Heating and infrared anti-reflection type structural member, as well as machining method and application thereof

A technology of infrared antireflection and structural parts, applied in ohmic resistance heating parts, electric heating devices, electrical components, etc., can solve problems such as affecting the uniformity of resistance wire heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

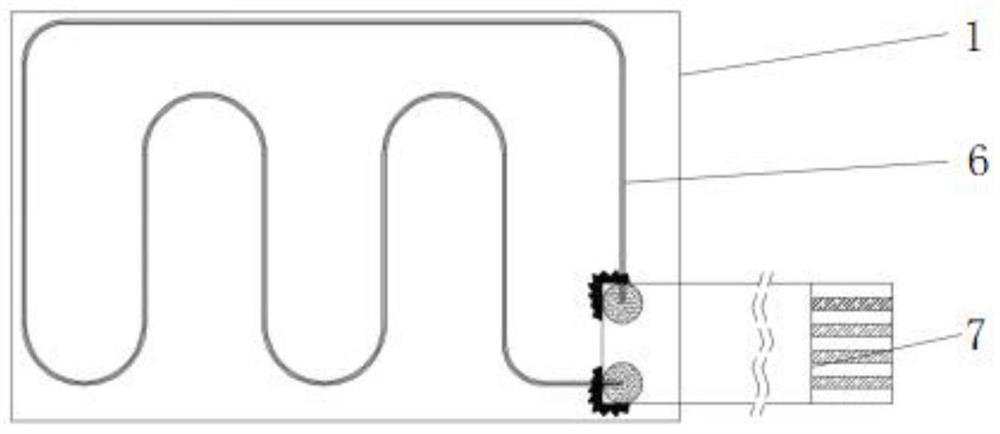

[0052] Such as figure 1 with figure 2 As shown, the structural member includes a base material layer 1 , a functional layer 2 , an infrared anti-reflection layer 3 , a waterproof layer 4 and a hardened strengthening layer 8 .

[0053]The base material layer 1 is injection-molded with infrared light-transmitting plastic, and the inner surface of the base material layer 1 can be made into a mirror effect to improve the transmittance of light waves. The functional layer 2 covers the surface of the substrate layer 1, and is used to heat the structure and transmit infrared light. The functional layer 2 includes a light-transmitting layer and a heating element fixed on the surface of the light-transmitting layer. The heating element consists of a positive lead and The negative pin is connected to the power supply after leading out the light-transmitting layer.

[0054] Among them, the light-transmitting layer can choose ITO conductive film 5, and the ITO conductive film 5 is plat...

Embodiment 2

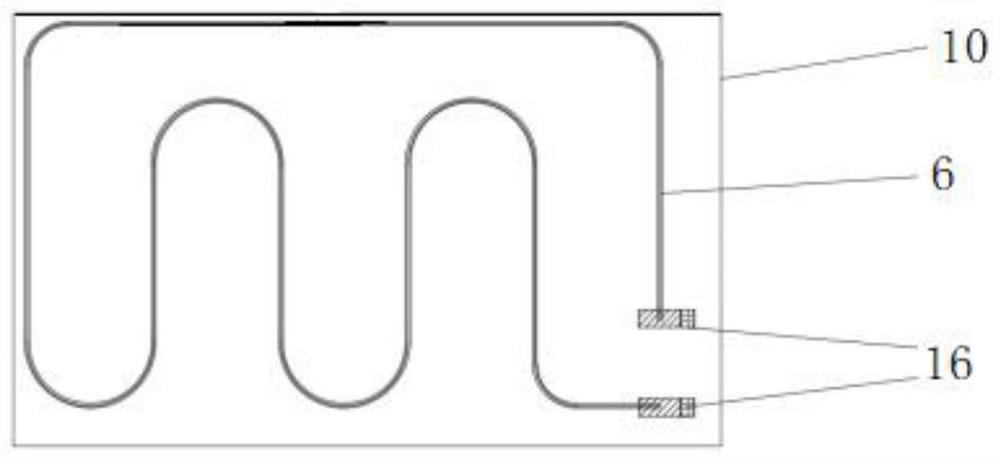

[0067] Such as image 3 with Figure 4 As shown, the structural member includes a base material layer 1 , a functional layer 2 , an infrared anti-reflection layer 3 , a waterproof layer 4 and a hardened strengthening layer 8 .

[0068] The base material layer 1 is injection-molded with light-transmitting plastic, and the inner surface of the base material layer 1 can be made into a mirror effect to improve the transmittance of light waves.

[0069] The functional layer 2 covers the outer surface of the substrate layer 1, and is used to heat the structural parts and transmit infrared light. The functional layer 2 includes a light-transmitting layer and a heating element fixed on the surface of the light-transmitting layer. The heating element is connected by the positive lead Connect the power supply after leading out the light-transmitting layer with the negative pin. The heating element is a resistance wire applied to the light transmissive layer.

[0070] The light-transm...

Embodiment 3

[0083] The difference between this structural member and Embodiment 1 lies in the structure of the functional layer.

[0084] Such as Figure 5 As shown, the light-transmitting layer of the present embodiment is an ITO conductive film 5; the heating element is a graphene film 11, and the sheet-shaped graphene film 11 is provided with an insulating line 12, and the graphene film 11 is divided into the second by the insulating line 12. A conductive region 13 and a second conductive region 14, the first conductive region 13 and the second conductive region 14 are respectively connected to the positive pole and the negative pole of the power supply. The insulated wire 12 has a straight hollow shape, which can be processed by laser engraving or etching, or the first conductive region 13 and the second conductive region 14 can be pasted on the light-transmitting layer with conductive glue at intervals.

[0085] Graphene film 11 has good electrical and thermal conductivity, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com