Weeding preparation and application thereof

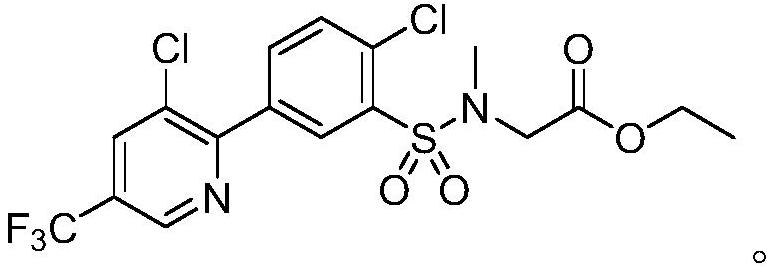

A preparation and dispersant technology, which is applied in the field of 2--N-methylbenzenesulfonamide) ethyl acetate herbicide preparation and herbicide composition for paddy fields, can solve the problem of large environmental pollution and the biological activity of herbicide active components Problems such as unsatisfactory performance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

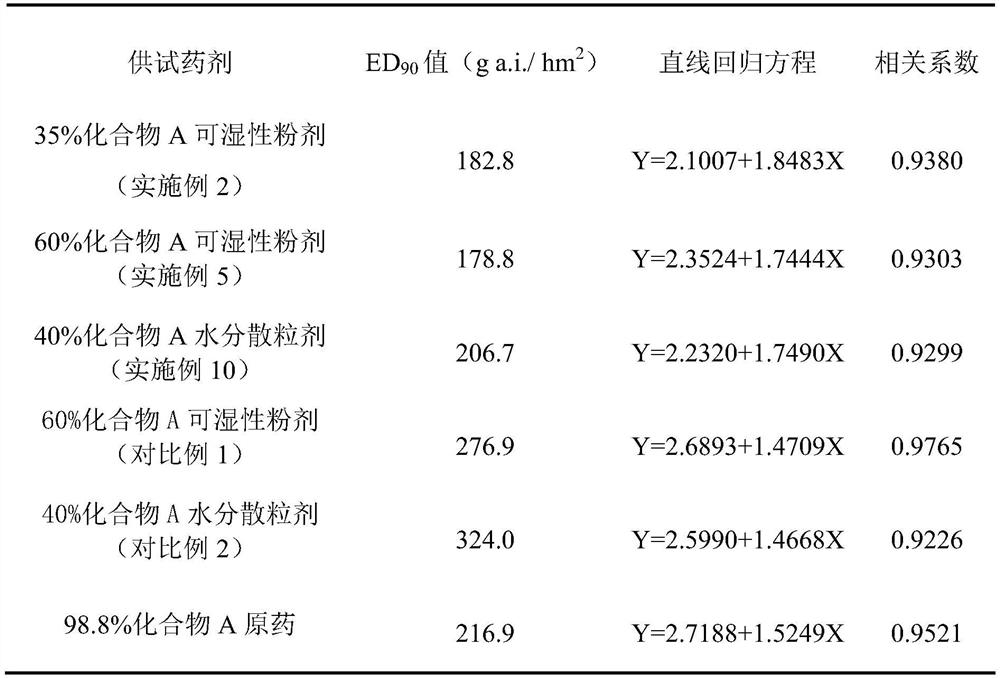

Examples

Embodiment 1、75

[0041] The preparation of embodiment 1,75% compound A wettable powder

[0042]According to the formulation requirements, 75 parts of compound A, 1.5 parts of Morwet EFW, 4 parts of Supragil MNS / 90, 4 parts of sodium salt of alkylnaphthalenesulfonic acid polycondensate, 3 parts of alkylnaphthalenesulfonate formaldehyde condensate, 5 parts of white carbon Black and diatomaceous earth are supplemented to 100% and fully mixed, and pulverized by an ultrafine pulverizer to obtain a 75% compound A wettable powder. Measurement results of physical properties: active component content, 75.2%; fineness (through 45μm standard sieve) 99.5%; suspension rate, 92.9%; wetting time, 30s; thermal storage (54±2°C / 14d): content, 74.5 %, fineness (through 45 μm standard sieve) 98.1%; suspension rate, 90.5%; wetting time, 35s.

Embodiment 2、35

[0043] The preparation of embodiment 2,35% compound A wettable powder

[0044] According to the formulation requirements, 35 parts of compound A, 2 parts of sodium lauryl sulfate, 4 parts of Supragil MNS / 90, 3 parts of polycarboxylate dispersant GY-D02, 4 parts of sodium methylene naphthalene sulfonate, 4 parts Sodium lignosulfonate, 5 parts of white carbon black, and diatomaceous earth are added to 100% and mixed thoroughly, and pulverized by an ultrafine pulverizer to obtain a 35% compound A wettable powder. Measurement results of physical properties: active component content, 35.1%; fineness (through 45μm standard sieve) 99.8%; suspension rate, 95.3%; wetting time, 15s; thermal storage (54±2°C / 14d): active component Content, 34.6%; fineness (through 45μm standard sieve) 99.1%; suspension rate, 92.5%; wetting time, 15s.

Embodiment 3、60

[0045] The preparation of embodiment 3,60% compound A wettable powder

[0046] According to the formulation requirements, add 60 parts of compound A, 2 parts of wetting agent TENSIOFIX BCZ, 4 parts of dispersant SK-24, 5 parts of polycarboxylate dispersant GY-D02, 5 parts of white carbon black, diatomaceous earth to 100 % fully mixed, after being pulverized by an ultrafine pulverizer, 60% compound A wettable powder was obtained. Measurement results of physical properties: active component content, 60.3%; fineness (through 45μm standard sieve) 99.7%; suspension rate, 93.1%; wetting time, 20s; thermal storage (54±2°C / 14d): active component Content, 59.5%; fineness (through 45μm standard sieve) 98.2%; suspension rate, 91.1%; wetting time, 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com