Vortex ring exciter based on pressure loss control

An exciter and vortex ring technology, applied in the field of vortex ring exciters, can solve the problems of high impact and noise, the ventilation volume of the vortex ring cannot meet the requirements, and the performance of the motor cannot be maximized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

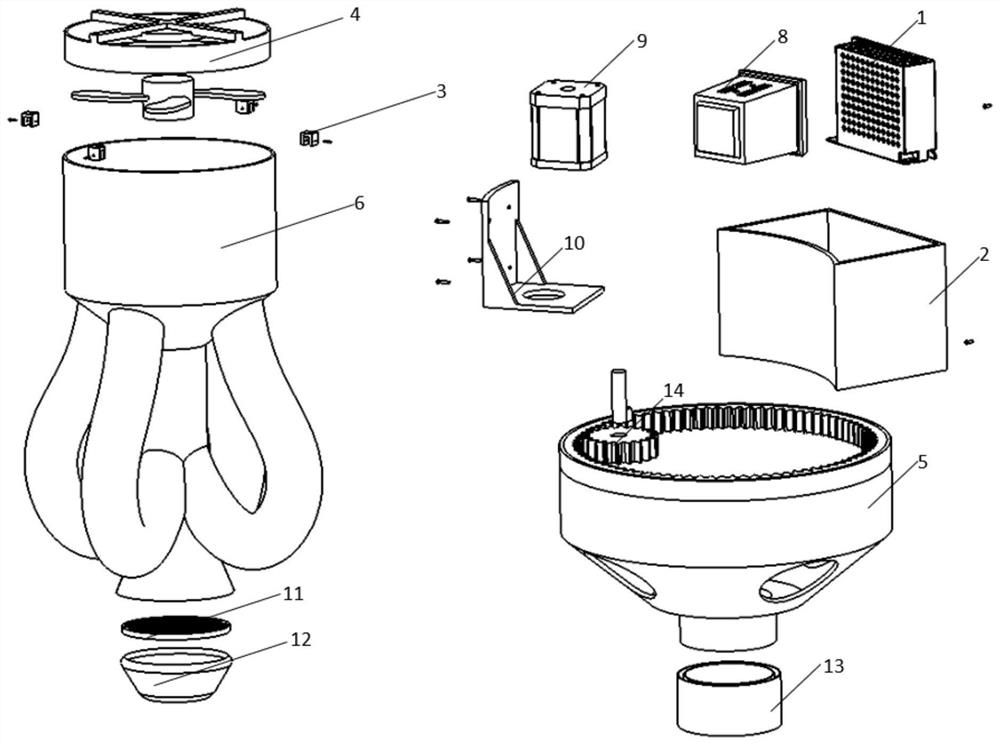

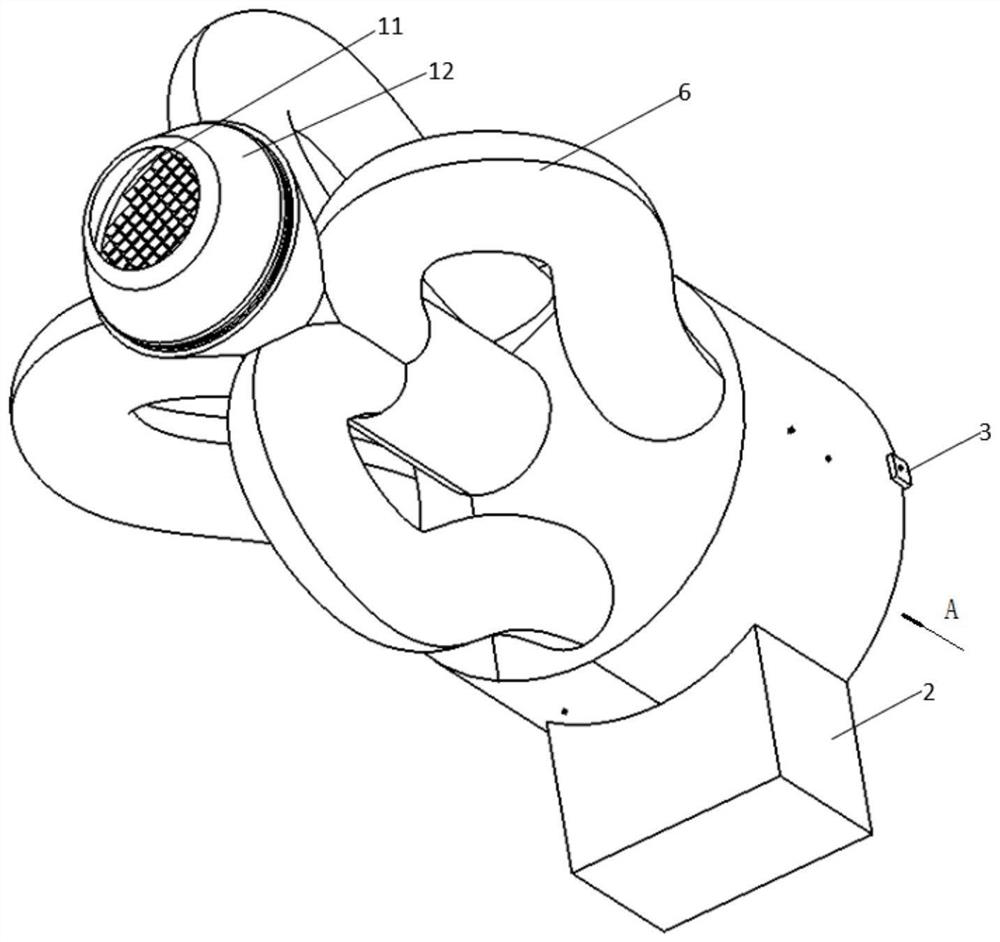

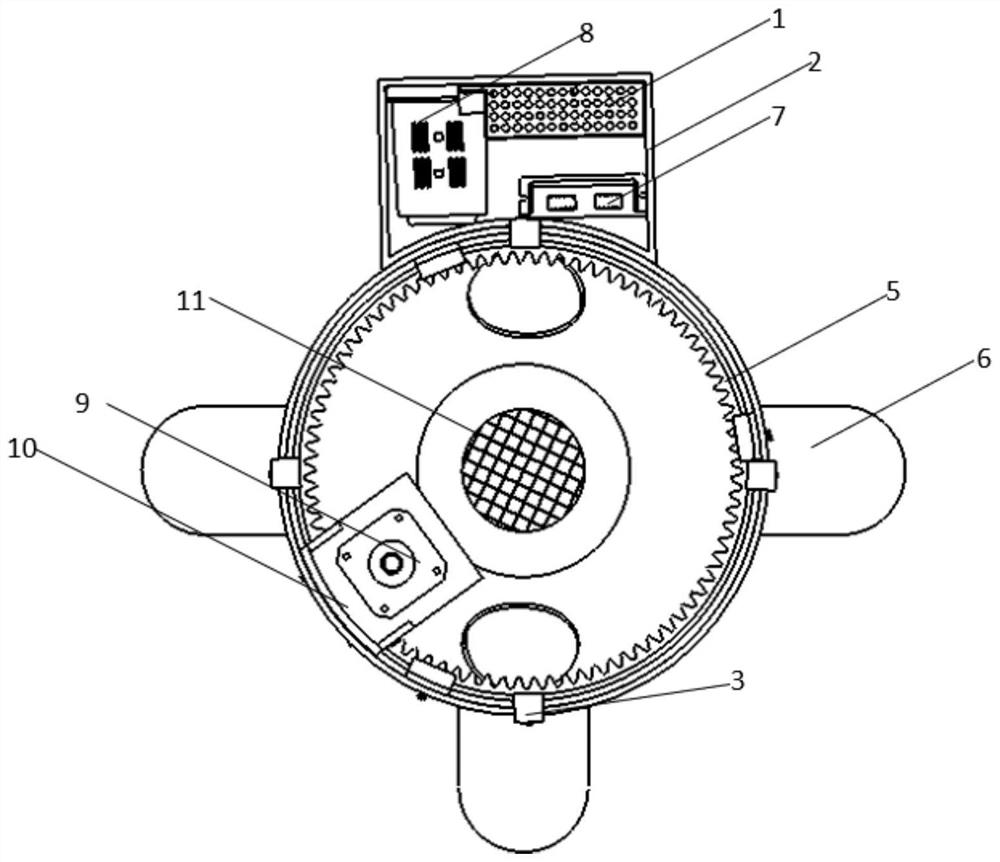

[0028] refer to Figure 1 to Figure 8 As shown, the vortex ring exciter based on pressure loss control in an embodiment provided by the present invention includes an axial flow fan 4, a main air supply duct 15, a interceptor, a tapering nozzle 12 and a plurality of hedging and intercepting ducts 6, and the shaft The flow fan 4 is arranged at the inlet end of the main air supply duct 15, the tapered nozzle 12 is arranged at the outlet end of the main air supply duct 15, and a plurality of hedging cut-off pipes 6 are evenly distributed along the circumference of the main air supply pipe 15, and the hedging cut-off pipes 6 The inlet of the inlet is communicated with the upper inner cavity of the main air supply duct 15, and the outlet of the hedging cut-off pipeline 6 is communicated with the lower inner cavity of the main air supply duct 15, and the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com