Moisture-absorbing, sweat-releasing and antibacterial nylon four-way stretch fabric and preparation method thereof

A moisture-absorbing and sweat-wicking, four-way elastic technology, which is applied in the field of fabric processing, can solve the problems of poor moisture-wicking and sweat-wicking effects of moisture-wicking and antibacterial fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

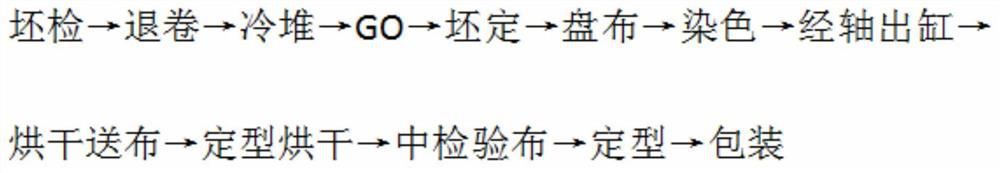

Image

Examples

Embodiment 1

[0036] A kind of moisture-absorbing, sweat-wicking and antibacterial nylon four-way stretch fabric and preparation method thereof

[0037] The preparation method of the moisture-wicking and antibacterial nylon four-way stretch fabric comprises the following steps:

[0038] Step 1, blank inspection and unwinding: carry out blank inspection and unwinding of the nylon four-sided stretch fabric;

[0039] Step 2, cold stacking: put the gray fabric in the cold stacking liquid for 24 hours, the temperature is 60°C, the pressure of the paddle is 2kgf / cm2, and the speed is 50m / min; the cold stacking liquid includes the first cold stacking liquid and The second cold pile liquid; the raw material of above-mentioned first cold pile liquid comprises: 30g / L concentration is the liquid caustic soda of 32%, 10g / L emulsifier 550, 3g / L dispersant, 6g / L degreasing agent, 0.8g / L L penetrating agent PT-70N; the raw materials of the second cold stack liquid include: 30g / L liquid caustic soda, 10g / ...

Embodiment 2

[0049] A kind of moisture-absorbing, sweat-wicking and antibacterial nylon four-way stretch fabric and preparation method thereof

[0050] The preparation method of the moisture-wicking and antibacterial nylon four-way stretch fabric comprises the following steps:

[0051] Step 1, blank inspection and unwinding: the nylon four-way stretch gray cloth is subjected to blank inspection and unwinding treatment; the weaving raw materials of the nylon four-way stretch gray cloth include 100 parts of nylon fiber, 12 parts of spandex fiber, and 0.5 part of polyolefin fiber , 20 parts of cotton fiber and 5 parts of bamboo fiber;

[0052] Step 2, cold stacking: put the gray fabric in the cold stacking liquid for 26 hours, the temperature is 55°C, the pressure of the rolling machine is 1.2kgf / cm2, and the speed is 40m / min; the cold stacking liquid includes the first cold stacking liquid And the second cold pile liquid; the raw material of above-mentioned first cold pile liquid comprises:...

Embodiment 3

[0063] A kind of moisture-absorbing, sweat-wicking and antibacterial nylon four-way stretch fabric and preparation method thereof

[0064] The preparation method of the moisture-wicking and antibacterial nylon four-way stretch fabric comprises the following steps:

[0065] Step 1, blank inspection and unwinding: the nylon four-way stretch gray cloth is subjected to blank inspection and unwinding treatment; the weaving raw materials of the nylon four-way stretch gray cloth include 100 parts of nylon fiber, 22 parts of spandex fiber, and 5.5 parts of polyolefin fiber , 45 parts of cotton fiber and 12 parts of bamboo fiber;

[0066] Step 2, cold stacking: put the gray fabric in the cold stacking liquid for 26 hours, the temperature is 65°C, the pressure of the rolling machine is 2.8kgf / cm2, and the speed is 60m / min; the cold stacking liquid includes the first cold stacking liquid And the second cold pile liquid; the raw material of above-mentioned first cold pile liquid comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com