High-nickel single-crystal ternary precursor and preparation method thereof

A precursor and single crystal technology, applied in the field of high nickel single crystal ternary precursor and its preparation, can solve the problems of inappropriate primary particle thickness and material capacity decay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

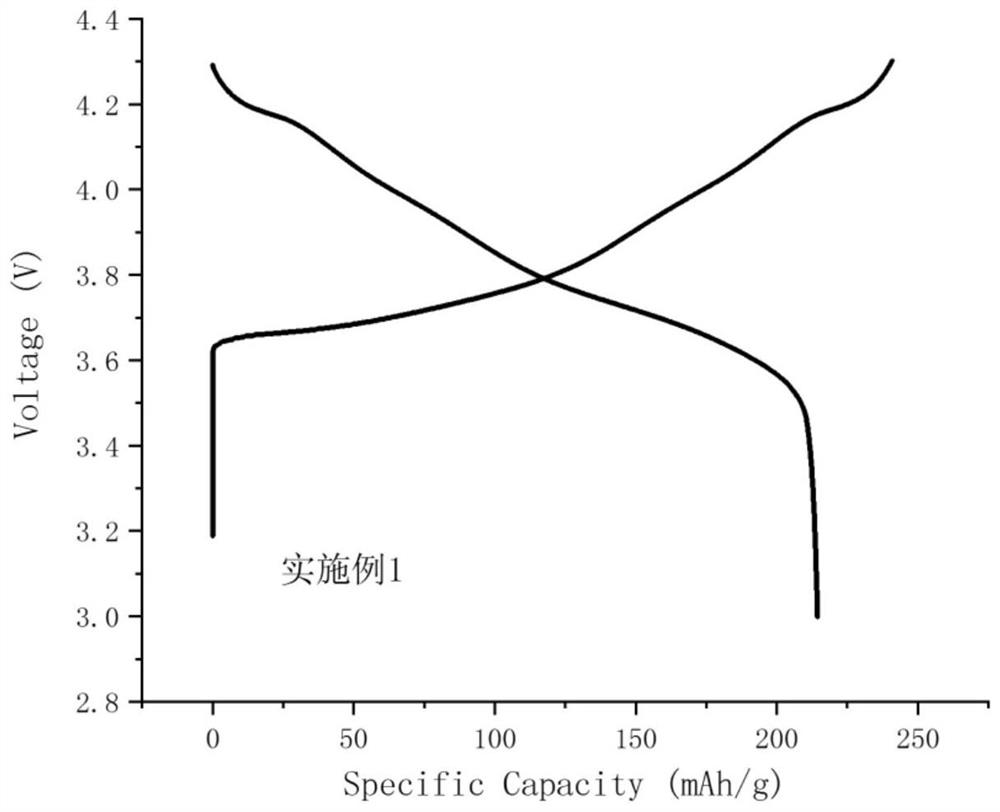

Examples

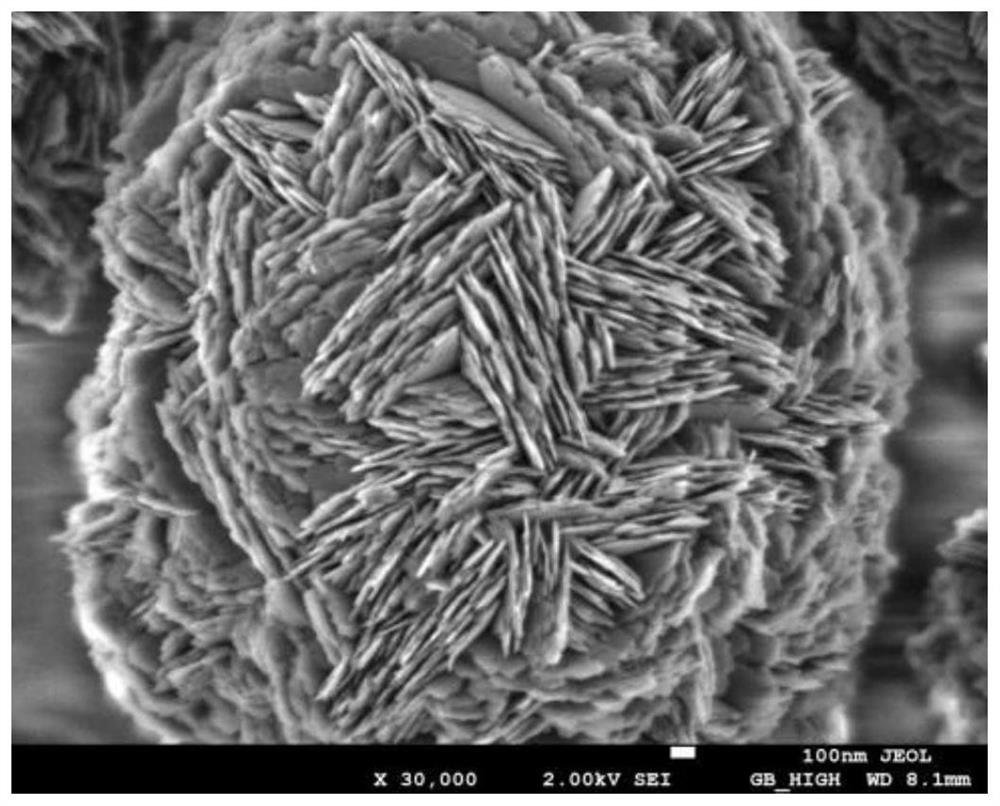

Embodiment 1

[0042] A kind of preparation method of high-nickel single crystal ternary precursor, described preparation method comprises the following steps:

