A detection device and method for detecting the airtightness of canned food

A technology of canned food and detection device, which is used in fluid tightness test, measurement device, and liquid/vacuum degree for liquid tightness measurement, etc. and other problems to achieve the effect of reducing the impact, reducing the number of inspections, and reducing the number of batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

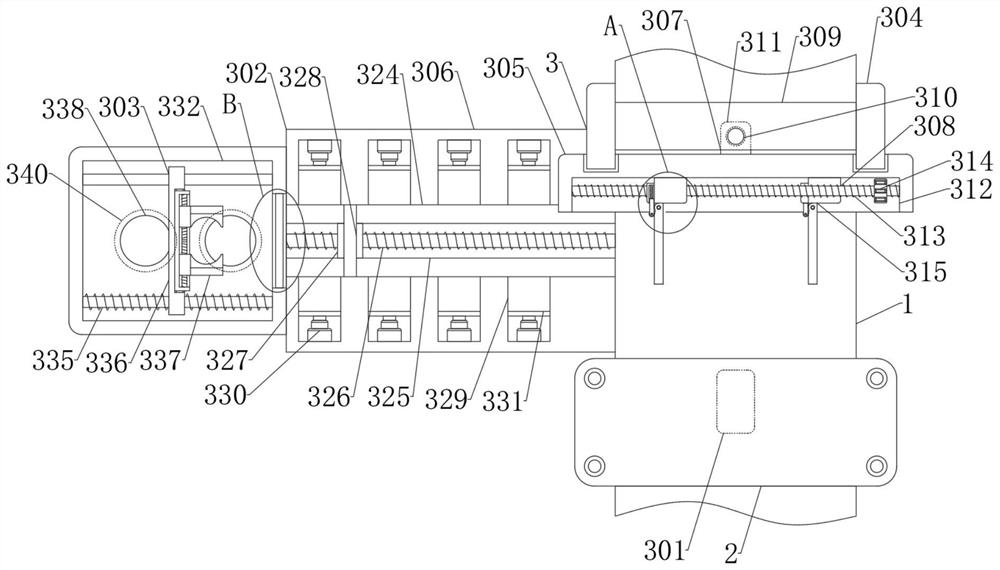

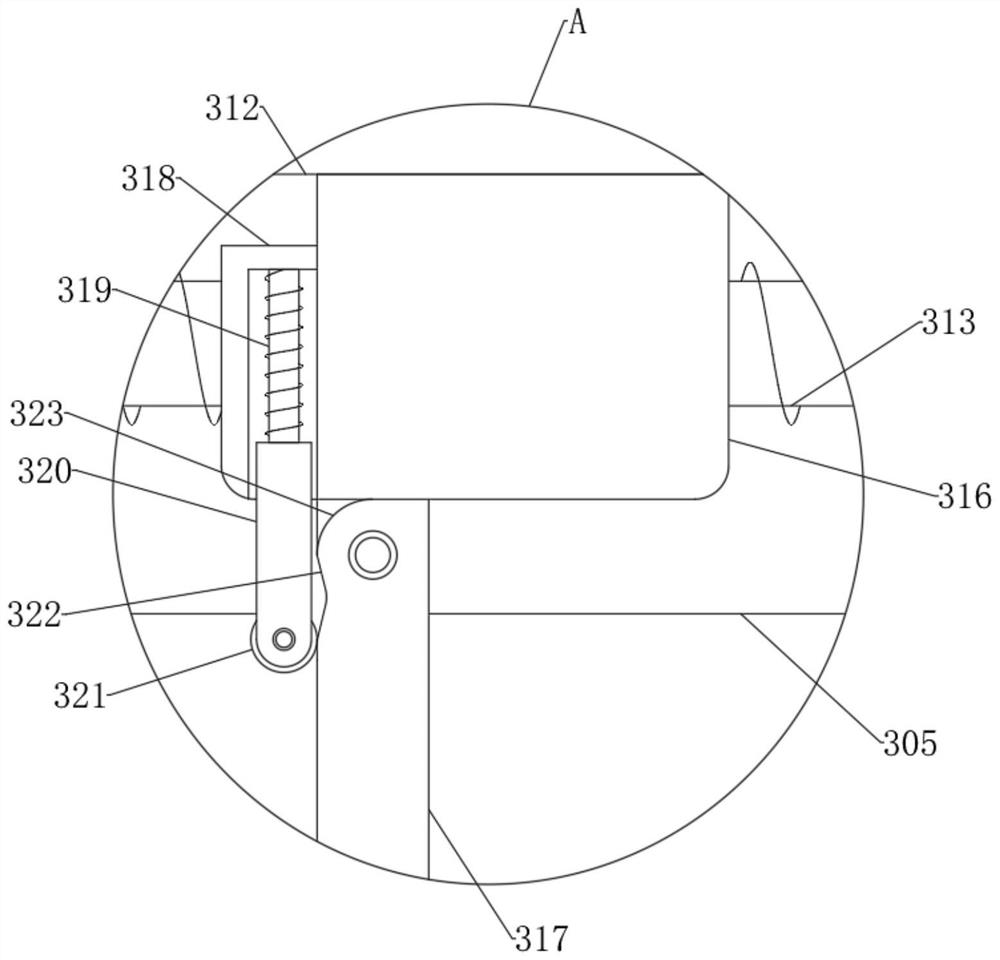

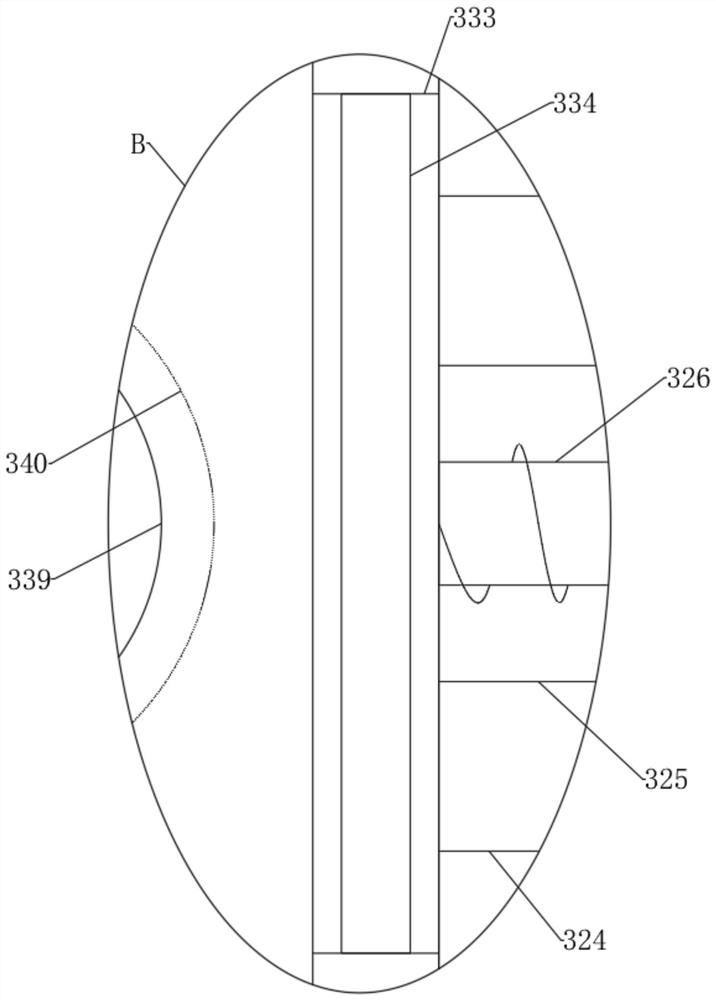

[0037] Such as Figure 1 to Figure 3 As shown, the present invention provides a detection device for detecting the airtightness of canned food, including a plurality of food transportation lines 1 arranged in parallel and a filling method for filling food on the plurality of food transportation lines 1 Device 2, multiple food transportation lines 1 are equipped with a classification detection device 3 for detecting the air tightness of canned food, and the classification detection device 3 determines the canned food through the classification detection of the filling device 2 and canned food Whether the food airtightness is qualified;

[0038] The grading detection device 3 includes a plurality of sensing elements 301 arranged on the filling device 2 for measuring filling pressures on different food transportation lines 1 and a plurality of induction elements 301 arranged on different food transportation lines 1 for isolating unqualified canned foods. A food isolation structu...

Embodiment 2

[0090] The present invention also provides a detection method of a detection device for detecting the airtightness of canned food, comprising the steps of,

[0091] S100, the food is transported on the food transportation line and filled by the filling device, and at the same time, the filling pressure of the filling device is detected by the sensing element, and compared with the preset pressure value to determine whether the filling pressure is qualified;

[0092] S200, when the sensing element detects that the filling pressure is normal, the food isolation structure and the airtight detection structure do not act; when the sensing element detects that the filling pressure exceeds the preset pressure value range, the food isolation structure acts to intercept through the transfer baffle Canned food that passes through the filling device during the inspection period and is transferred to the airtight inspection structure through the transfer structure for separate inspection; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com