Efficient photocatalytic nano material with memory effect, preparation method of efficient photocatalytic nano material and air purifier

A nanomaterial and photocatalytic technology, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve the problem of losing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

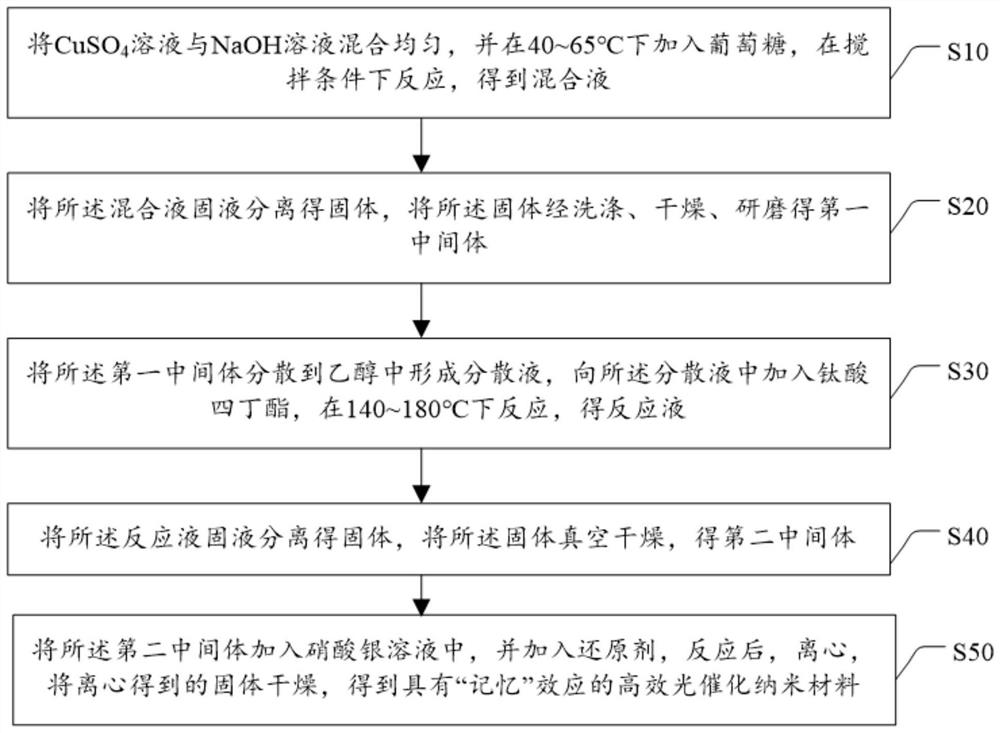

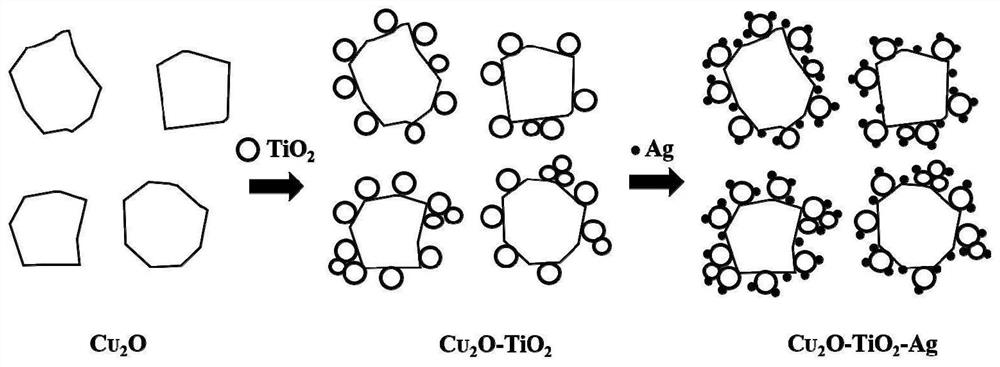

[0044] The present invention further proposes a method for preparing a high-efficiency photocatalytic nanomaterial with a "memory" effect as described above, please refer to figure 1 , the preparation method of the high-efficiency photocatalytic nanomaterial with "memory" effect proposed by the present invention, comprises the following steps:

[0045] S10, the CuSO 4 The solution is uniformly mixed with the NaOH solution, and glucose is added at 40-65° C. to react under stirring conditions to obtain a mixed solution.

[0046] In this step, Cu is mainly prepared 2 O, the main reaction equation is as follows:

[0047] 2CuSO 4 +4NaOH+C 6 h 12 o 6 → Cu 2 O+2Na 2 SO4+C 6 h 12 o 7 +2H 2 o

[0048] Glucose, as a reducing agent, is oxidized to carboxylic acid, and copper sulfate, as an oxidant, is reduced to cuprous oxide.

[0049] In this step, the ratio of copper sulfate, sodium hydroxide and glucose is not limited by the present invention. Preferably, the CuSO 4 The...

Embodiment 1

[0080] (1) CuSO 4 solution mixed with NaOH solution, CuSO 4 The amount of the substance of NaOH is 0.02mol, the amount of the substance of NaOH is 0.03mol, and 0.04mol of glucose is added at 65°C, and the reaction is carried out for 2.5h under stirring conditions to obtain a mixed solution;

[0081] (2) Centrifuge the mixed solution to obtain a solid, wash the solid with deionized water, and then wash with ethanol, then vacuum-dry at 65° C. for 12 hours, and grind to obtain the first intermediate;

[0082] (3) Disperse the first intermediate into 20 mL of ethanol to form a dispersion liquid, add 0.04 mmol tetrabutyl titanate to the dispersion liquid, stir well to obtain a mixture, add 2 mL of ethanol aqueous solution to the mixture, and ethanol aqueous solution , the mass ratio of ethanol to water is 4, after stirring for 1.5h, react at 180°C for 10h to obtain the reaction solution;

[0083] (4) separating the solid and liquid from the reaction solution to obtain a solid, an...

Embodiment 2

[0087] (1) CuSO 4 solution mixed with NaOH solution, CuSO 4 The amount of the substance of NaOH is 0.02mol, the amount of the substance of NaOH is 0.03mol, and 0.04mol of glucose is added at 65°C, and the reaction is carried out for 2.5h under stirring conditions to obtain a mixed solution;

[0088] (2) Centrifuge the mixed solution to obtain a solid, wash the solid with deionized water, and then wash with ethanol, then vacuum-dry at 65° C. for 12 hours, and grind to obtain the first intermediate;

[0089] (3) Disperse the first intermediate into 20 mL of ethanol to form a dispersion liquid, add 0.06 mmol tetrabutyl titanate to the dispersion liquid, stir well to obtain a mixture, add 2 mL of ethanol aqueous solution to the mixture, and ethanol aqueous solution , the mass ratio of ethanol to water is 4, after stirring for 1.5h, react at 180°C for 10h to obtain the reaction solution;

[0090] (4) separating the solid and liquid from the reaction solution to obtain a solid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com