Bidirectional diaphragm pump without distributing valve

A technology for diaphragm pumps and flow distribution valves, which is applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., and can solve problems such as easy crystallization, increased difficulty of development work, and increased system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

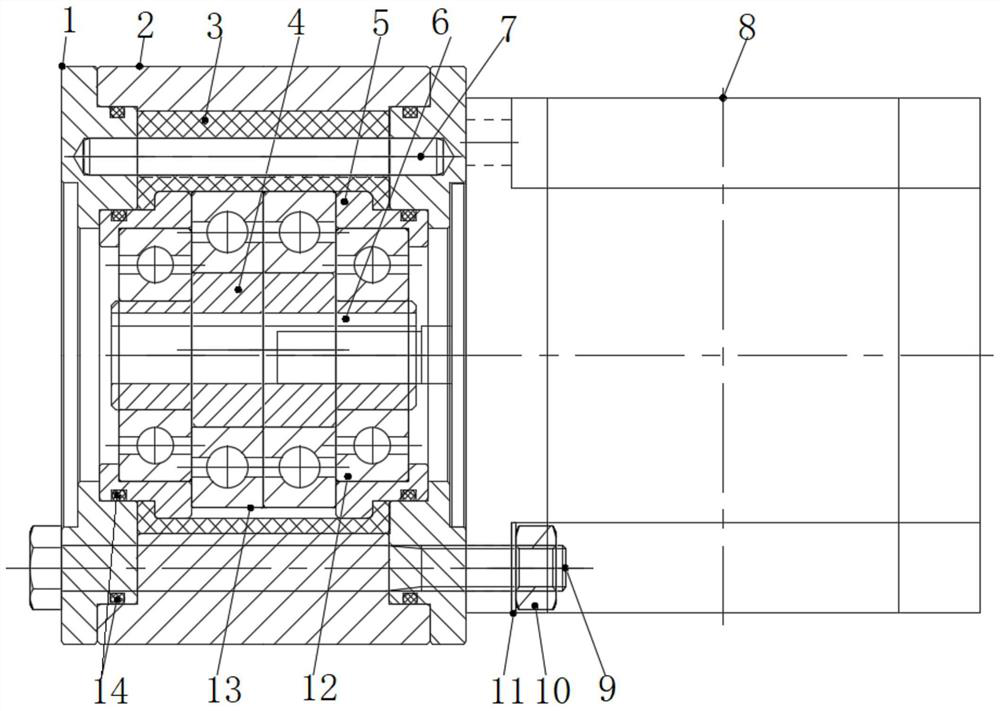

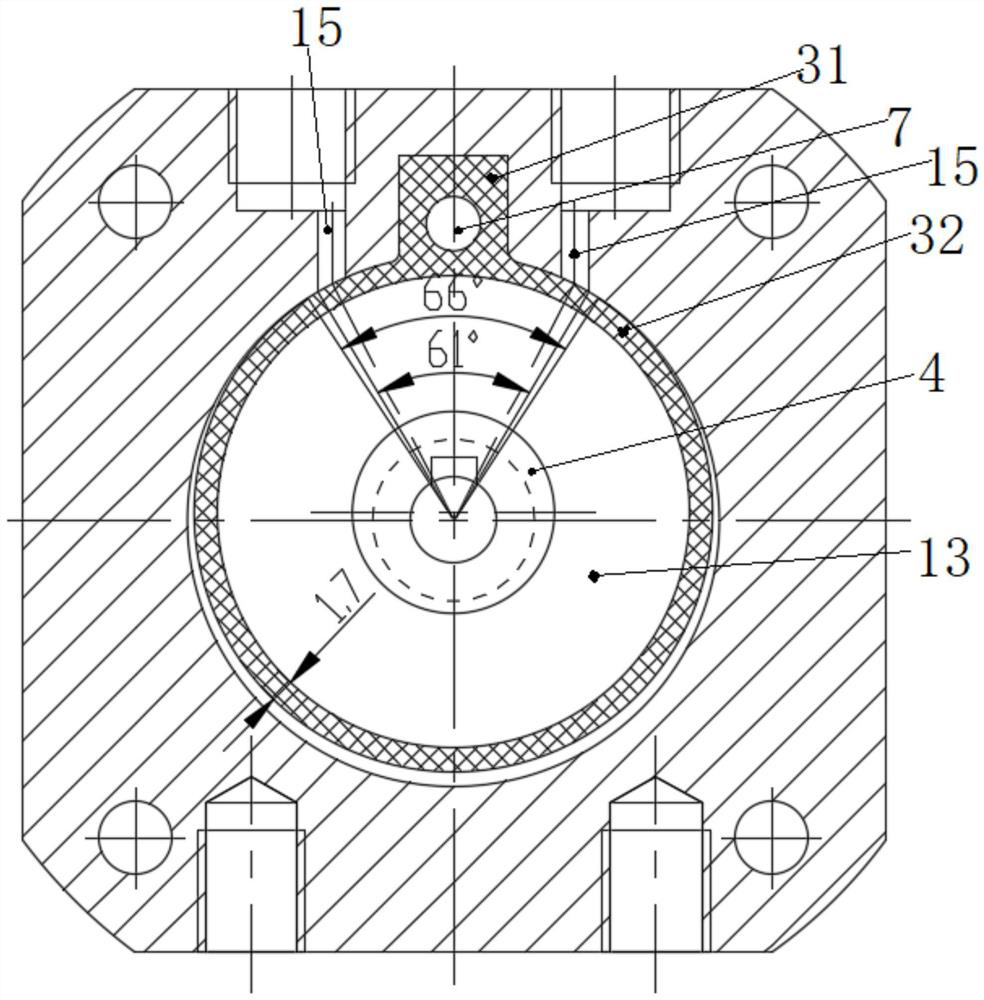

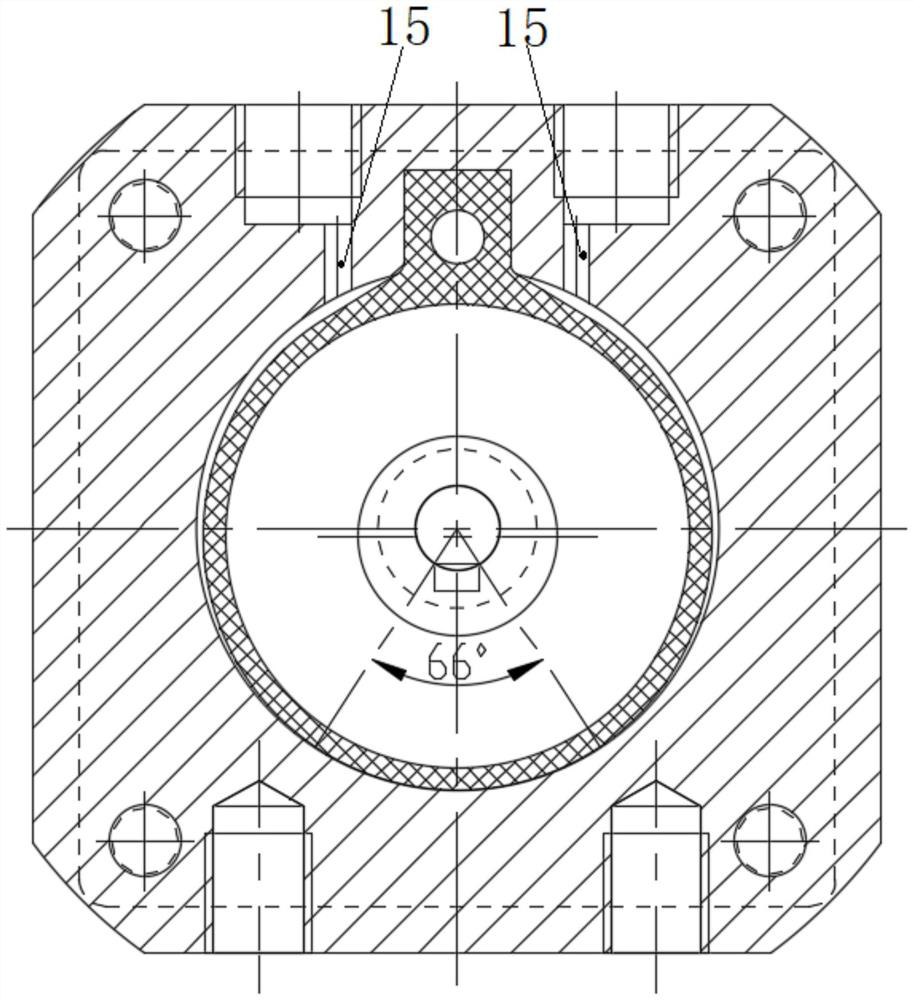

[0023] Such as Figure 1 to Figure 3 As shown, a two-way diaphragm pump without flow distribution valve includes a housing and a motor 8 installed together. Two flow channels 15 are opened on the outer wall of the housing, and an eccentric shaft 4 driven by the motor 8 is arranged inside. Diaphragm 3 for grinding materials, the eccentric section of eccentric shaft 4 is covered with extrusion bearing 13, the two ends of diaphragm 3 are axially positioned and sealed with the housing, and the radial side of diaphragm 3 is an anti-skid protrusion 31 connected with the housing. The other side is the ring sleeve 32 that is set on the extrusion bearing 13. The two flow channels 15 respectively extend to both sides of the anti-slip protrusion 31 on the inner wall of the housing and are isolated by the ring sleeve 32 and are always disconnected. One side is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com