[0043] Step 1. Pretreatment stage: Ni 2+ 、Co 2+ , Mn 2+ Potassium and three oxalato manganese (Ⅲ) according to the general formula Ni 0.85 co 0.09 mn 0.06 (OH) 2 Prepare a soluble mixed salt solution in the corresponding element molar ratio, wherein, the Mn of potassium trioxalatomanganate (Ⅲ) 3+ with Mn 2+ The molar ratio of the salt solution is 3, so as to refine the primary particles of the secondary particles and increase the specific surface area; the pH value of the mixed salt solution is 4.5-5.5.

[0044] Ni in the mixed salt solution described in step 1 2+ The concentration is 100g / L, Co 2+ The concentration is 10.5 g / L, Mn 2+ The concentration is 6.5g / L, Ni 2+ 、Co 2+ and Mn 2+ The total concentration of the three metal ions was 117 g / L.

[0045] Prepare a sodium hydroxide solution with a mass fraction of 32% a...

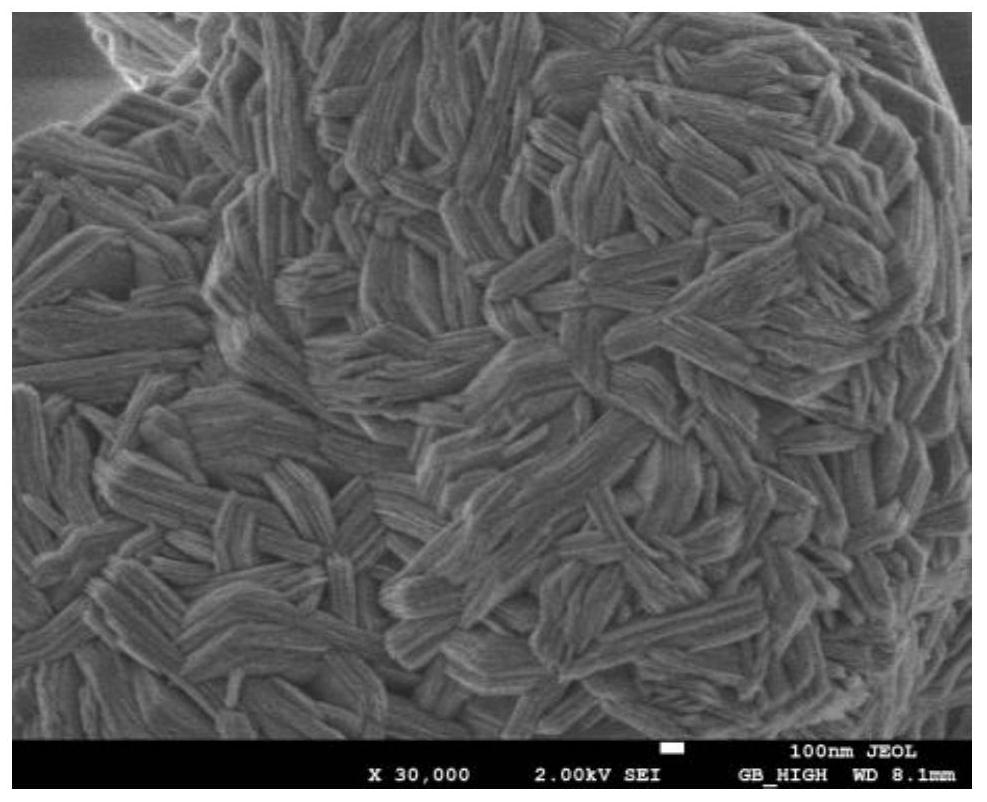

Embodiment 2

[0054] A kind of preparation method of high-nickel single crystal ternary precursor, described preparation method comprises the following steps:

[0055] Step 1. Pretreatment stage: Ni 2+ 、Co 2+ , Mn 2+ Potassium and three oxalato manganese (Ⅲ) according to the general formula Ni 0.92 co 0.05 mn 0.03 (OH) 2 Prepare a soluble mixed salt solution in the corresponding element molar ratio, wherein, the Mn of potassium trioxalatomanganate (Ⅲ) 3+ with Mn 2+ The molar ratio of the salt solution is 2, so as to refine the primary particles of the secondary particles and increase the specific surface area; the pH value of the mixed salt solution is 4.5-5.5.

[0056] Ni in the mixed salt solution described in step 1 2+ The concentration is 108 g / L, Co 2+ The concentration is 6 g / L, Mn 2+ Concentration of 3 g / L, Ni 2+ 、Co 2+ and Mn 2+ The total concentration of the three metal ions was 117g / L.

[0057] Prepare a sodium hydroxide solution with a mass fraction of 32% as a prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com