Efficient steel pipe rust removal device based on building construction

A construction and high-efficiency technology, used in grinding drive devices, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low rust removal efficiency, poor working environment, and large volume, and achieve high-efficiency steel pipe grinding and rust removal, reducing The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

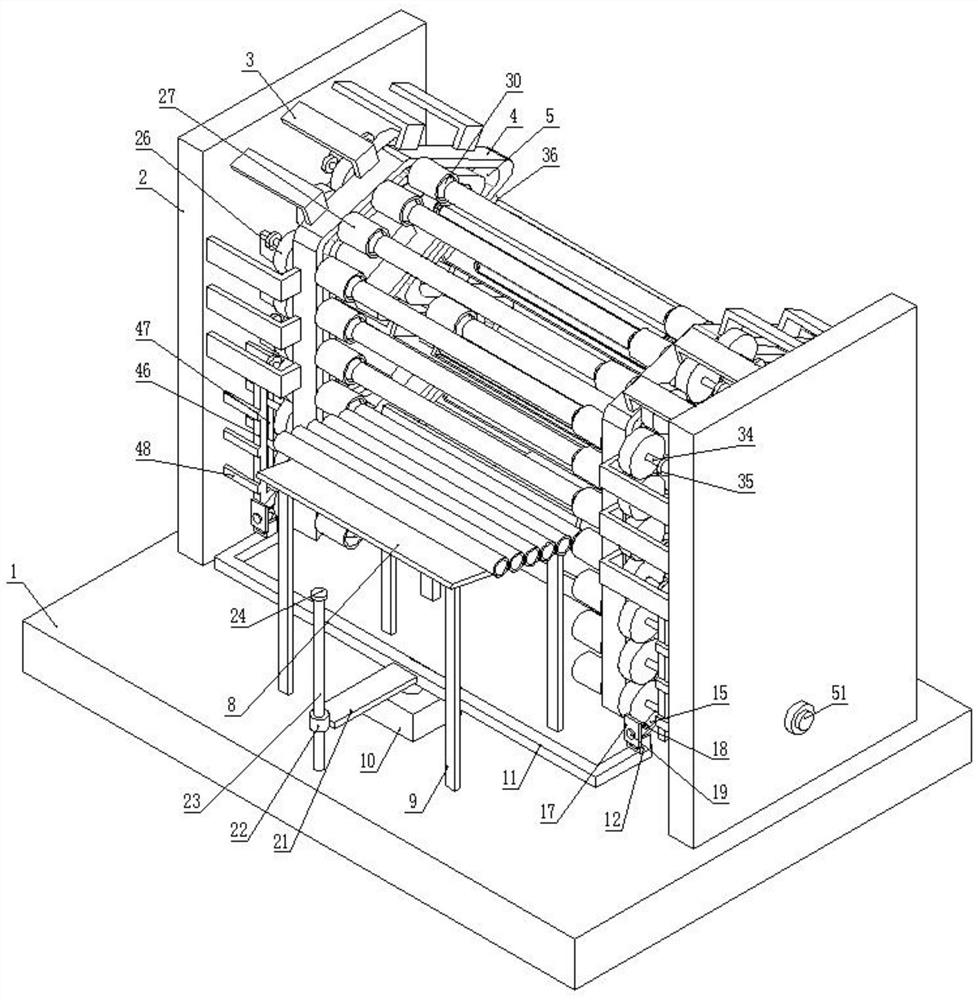

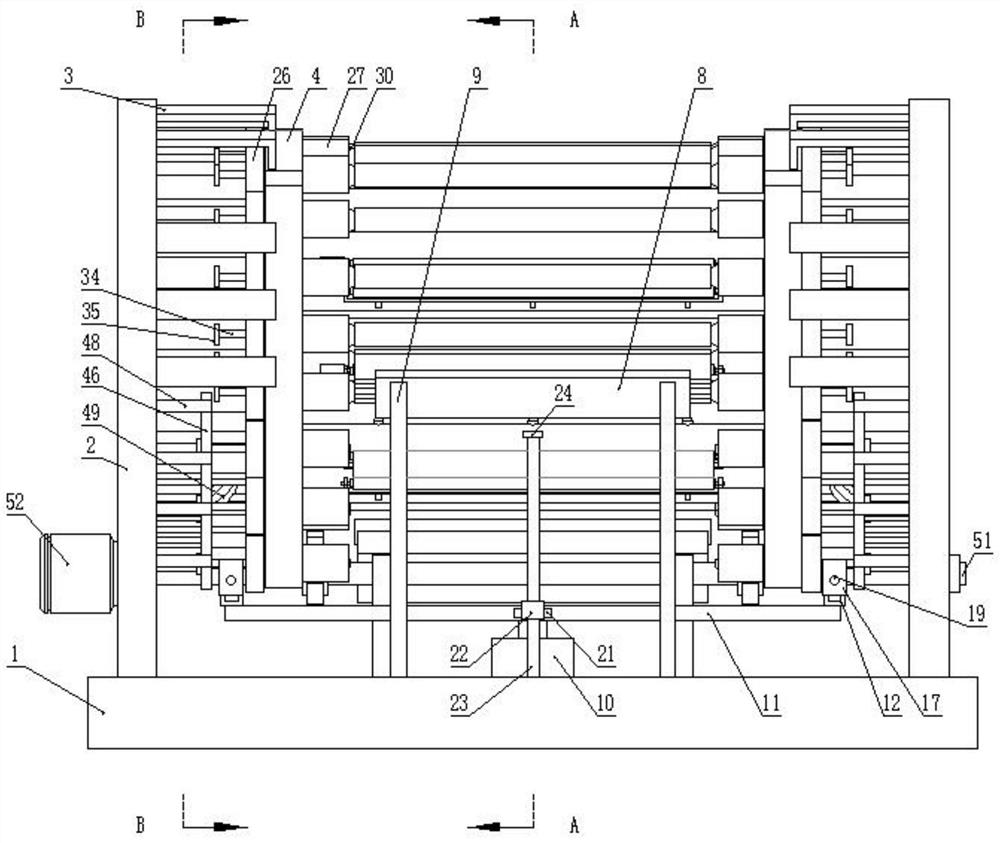

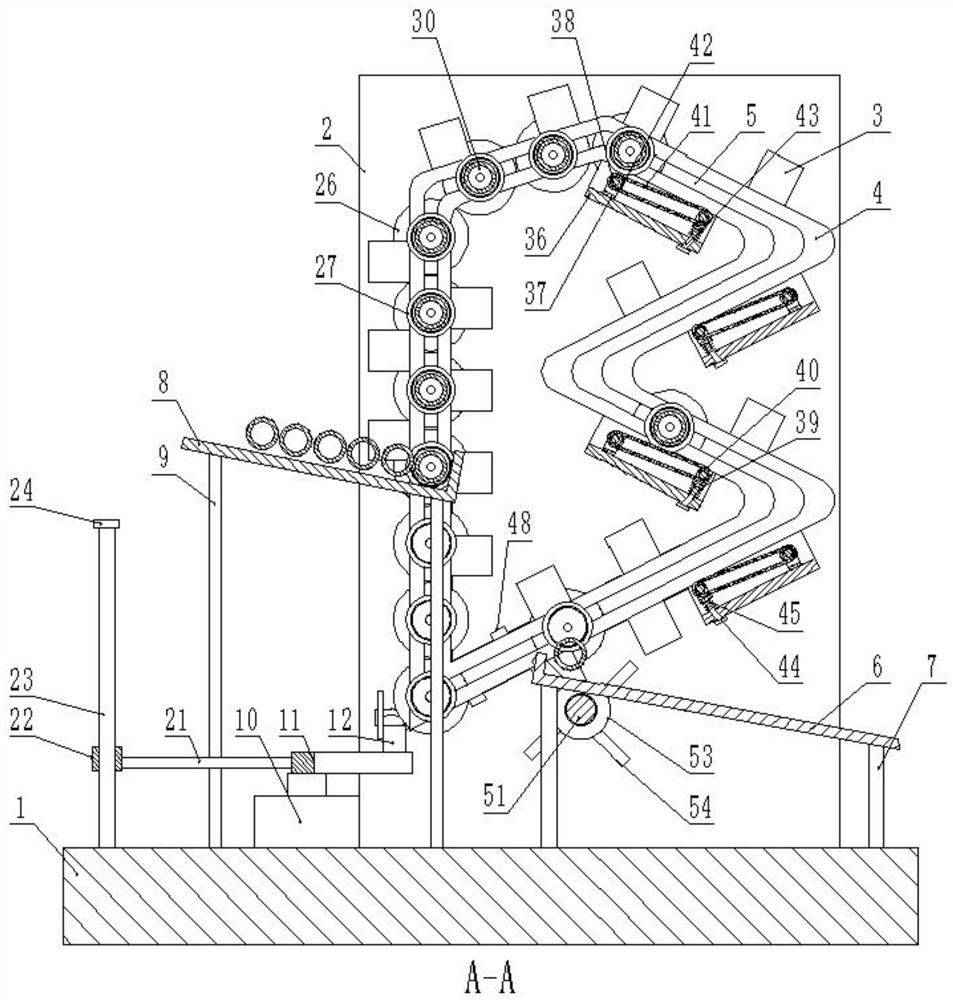

[0019] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, a high-efficiency steel pipe derusting device based on building construction includes a base 1, and mounting plates 2 are symmetrically fixed at both ends of the top surface of the base 1, and a first motor is fixedly installed on the side wall of one mounting plate 2 52. On the opposite side walls of the two mounting plates 2, guide rails 4 are fixed symmetrically through several L-shaped fixing plates 3. The guide rails 4 are in the shape of B, and guide rails 5 are provided on the side walls of the guide rails 4, so that Described guide rail 4 is made up of vertical guide rail 4-1, serpentine guide rail 4-2, upper oblique guide rail 4-3 and lower oblique guide rail 4-4, and described serpentine guide rail 4-2 bottom and verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com