Detachable three-electrode battery testing device and assembling method thereof

A battery testing, three-electrode technology, applied in the direction of measuring device, measuring device casing, measuring resistance/reactance/impedance, etc., can solve problems such as poor sealing performance, leakage, and inability to meet battery analysis research and performance testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

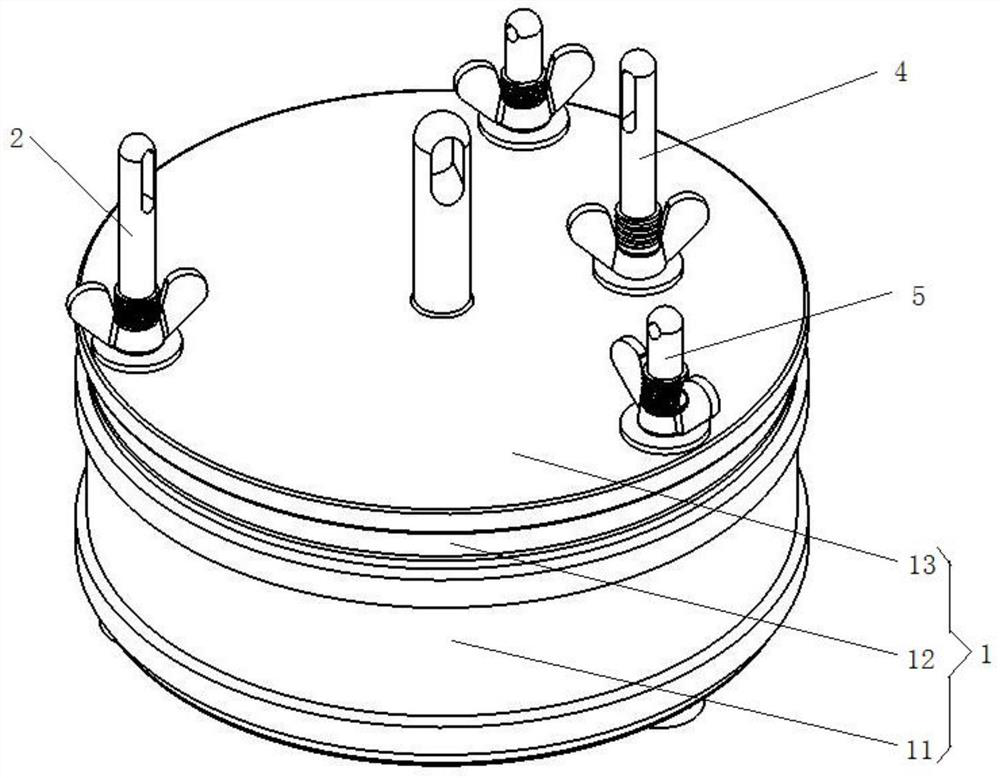

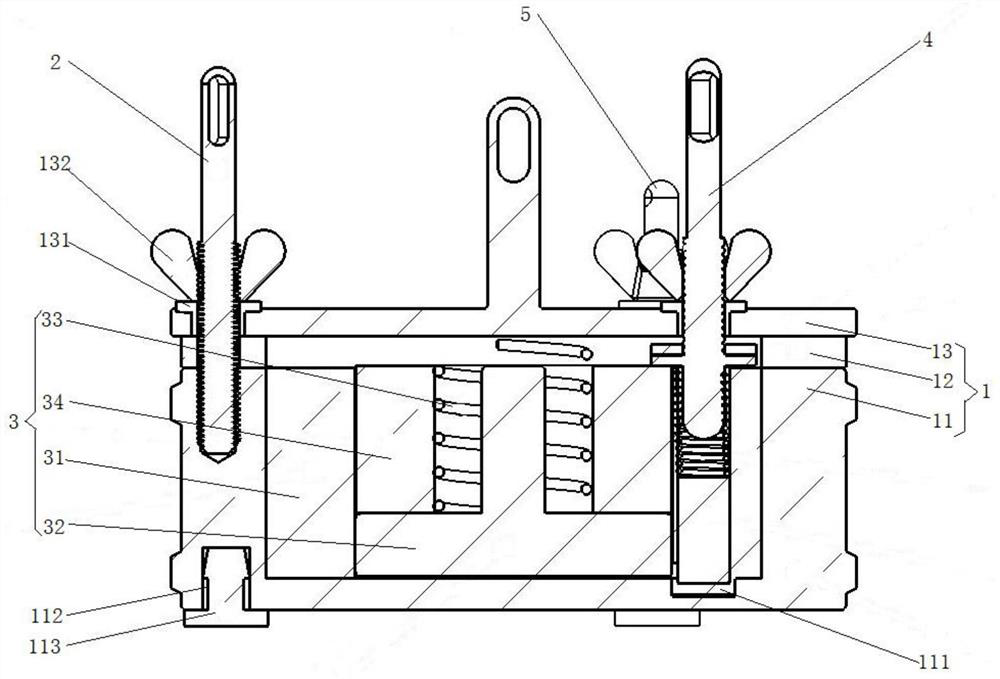

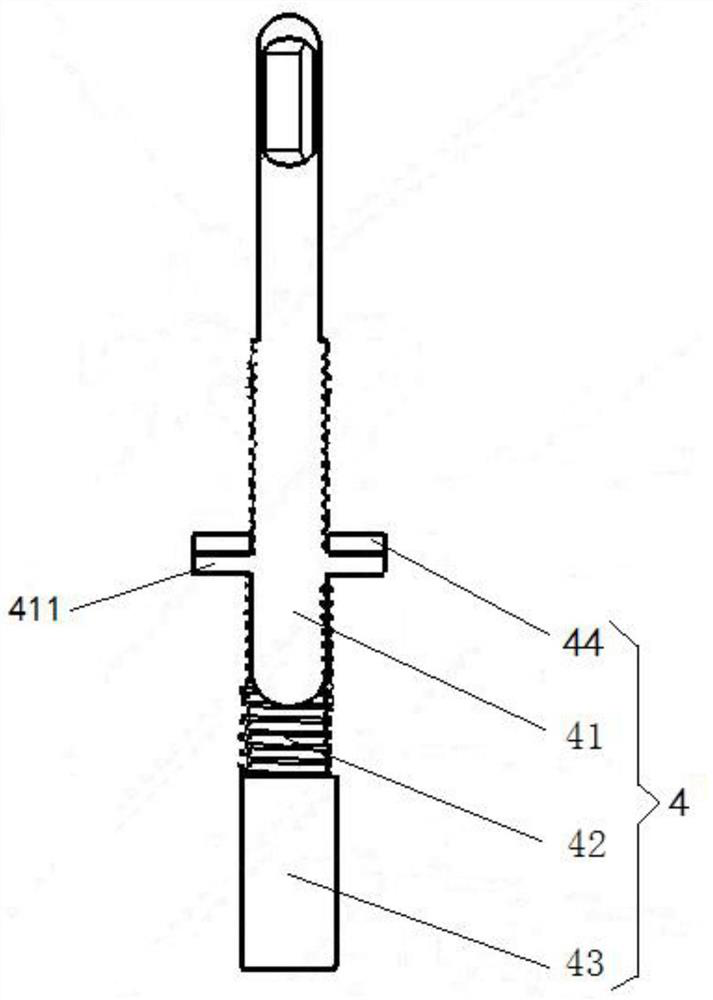

[0046] refer to Figure 1-4 A detachable three-electrode battery test device is shown, including: a housing 1, a wire screw 2, an extrusion assembly 3, a reference electrode assembly 4, and a plurality of fastening screws 5, wherein the housing 1 includes a base 11, a second A sealing ring 12 and an upper cover 13; the bottom of the cavity of the base 11 is provided with a positioning groove 111, and the bottom end of the base 11 is provided with a second non-through hole 112; the second non-through hole 112 is provided with a foot pad 113, and the foot pad 113 It is a tapered buckle-type rubber plug with a plug, made of rubber, polytetrafluoroethylene, silica gel or plastic, etc.; the upper cover 13 is detachably connected to the top of the base 11; the first sealing ring 12 is circular, with a thickness of 1 -6mm, the material is rubber, polytetrafluoroethylene, silica gel or plastic, etc., and a through hole is arranged on it. The first sealing ring 12 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com