Method for manufacturing imitated bone component by using wastes, and imitated bone component

A waste and bone imitation technology, applied in the fields of materials science, mechanics, bionics and ecological environment, can solve the problems of low structural strength and stiffness, low flexural strength and stiffness, and difficulty in recycling waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

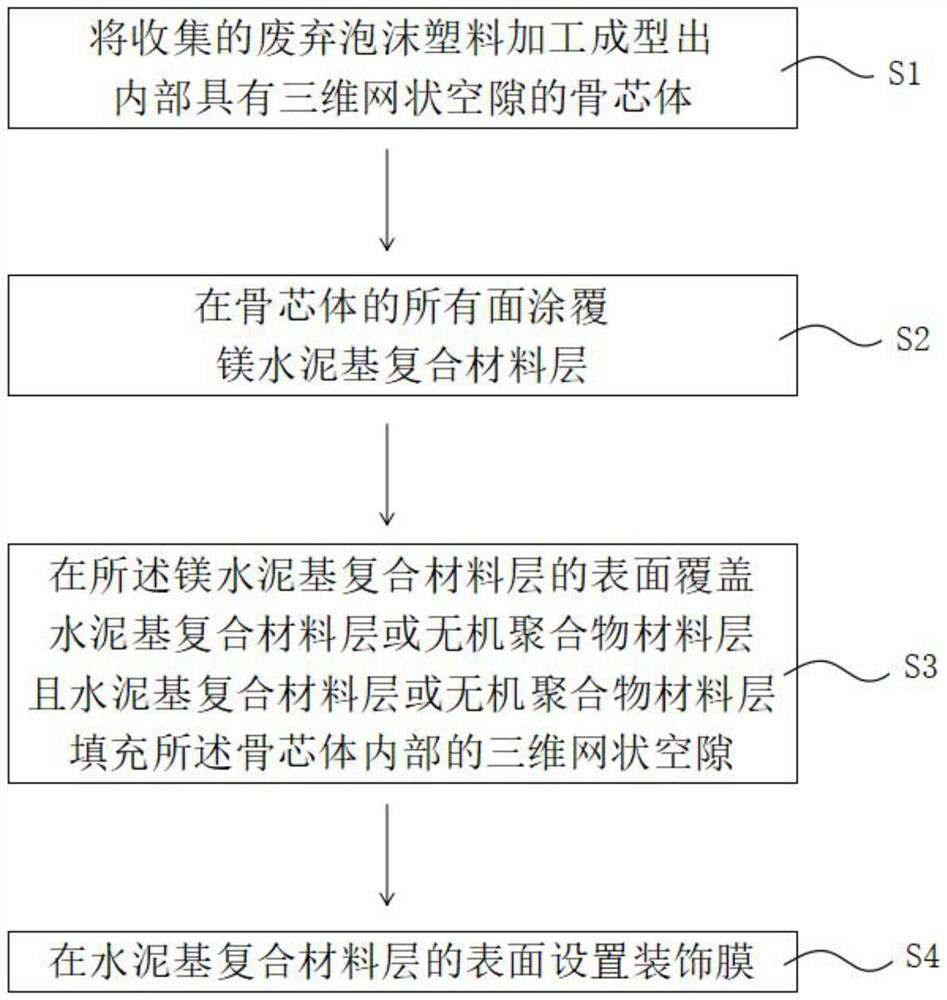

[0059] Such as figure 1 As shown, a method of using waste foam plastics to manufacture bone-like components specifically includes the following steps:

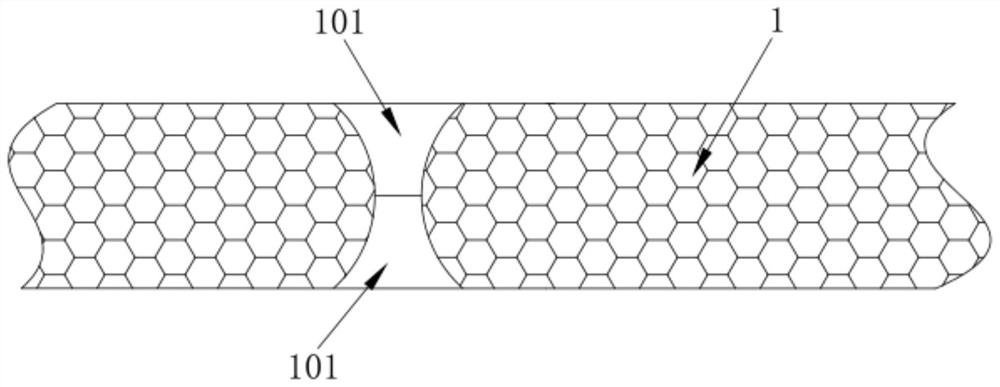

[0060] Step S1 , processing and molding the collected waste foam plastics into a bone core body 1 with three-dimensional network voids inside.

[0061] In the first specific implementation of step S1, it specifically includes the following steps: crush waste foamed plastics into crumbs below 10 mm, mix the crumbs with a binder and put them into a bone core mold for pressing to form a three-dimensional Bone core body 1 with reticular voids. Specifically, all kinds of waste foam plastics that are mixed and recycled are directly cleaned, dried, and crushed into debris below 10 mm without classification, and then coated with an organic adhesive and then pressed with a bone core mold for cementation; After the inorganic type binder is pressed with a bone core mold, it is solidified and formed.

[0062] The first implementation m...

Embodiment 2

[0118] Taking the bone imitation safety door as an example, the method for manufacturing the bone imitation safety door provided by the embodiment of the present application is described in detail below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com