, and the upper end of the lower body 1 is equipped with an upper body 5 , the upper body 5 is equipped with a PC 6, and the rear of the PC 6 is provided with a rear cover 12, the left end of the upper surface of the base 2 is vertically fixed with a left fixing plate 15, and the right end of the upper surface of the base 2 is vertically fixed with a right Fixed plate 25, the middle part of left fixed plate 15 and right fixed plate 25 is connected with horizontal frame plate 17, and the upper end of left fixed plate 15 and right fixed plate 25 is all supported on the bottom surface of top plate 28, and the middle part of top plate 28 is equipped with microscope 21, and the lower front end of the microscope 21...

specific Embodiment approach 2

[0040] Specific embodiment two, this embodiment is a further limitation to specific embodiment one, on the mobile platform 27 in the present invention, there are two motion directions of X and Y axes, and each motion direction is controlled by a high-precision stepping motor and a high-precision motor. Driven by the screw rod, it is convenient to move the installation groove 31 on the mobile platform 27 in the left and right or front and rear directions. And it is more flexible to use.

specific Embodiment approach 3

[0041] Embodiment 3. This embodiment is a further limitation of Embodiment 1. In the present invention, the opening groove 3 provided on the front side of the lower body 1 is provided with a scanning port 4, and the front end of the installation groove 31 on the mobile platform 27 It is convenient to protrude a part out of the scanning port 4 when moving forward, so that the inspection staff can place the slide glass on the installation groove 31, and the insertion and extension are fast, the slide glass is easy to place, and the use is more intelligent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com