Method and system for suppressing high-frequency PWM vibration of multiple three-phase permanent magnet synchronous motors

A permanent magnet synchronous motor, vibration suppression technology, applied in the direction of suppressing motor vibration control, control system, AC motor control, etc., can solve the problem of suppressing high-frequency PWM vibration of multiple three-phase permanent magnet synchronous motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

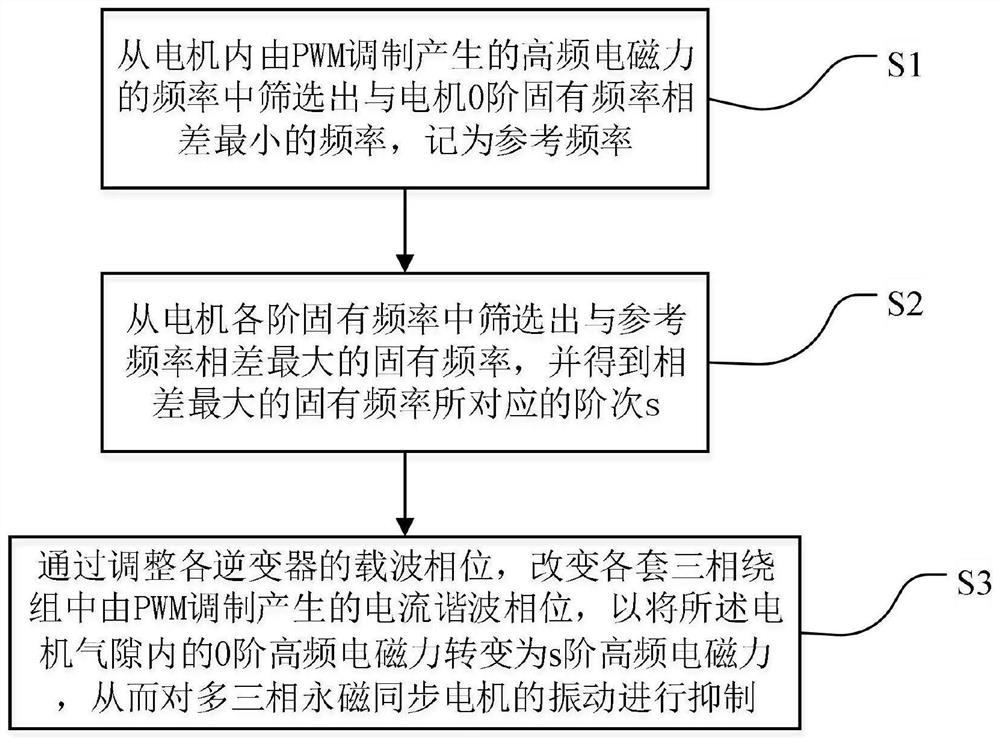

[0042] A multi-three-phase permanent magnet synchronous motor high-frequency PWM vibration suppression method;

