A kind of preparation method of vitamin K2

A vitamin and acetone technology, applied in the field of vitamin K2 preparation, can solve the problems of high cost, low extraction rate, low production efficiency, etc., and achieve the effect of avoiding waste and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

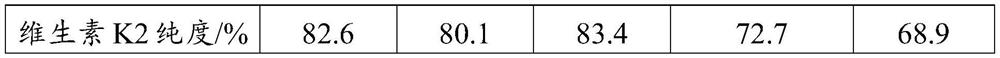

Examples

Embodiment 1

[0027] A preparation method of vitamin K2, comprising the steps of:

[0028] (1) Insert the culture medium of Bacillus natto as follows in the fermenter: glucose 2g / L, peptone 20g / L, ammonium sulfate 0.5%, K 2 HPO 4 2g / L, KH 2 PO 4 1g / , CaCl 2 0.1g / L, MgSO 4 1g / L. Then, the Bacillus natto was inserted into the culture medium, and the fermentation conditions were as follows: the fermentation temperature was 37° C., the initial pH value was 8.0, the inoculum size was 6%, and the fermentation time was five days.

[0029] (2) According to the ratio that the concentration of the composite flocculant in the fermentation broth is 50mg / L, add the composite flocculant (by polyaluminum chloride and 2Na 2 CO 3 ·3H 2 o 2 Mix according to the ratio of mass ratio of 5:1), stir and let it stand, after the Bacillus natto cells settle, use a tube with filtering function to extract the supernatant liquid from the upper layer, which is the liquid to be extracted, and set aside.

[...

Embodiment 2

[0034] A preparation method of vitamin K2, comprising the steps of:

[0035] (1) Insert the culture medium of Bacillus natto as follows in the fermenter: glucose 2g / L, peptone 20g / L, ammonium sulfate 0.5%, K 2 HPO 4 2g / L, KH 2 PO 4 1g / , CaCl 2 0.1g / L, MgSO 41g / L. Then, the Bacillus natto was inserted into the culture medium, and the fermentation conditions were as follows: the fermentation temperature was 37° C., the initial pH value was 7.5, the inoculum size was 7.5%, and the fermentation time was five days.

[0036] (2) According to the concentration of the composite flocculant in the fermented liquid is the ratio of 45mg / L, add the composite flocculant (by polyaluminum chloride and 2Na 2 CO 3 ·3H 2 o 2 Mix according to the ratio of mass ratio of 8:1), stir and let it stand, after the Bacillus natto cells settle, use a tube with filtering function to extract the supernatant liquid from the upper layer, which is the liquid to be extracted, and set aside.

[0037...

Embodiment 3

[0041] A preparation method of vitamin K2, comprising the steps of:

[0042] (1) Insert the culture medium of Bacillus natto as follows in the fermenter: glucose 2g / L, peptone 20g / L, ammonium sulfate 0.5%, K 2 HPO 4 2g / L, KH 2 PO 4 1g / , CaCl 2 0.1g / L, MgSO 4 1g / L. Then, the Bacillus natto was inserted into the culture medium, and the fermentation conditions were as follows: the fermentation temperature was 37° C., the initial pH value was 7.5, the inoculum size was 5%, and the fermentation time was five days.

[0043] (2) According to the ratio that the concentration of the composite flocculant in the fermentation broth is 60mg / L, add the composite flocculant (by polyaluminum chloride and 2Na 2 CO 3 ·3H 2 o 2 Mix according to the ratio of 2.5:1 in mass ratio), stir and let it stand, after the Bacillus natto cells settle, use a tube with filtering function to extract the upper clear liquid, which is the liquid to be extracted, and set aside.

[0044] (3) Concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com