Subnanometer wire adhesive and its preparation method and use

A sub-nanometer, adhesive technology, applied in the direction of adhesives, inorganic adhesives, film/flake adhesives, etc. The effect of long sexual action time, high bond strength and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

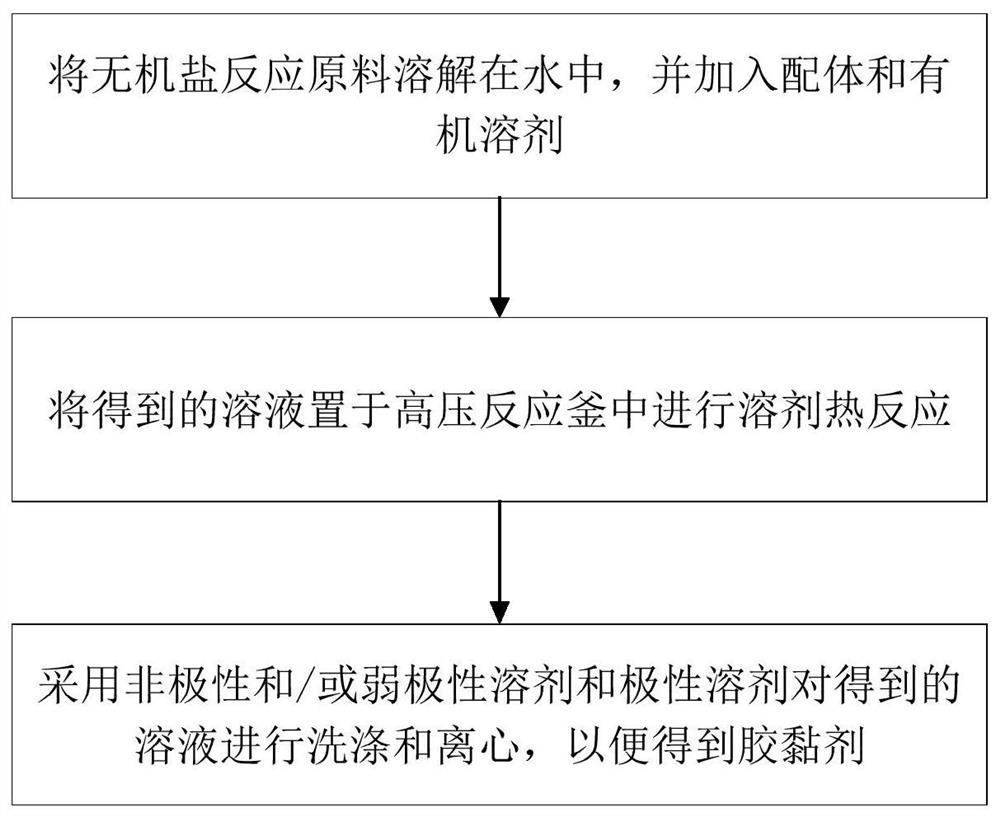

Method used

Image

Examples

Embodiment 1

[0052] 1) Synthesis of bismuth phosphomolybdate subnanowires and obtaining adhesive

[0053] Weigh 0.8g of phosphomolybdic acid and 0.2g of bismuth nitrate into a 40mL reactor, add 16mL of deionized water, and stir for 10 minutes; then add 10mL of octadecene and 6mL of oleylamine, and stir for 10 minutes. Subsequently, the reaction vessel was sealed and placed in an oven at 180° C. for 8 hours and then naturally cooled to room temperature. Pour the product in the reaction kettle into a centrifuge tube, add n-octane and ethanol and centrifuge and wash three times to obtain bismuth phosphomolybdate sub-nanowires. The product obtained by centrifugation contains a small amount of n-octane and ethanol and is in a semi-solid state , which is bismuth phosphomolybdate subnanowire adhesive.

Embodiment 2

[0055] 1) Synthesis of calcium tungstate subnanowires and obtaining adhesives

[0056] Weigh 1g of phosphotungstic acid and 0.123g of calcium nitrate, add to a 40mL reaction kettle, add 16mL of deionized water, stir for 10 minutes; then add 6mL of oleylamine, and stir for 6 hours. Pour the product in the reaction kettle into a centrifuge tube, add n-octane and ethanol and centrifuge and wash it three times to obtain calcium tungstate sub-nanometer wires. The product obtained by centrifugation contains a small amount of n-octane and ethanol, and is in a semi-solid state, which is the calcium tungstate subnanowire adhesive.

Embodiment 3

[0058] 1) Synthesis of strontium tungstate sub-nanowires and obtaining adhesive

[0059] Weigh 1g of phosphotungstic acid and 0.14g of strontium nitrate, add them into a 40mL reaction kettle, add 16mL of deionized water, and stir for 10 minutes; then add 6mL of oleylamine, and stir for 6 hours. Pour the product in the reaction kettle into a centrifuge tube, add n-octane and ethanol and centrifuge and wash it three times to obtain strontium tungstate sub-nanowires. The product obtained by centrifugation contains a small amount of n-octane and ethanol, and is in a semi-solid state, which is the strontium tungstate sub-nanowire adhesive.

[0060] Evaluation of the performance of the subnanowire adhesive prepared in Examples 2 and 3:

[0061] General method: prepare substrates such as steel sheets, glass sheets or polyvinyl chloride sheets, apply the obtained adhesive evenly to stainless steel sheets, glass sheets or polyvinyl chloride sheets and other substrates with a small spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com