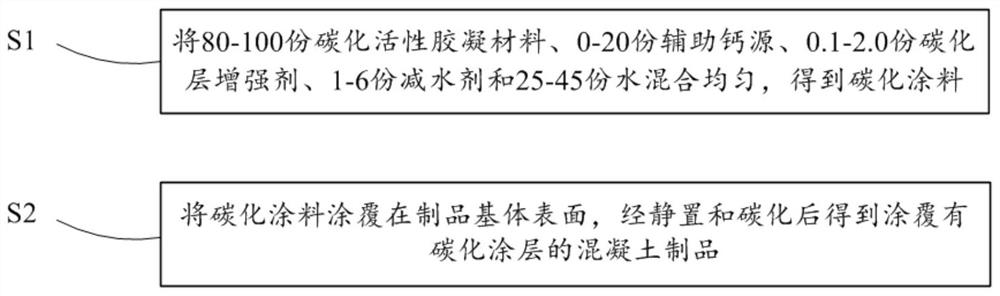

Method for improving durability of concrete product by using carbonized coating

A concrete product and durability technology, applied in the field of building materials, can solve the problems of low efficiency and low utilization rate of maintenance devices, and achieve significant environmental benefits, shorten carbonization time, and improve utilization and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 90 parts of converter steel slag powder, 10 parts of calcium hydroxide, 0.1 part of polyvinyl alcohol (PVA), 0.2 part of sodium carboxymethyl cellulose (CMC), 4 parts of water reducing agent and 34 parts of tap water and mix Evenly, the carbonized coating is obtained; wherein, the calcium hydroxide is chemically pure calcium hydroxide, the water reducing agent is a polycarboxylate superplasticizer with a solid content of 40%, and the water content in the water reducing agent is not included in the weight of water in the number of copies;

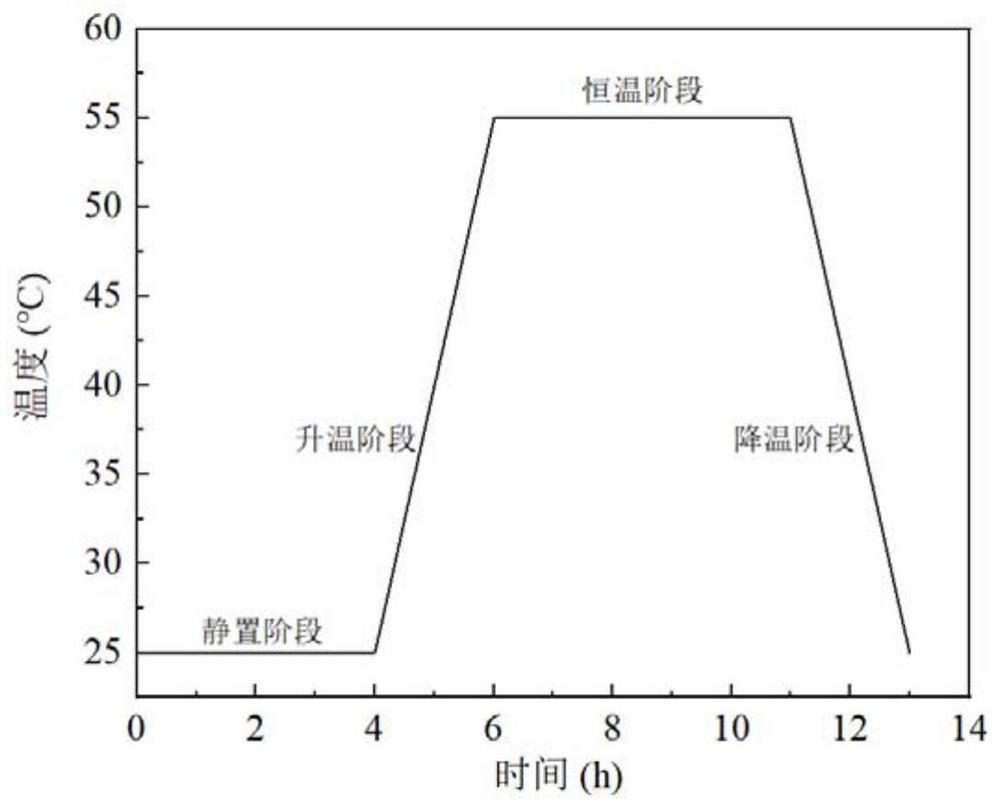

[0035] (2) Spray the above-mentioned carbonized paint on the concrete test block evenly by a spray gun, and the spray thickness is controlled at 0.8-1.2mm, and then the sprayed test block is at a temperature of 20±0.5°C and a relative humidity of 45±0.5% Let stand for 30 minutes in the environment of carbonization, and then put the test block in a carbonization bucket for carbonization to obtain a concrete test block coated wi...

Embodiment 2

[0037] (1) 100 parts of converter steel slag powder, 0.1 part of polyvinyl alcohol (PVA), 0.2 part of sodium carboxymethyl cellulose (CMC), 6 parts of water reducing agent and 28 parts of tap water are mixed and evenly mixed to obtain a carbonized coating; Wherein, the calcium hydroxide is chemically pure grade calcium hydroxide, the water reducing agent is a polycarboxylate superplasticizer with a solid content of 40%, and the water content in the water reducing agent is not counted in the parts by weight of water;

[0038](2) Scratch the above-mentioned carbonized coating on the concrete test block, the thickness of the scraping coating is controlled at 0.8-1.2mm, and then the scrape-coated test block is placed in an environment with a temperature of 20±0.5°C and a relative humidity of 45±0.5% Let stand for 30 minutes, and then place the test block in a carbonization bucket for carbonization to obtain a concrete test block coated with a carbonized coating. Among them, the am...

Embodiment 3

[0040] (1) 80 parts of converter steel slag powder, 20 parts of calcium hydroxide, 0.7 parts of polyvinyl alcohol (PVA), 1.3 parts of sodium carboxymethyl cellulose (CMC), 1 part of water reducing agent, and 45 parts of tap water are mixed and mixed well , to obtain a carbonized coating; wherein, the calcium hydroxide is chemically pure grade calcium hydroxide, the water reducing agent is a polycarboxylate superplasticizer with a solid content of 40%, and the water content in the water reducing agent is not included in the weight of water among the numbers

[0041] (2) Brush the above-mentioned carbonized paint on the concrete test block, the thickness of the brush coating is controlled at 0.8-1.2mm, and then the brushed test block is at a temperature of 20±0.5°C and a relative humidity of 45±0.5% under the environment After standing for 120 minutes, the test block was placed in a carbonization bucket for carbonization to obtain a concrete test block coated with a carbonized c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com