Full-section hydraulic blasting demolition method for urban viaduct

A technology for hydraulic blasting and viaducts, which is applied in the directions of bridges, bridge construction, bridge maintenance, etc., and can solve problems such as potential safety hazards, larger vibrations when the bridge body collapses and touches the ground, and the weight of box girder increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the technical solutions in the embodiments of the present invention will be described in contemplation in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are merely embodiments of the invention, and preferred embodiments of the present invention are given in the accompanying drawings. The present invention can be accomplished in many different forms, and is not limited to the embodiments described herein, and for the purpose of providing these embodiments, the understanding of the disclosure of the present invention is more thoroughly comprehensively.

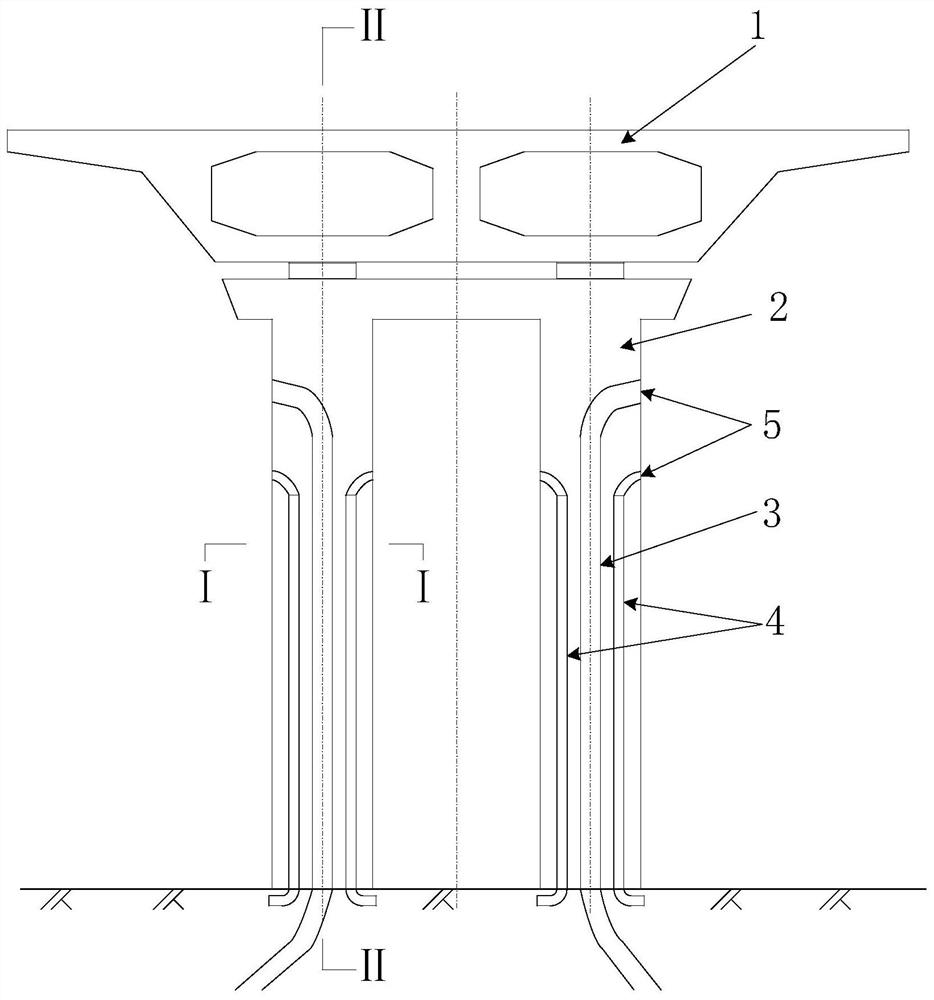

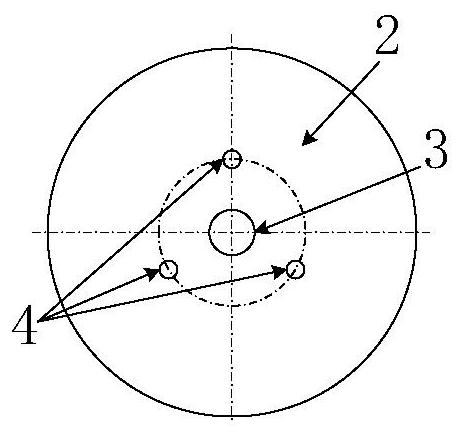

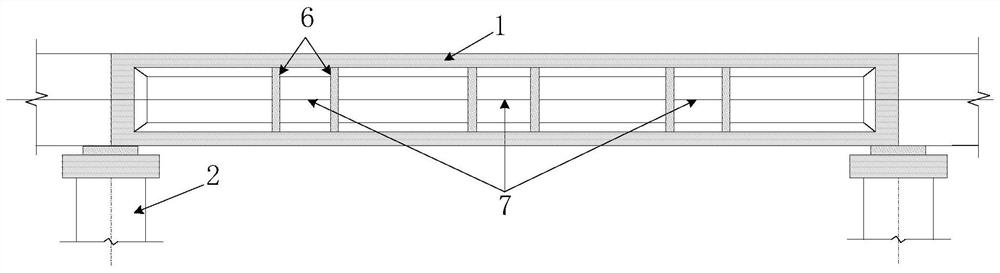

[0031] See Figure 1-5 As shown, the urban elevated bridge full-section water pressure blasting removal method of the present invention includes the steps of:

[0032] S1: In the design phase of the city viaduct, the built-in reserve hole design and groove design are added; four reserved holes in each of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com