A kind of electrocatalytic material and its preparation method and application

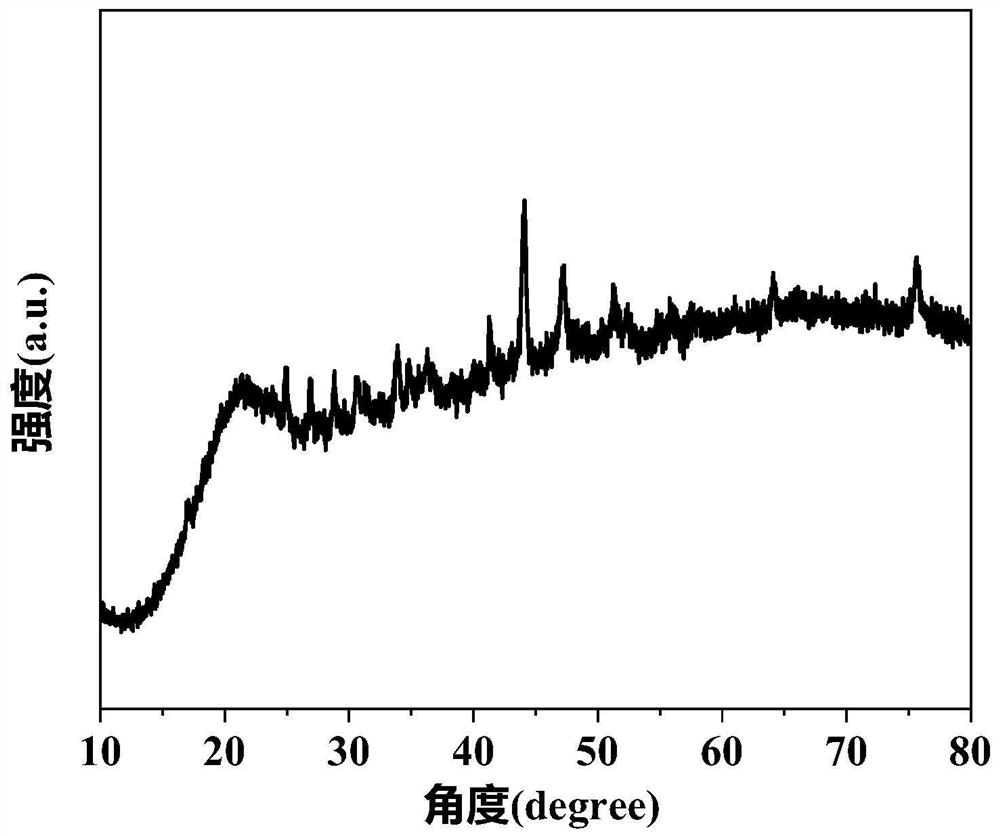

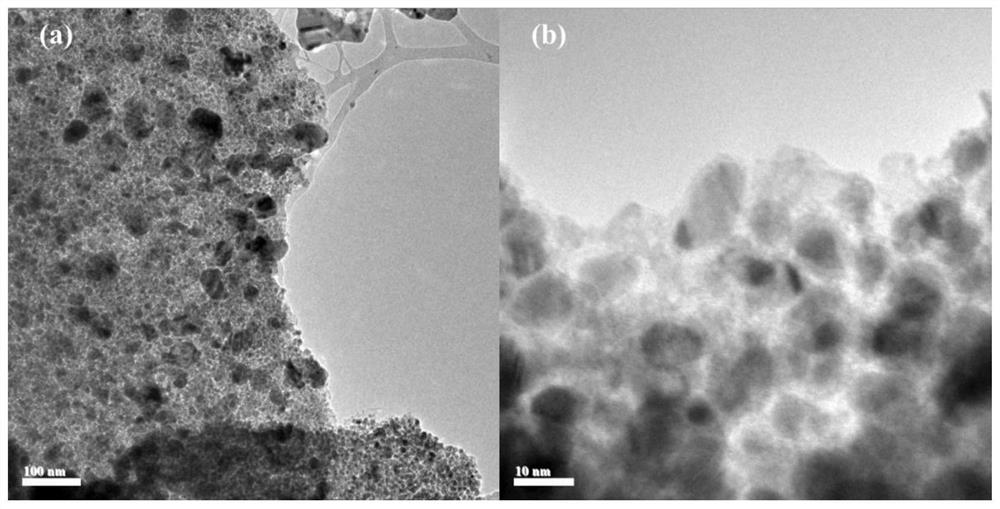

An electrocatalytic material and conductive substrate technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of small specific surface area, poor conductivity of cobalt molybdenum oxide, low charge transfer efficiency, etc., achieve high catalytic activity, good catalytic performance, and improve catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