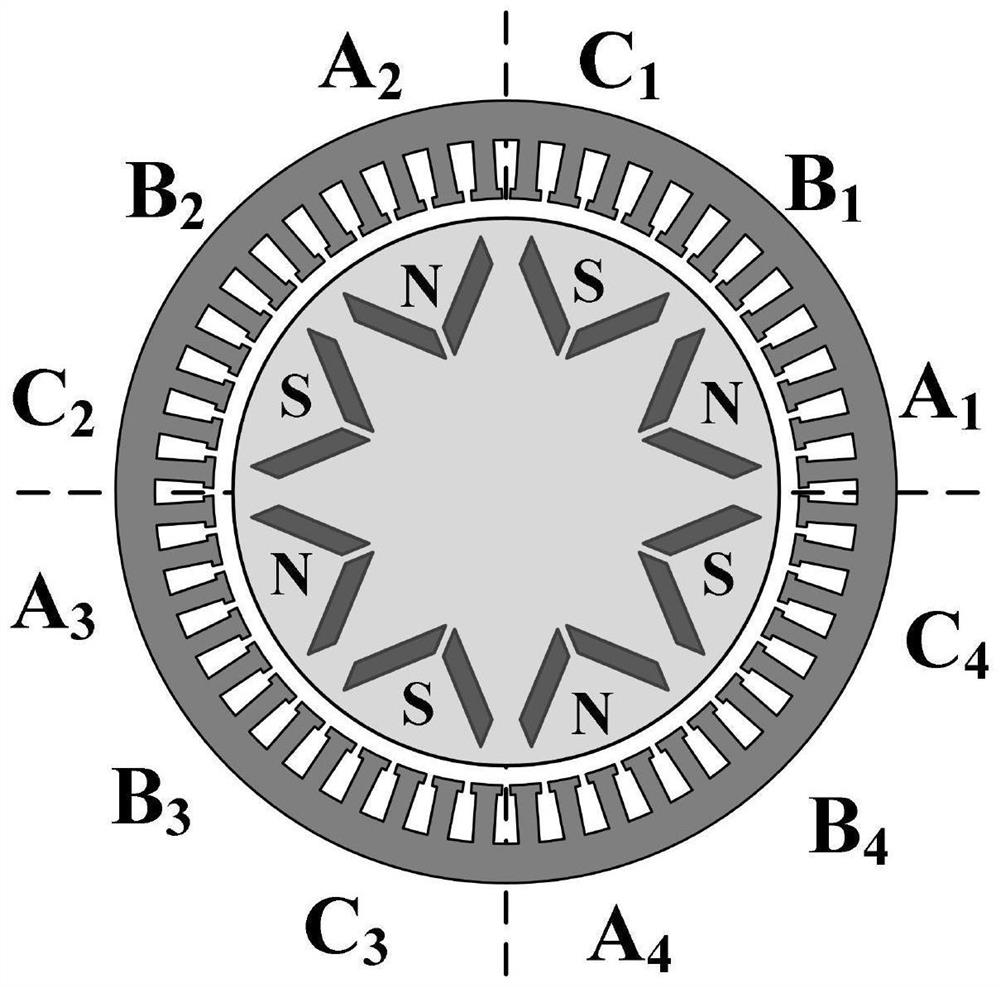

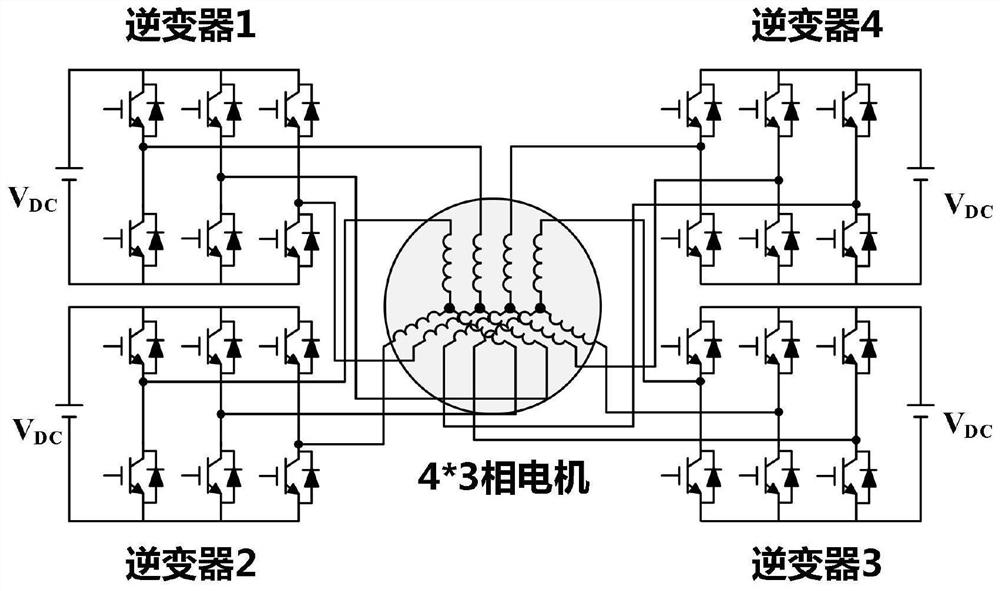

[0043] Among them, the multi-three-phase permanent magnet synchronous motor includes: N sets of three-phase windings; each set of three-phase windings is arranged sequentially along the circumference of the stator; each set of three-phase windings is independently controlled by the corresponding inverter; N is an even number; Each set of three-phase windings is rotationally symmetrical about the center of the stator, and two adjacent sets of three-phase windings are only coupled at the stator teeth between them; each set of three-phase windings is connected to the corresponding inverter, and each inverter The inverters are independent of each other in control, and are controlled by PWM modulation algorithm;

[0044] The invention considers the vibration generated by the high-frequency radial electromagnetic force acting on the stator, and changes the spatial order o...

Embodiment 2

[0107] A multi-three-phase permanent magnet synchronous motor high-frequency PWM vibration suppression system, including:

[0108] The reference frequency acquisition module is used to select the frequency with the smallest difference from the 0-order natural frequency of the motor from the frequency of the high-frequency electromagnetic force generated by PWM modulation in the motor, and record it as the reference frequency;

[0109] The spatial order acquisition module is used to filter out the natural frequency with the largest difference from the reference frequency from the natural frequencies of each order of the motor, and obtain the order s corresponding to the natural frequency with the largest difference;

[0110] The order transformation control module is used to change the current harmonic phase generated by PWM modulation in each set of three-phase windings by adjusting the carrier phase of each inverter, so as to transform the 0-order high-frequency electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com