Variable load control and optimization method for air separation liquefaction device

A technology of liquefaction device and optimization method, applied in design optimization/simulation, special data processing application, geometric CAD, etc., can solve the problems of waste of energy consumption, difficult control of variable load process, gas emission of pipeline network, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

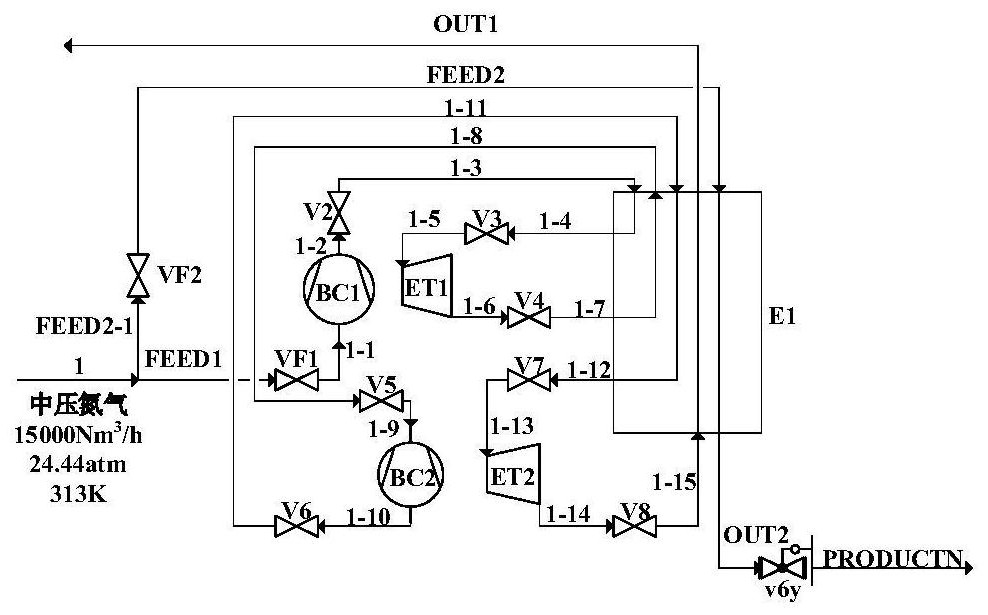

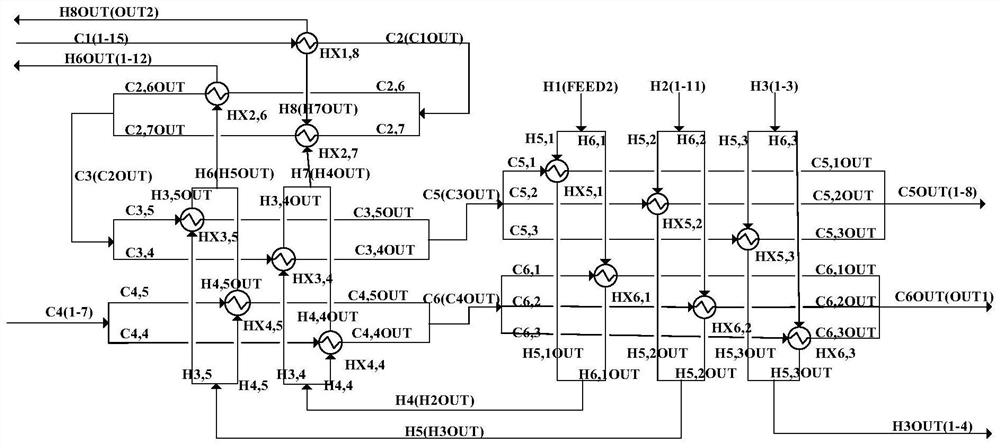

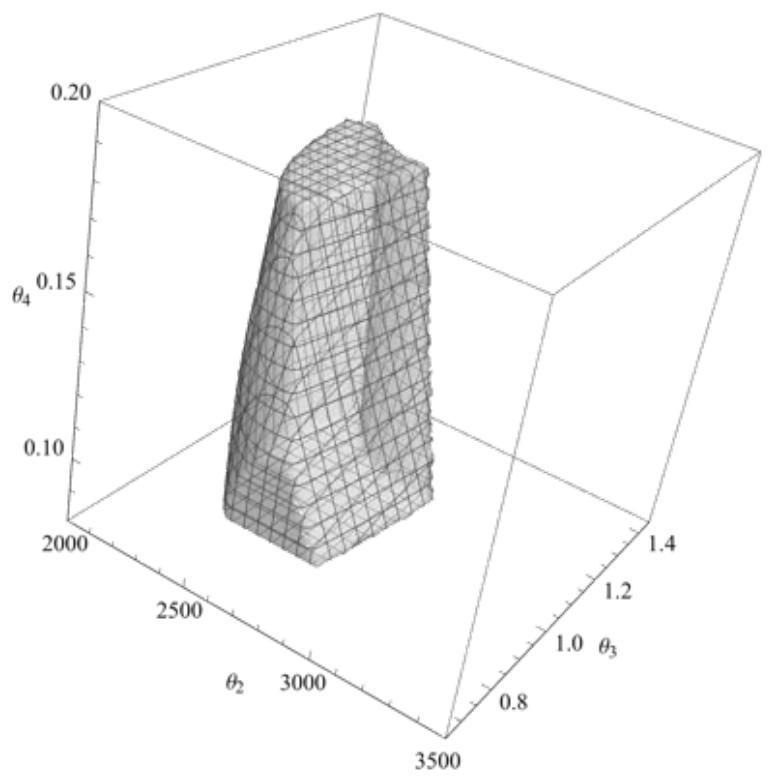

[0071] Taking medium-pressure nitrogen feed at 313K with a pressure of 24.44atm (the pressure fluctuates between 1.6MPa-2.5Mpa) as an example, the operating pressures at the compression end BC1 and BC2 of the high-temperature expander at steady state are 33atm and 14.2atm respectively; The operating pressures of ET1 and ET2 are 10atm and 1.35atm respectively; the temperature of multi-stream heat exchange outlet streams 1-4 is about 200K, and the temperature of 1-12 is about 139K. The total flow of nitrogen from the pipe network is 15000Nm3 / h, of which 2700Nm3 / h nitrogen directly enters the nitrogen channel of the main heat exchanger to exchange heat with the return gas, liquefies in the main heat exchanger, cools down to 81.1K, and throttles through the V6y valve After reaching about 3atm, it will be sent out as a product. Based on this working condition, the equivalent heat exchange network parameters of the multi-stream heat exchanger are estimated. The parameters of the eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com