High-voltage contactor

A technology of high-voltage contactors and high-voltage contacts, which is applied in the direction of relays, electromagnetic relays, details of electromagnetic relays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

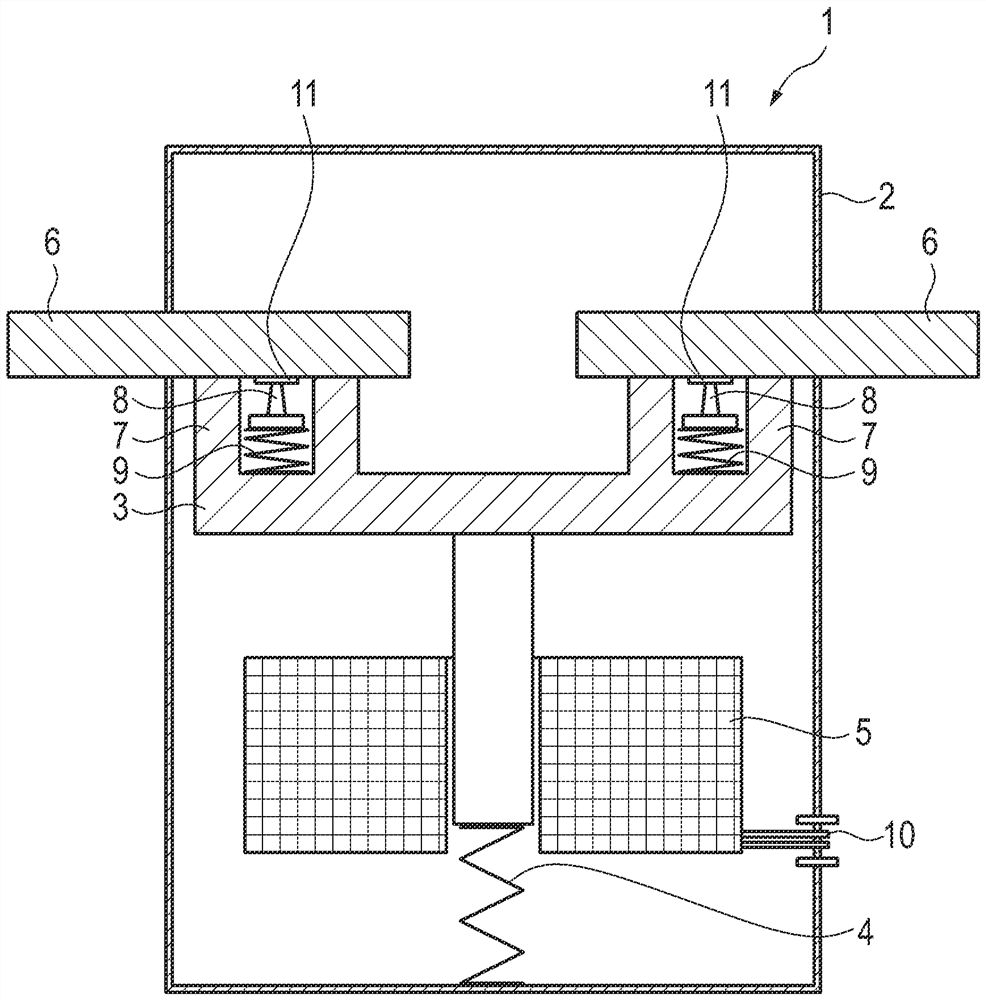

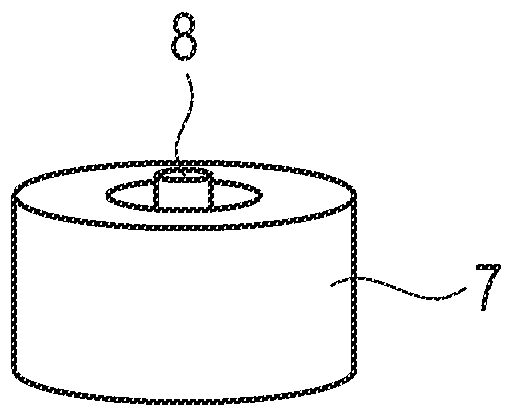

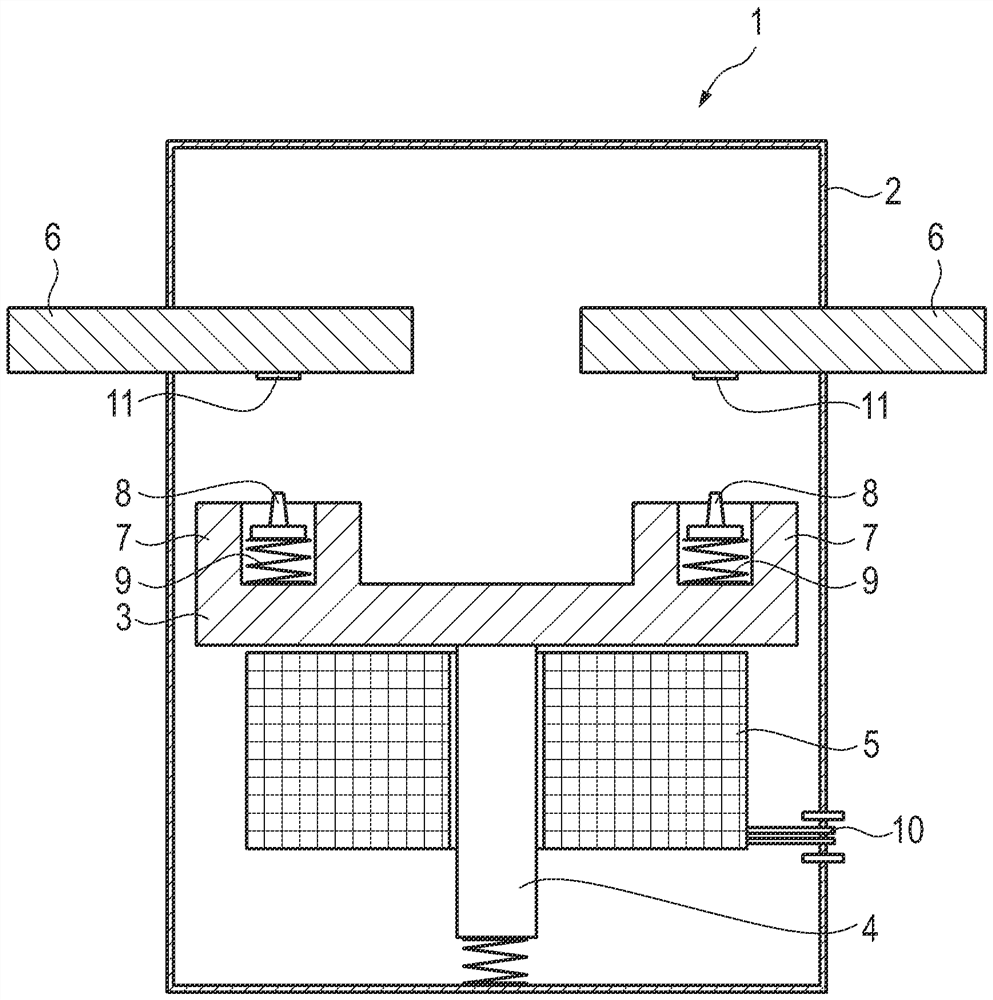

[0019] The high-voltage contactor 1 comprises a housing 2 , a contact bridge 3 , an armature 4 , a coil 5 , two high-voltage contacts 6 , two main contacts 7 and two auxiliary contacts 8 , which are supported on springs 9 . The coil 5 has electrical connections 10 leading out of the housing 2 . The armature 4 is supported elastically. With the spring 9 unloaded, the auxiliary contact 8 protrudes beyond the main contact 7 . Furthermore, the high-voltage contact 6 has a protrusion 11 in each case in the contact region of the auxiliary contact 8 . The auxiliary contact 8 is concentrically surrounded by its main contact 7 , wherein the main contact 7 is of cylindrical design (see figure 2 ). If the high-voltage contactor 1 is now switched from the rest position into the on position by energizing the connection 10 , the armature 4 and the contact bridge 3 are moved upwards. Due to the fact that the auxiliary contacts 8 protrude beyond the main contacts 7 , these two auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com