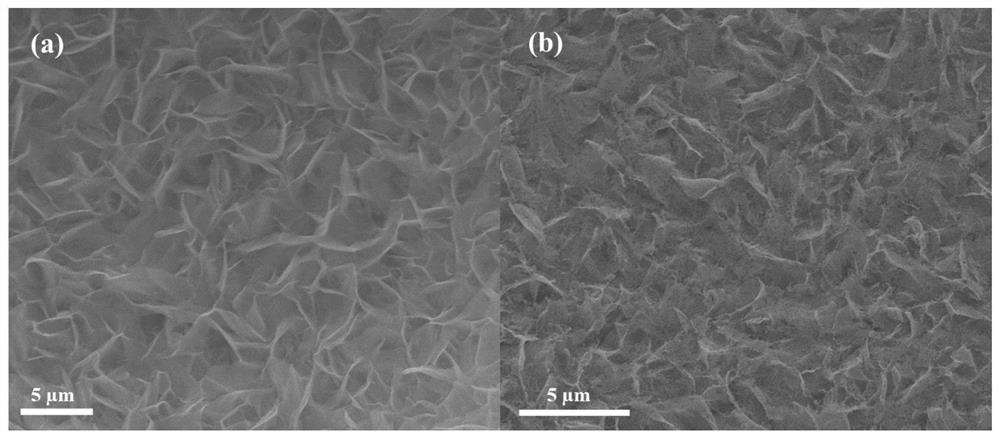

[0053] In this embodiment, an electrocatalytic material is prepared, and the specific process is as follows:

[0054] S1: A piece of NF (2.4cm*3cm) was ultrasonically cleaned with ethanol, acetone and 3mol / L hydrochloric acid aqueous solution for 30 minutes to remove oil and nickel oxide on the surface, and then washed with deionized water for 10 minutes, repeated 3 times. Then 146mg of Co(NO 3 ) 2 ·6H 2 O, 210mg of C 6 h 12 N 4 And the PVP of 255mg is dissolved in the mixed solution of 40mL deionized water and ethanol (H 2 O:ethanol=3:1, v / v). Transfer the mixed solution to a stainless steel autoclave lined with 50mL Teflon, immerse a piece of cleaned NF in the mixed solution and raise the temperature from room temperature to 120°C at a heating rate of 5°C / min, maintaining 120 ℃ for 12 hours, cooled to room temperature naturally, washed with deionized water and dried in an oven at 70 ℃;

[0055] S2: 582.1mg of Co(NO 3 ) 2 ·6H 2 O was dissolved in 120 mL of deionize...

Embodiment 2

[0058] In this embodiment, an electrocatalytic material is prepared, and the specific process is as follows:

[0059] S1: A piece of NF (2.4cm*3cm) was ultrasonically cleaned with ethanol, acetone and 3mol / L hydrochloric acid aqueous solution for 30 minutes to remove oil and nickel oxide on the surface, and then washed with deionized water for 10 minutes, repeated 3 times. Then 146mg of Co(NO 3 ) 2 ·6H 2 O, 210mg of C 6 h 12 N 4 and 255 mg of PVP were dissolved in 40 mL of deionized water. Transfer the mixed solution to a stainless steel autoclave lined with 50mL Teflon, immerse a piece of cleaned NF in the mixed solution and raise the temperature from room temperature to 120°C at a heating rate of 5°C / min, maintaining 120 ℃ for 12 hours, cooled to room temperature naturally, washed with deionized water and dried in an oven at 70 ℃;

[0060] S2: 582.1mg of Co(NO 3 ) 2 ·6H 2 O was dissolved in 120 mL of deionized water, heated to 80 °C, and then the nanosheet array pr...

Embodiment 3

[0063] In this embodiment, an electrocatalytic material is prepared, and the specific process is as follows:

[0064] S1: A piece of NF (2.4cm*3cm) was ultrasonically cleaned with ethanol, acetone and 3mol / L hydrochloric acid aqueous solution for 30 minutes to remove oil and nickel oxide on the surface, and then washed with deionized water for 10 minutes, repeated 3 times. Then 146mg of Co(NO 3 ) 2 ·6H 2 O, 210mg of C 6 h 12 N 4 and 255 mg of SDS were dissolved in a mixed solution of 40 mL of deionized water and ethanol (H 2 O:ethanol=5:1, v / v). Transfer the mixed solution to a stainless steel autoclave lined with 50mL Teflon, immerse a piece of cleaned NF in the mixed solution and raise the temperature from room temperature to 140°C at a heating rate of 5°C / min, maintaining 120 ℃ for 12 hours, cooled to room temperature naturally, washed with deionized water and dried in an oven at 70 ℃;

[0065] S2: 1.1642g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 120 mL of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com