Method for constructing high-stability perovskite quantum dot illuminant through in-situ polymerization

A technology of quantum dot luminescence and in-situ polymerization, applied in luminescent materials, chemical instruments and methods, nano-optics, etc., can solve the problems of difficulty in making large volumes and high preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

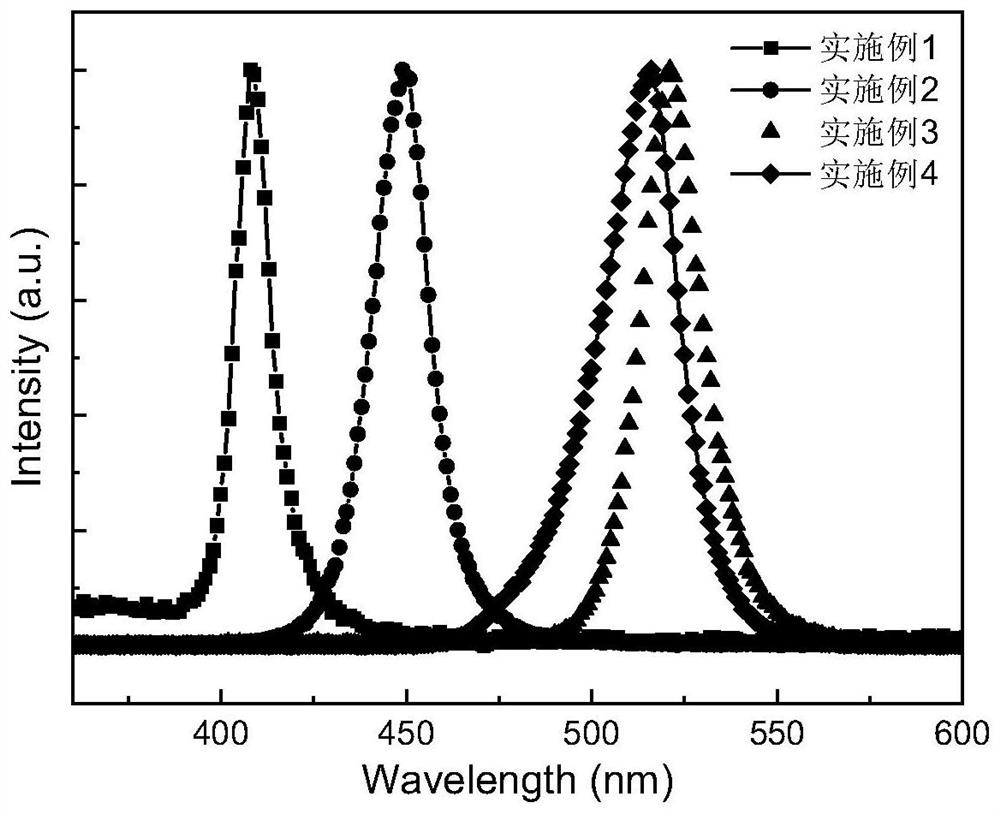

Embodiment 1

[0023] 1) Preparation of perovskite quantum dot A(Cs) precursor: Take 2.498g of cesium stearate and dissolve in 21.8763g of oleic acid and 30.02g of octadecene, stir in a glove box at 150°C until completely dissolved, weigh 1.5g for later use .

[0024] 2) 10g lauryl methacrylate (LMA), 4.05g oleic acid, 3.6595g oleylamine, 0.297g PbBr 2 and 0.225g PbCl 2 Add it into a 100mL flask and stir, vacuumize and heat at 120°C under the protection of argon, then rapidly raise the temperature to 180°C to obtain a Pb precursor, heat 1.5g of the Cs precursor solution to 180°C and inject it into the Pb precursor, react Immediately after 5S, ice bath was carried out to obtain the stock solution of quantum dots emitting purple light.

[0025] 3) 9.44g methyl methacrylate (MMA) and 0.05g dibenzoyl peroxide (BPO) were stirred at 85°C for 13 minutes. When a large number of bubbles appeared in the solution, immediately take out the water bath and lower the temperature to below 40°C to obtain a...

Embodiment 2

[0028] 1) Preparation of perovskite quantum dot Cs precursor: 2.498g of cesium stearate was dissolved in 21.8763g of oleic acid and 30.02g of octadecene, stirred in a glove box at 150°C until completely dissolved, and 1.5g was weighed for later use.

[0029] 2) 10g lauryl methacrylate (LMA), 4.05g oleic acid, 3.6595g oleylamine, 0.4455g PbBr 2 and 0.1125g PbCl 2 Add it into a 100mL flask and stir, evacuate and heat at 120°C under the protection of argon, and then rapidly raise the temperature to 190°C to obtain a Pb precursor. Heat 1.5g of the Cs precursor solution to 180°C and inject it into the Pb precursor. Immediately after 5S, ice bath was carried out to obtain the stock solution of quantum dots emitting blue light.

[0030] 3) 9.44g methyl methacrylate (MMA) and 0.05g dibenzoyl peroxide (BPO) were stirred at 85°C for 13 minutes. When a large number of bubbles appeared in the solution, immediately take out the water bath and lower the temperature to below 40°C to obtain ...

Embodiment 3

[0033] 1) Preparation of Cs precursor: 2.498g of cesium stearate was dissolved in 21.8763g of oleic acid and 30.02g of octadecene, stirred in a glove box at 150°C until completely dissolved, and 1.8g was weighed for later use.

[0034] 2) 10g lauryl methacrylate (LMA), 4.05g oleic acid, 3.6595g oleylamine, 0.594g PbBr 2 Add it into a 100mL flask and stir, vacuumize and heat at 120°C under the protection of argon, then rapidly raise the temperature to 180°C to obtain a Pb precursor, heat 1.8g of the Cs precursor solution to 180°C and inject it into the Pb precursor, react Immediately after 5S, ice bath was carried out to obtain the stock solution of quantum dots emitting green light.

[0035] 3) 9.44g methyl methacrylate (MMA) and 0.05g dibenzoyl peroxide (BPO) were stirred at 85°C for 13 minutes. When a large number of bubbles appeared in the solution, immediately take out the water bath and lower the temperature to below 40°C to obtain a polymer polymer prepolymerization sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com